A special grip sensor for an electric iron

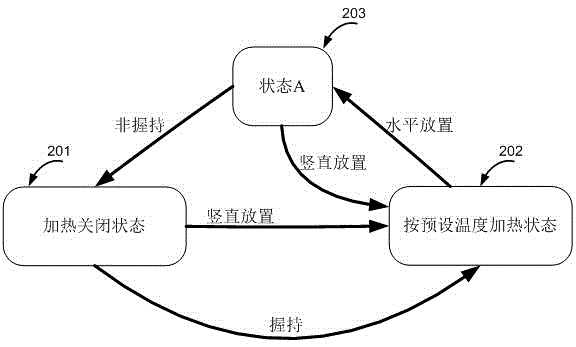

An inductive sensor and electrode technology, applied in the field of sensors, can solve the problems of electric iron safety, heat accumulation, lifting, etc., and achieve the effect of simple and convenient implantation, solving safety problems, and good grip feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

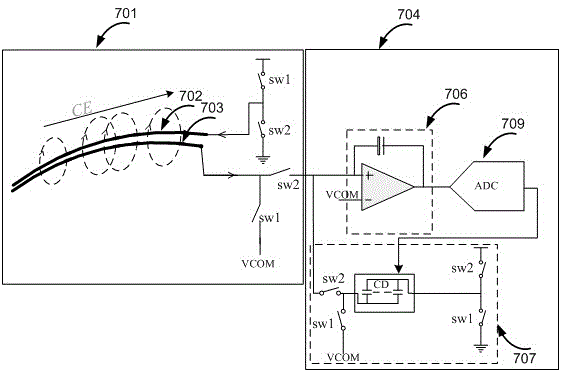

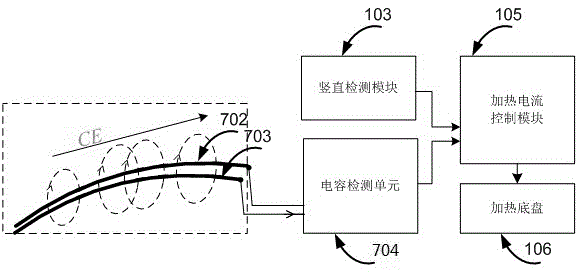

[0020] refer to figure 1 , the present invention includes a signal generating electrode 702 and a signal receiving electrode 703 composed of two metal wires, a capacitance integration input module 701 composed of two electrodes in conjunction with a switch sw1 and a switch sw2, and a signal integration module 706, an analog-to-digital conversion module 709 and The negative integral input module 707 constitutes the capacitance detection unit 704 .

[0021] The switches sw1 and sw2 represent two non-overlapping switches that are turned on alternately. During the conduction period of the switch sw1, the capacitor CE between the two electrodes 702 and 703 is charged. After the switch sw1 is turned off, the switch sw2 is conducted during the conduction period. Transferred to the signal integration module 706, the switching timing of the negative integration input module 707 is opposite to that of the capacitance integration input module 701, therefore, the charge in the capacitance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com