Movable bulk material loader

A loader and mobile technology, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problems of complex mechanical arm structure, complex loader, poor rigidity, etc., to achieve The effect of large conveying torque, easy transshipment, high strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

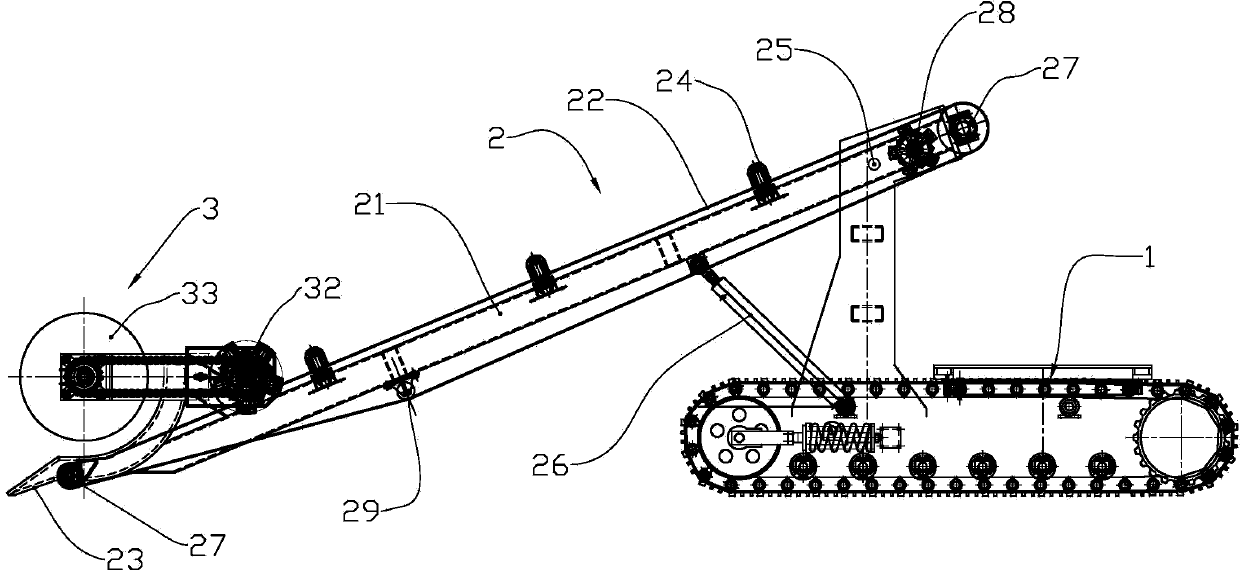

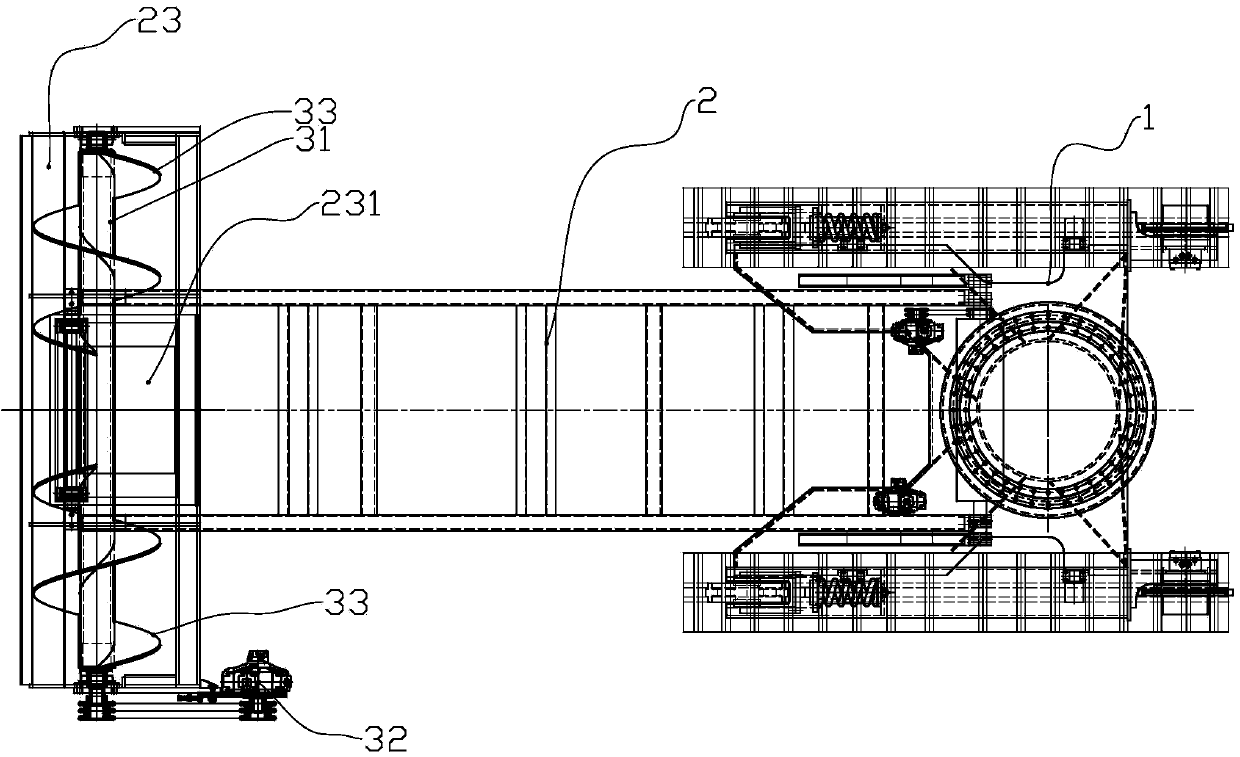

[0025] Such as Figure 1 to Figure 2 As shown, a mobile bulk loader includes three parts: a vehicle body 1, a conveyor belt mechanism 2 and a reclaiming mechanism 3, which will be described in detail below.

[0026] The vehicle body 1 is a crawler-type hydraulically driven vehicle body, which adopts hydraulic drive and has high dynamic performance. The vehicle body is also commonly used in engineering vehicles. For example, a hydraulic crawler excavator is such a body. Install a post upright on the body for mounting the frame.

[0027] The conveyor belt mechanism 2 includes a frame 21, a transmission belt 22, a bucket 23 and an idler roller assembly 24, wherein the frame 21 is a rectangular frame formed by welded section steel, including beams and longitudinal beams, and is the basis for installing the conveyor belt and the reclaiming mechanism. The middle and upper part of the frame 21 is rotatably mounted on the vehicle body through a pin shaft 25 to form a hinge relations...

Embodiment 2

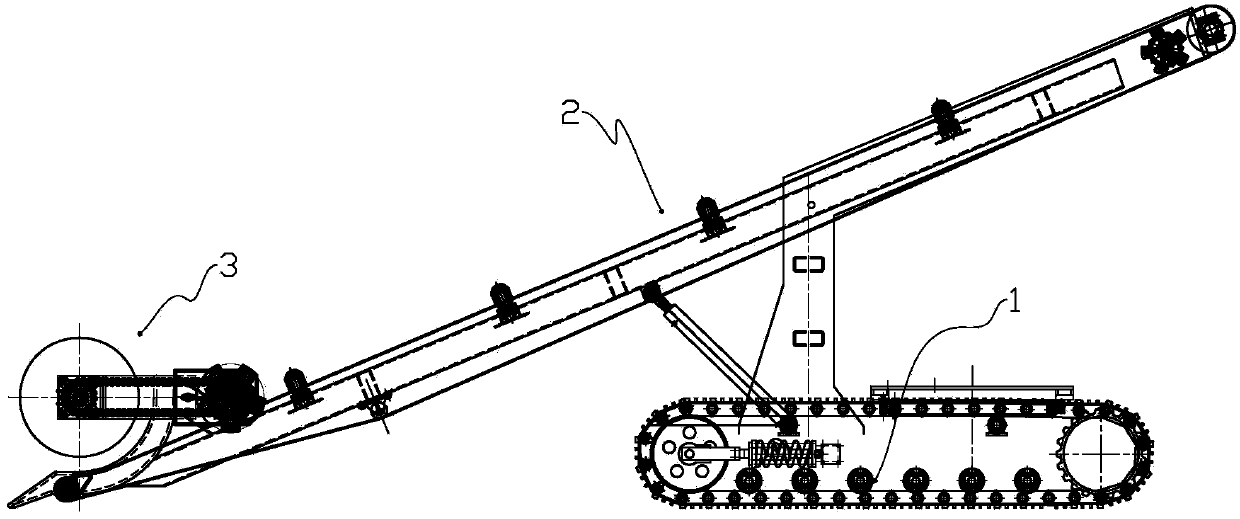

[0034] Such as image 3 As shown, the difference from Embodiment 1 lies in the difference in the installation relative positions of the frame and the vehicle body, specifically the difference in the positions of the hinge point and the oil cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com