Vehicle second-level oil pump control system and method

A two-stage engine oil pump and control system technology, which is applied in the direction of controlling the pressure of the lubricant and the pressure lubrication of the lubricating pump, can solve the problems of unfavorable engine, affecting the performance of engine oil lubrication and ventilation, etc., to ensure fuel economy, The effect of improving engine performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

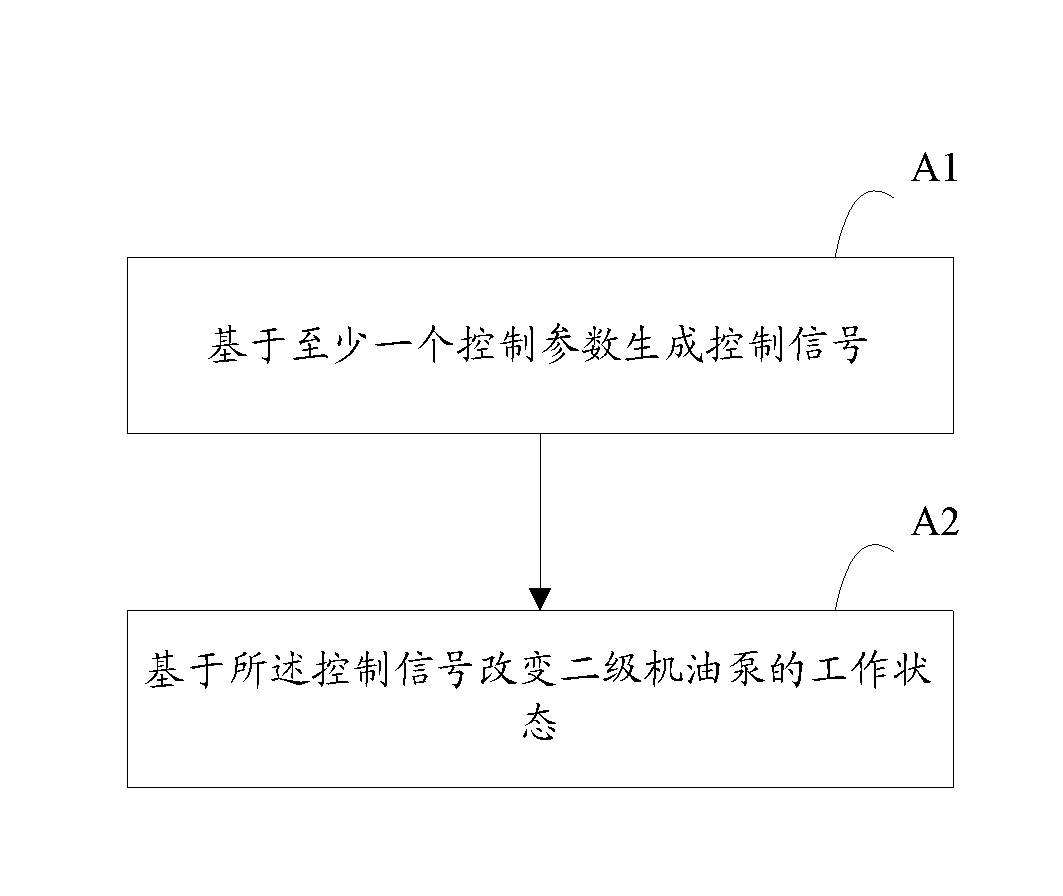

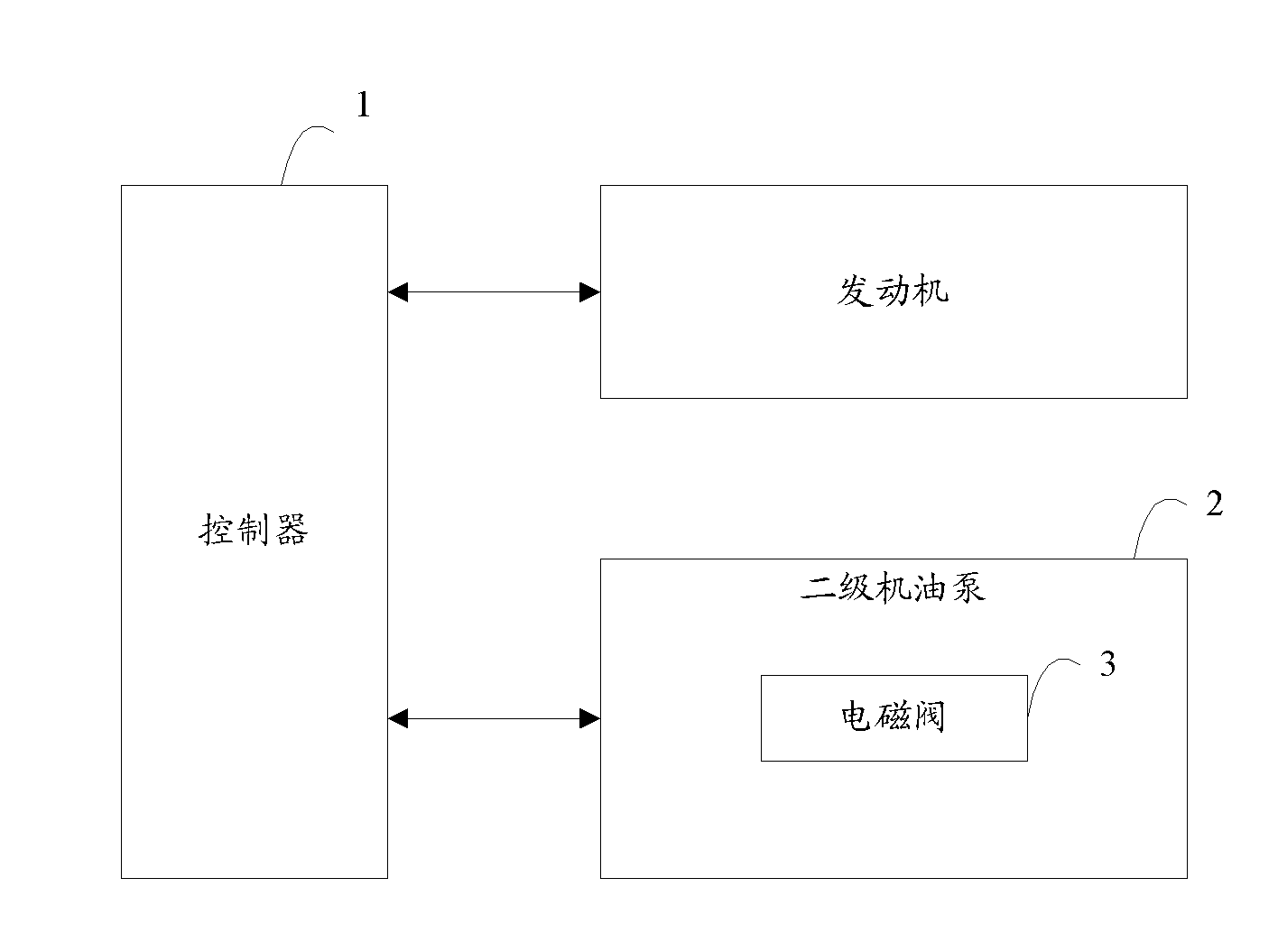

[0039] figure 1 is a schematic structural diagram of a vehicle secondary oil pump control system according to an embodiment of the present invention. Such as figure 1 As shown, the vehicle secondary oil pump control system disclosed in the present invention includes a controller 1 (such as the vehicle's engine controller ECM) and a secondary oil pump 2 . Wherein, the controller 1 generates a control signal based on at least one control parameter, and transmits the control signal to the secondary oil pump 2 . The secondary oil pump 2 changes its working state based on the received control signal.

[0040] Preferably, in the vehicle secondary oil pump control system disclosed in the present invention, the working state includes a high-pressure mode and a low-pressure mode.

[0041] Preferably, in the vehicle secondary oil pump control system disclosed in the present invention, the secondary oil pump 2 includes a solenoid valve 3, and the secondary oil pump 2 controls the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com