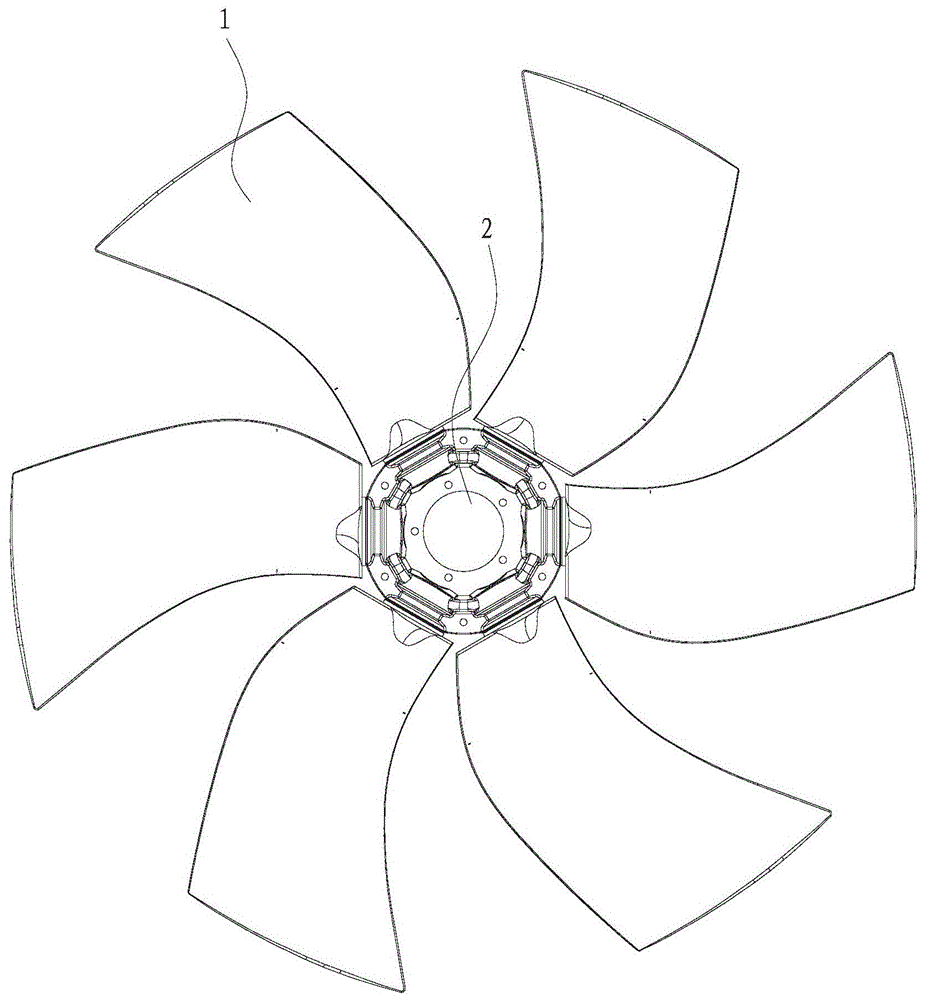

fan

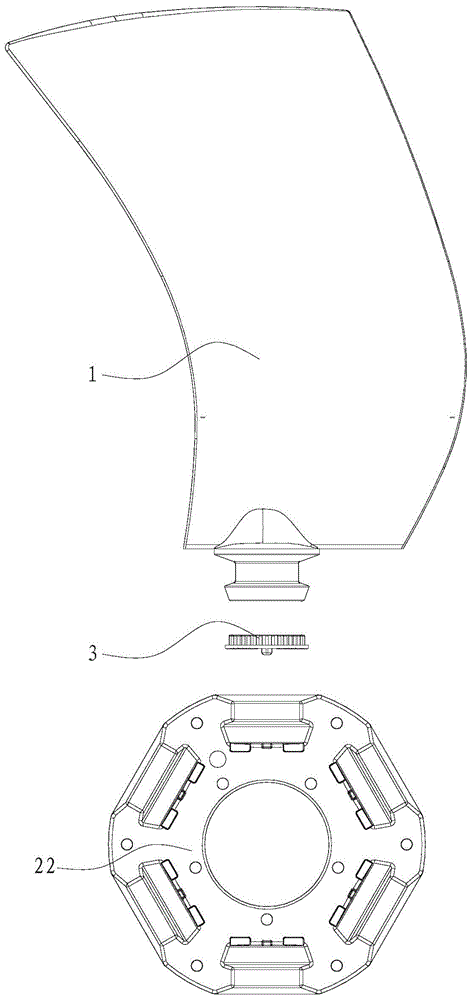

A technology for fans and angle adjusters, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc. problems, to achieve the effect of high angle adjustment accuracy, simple adjustment, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

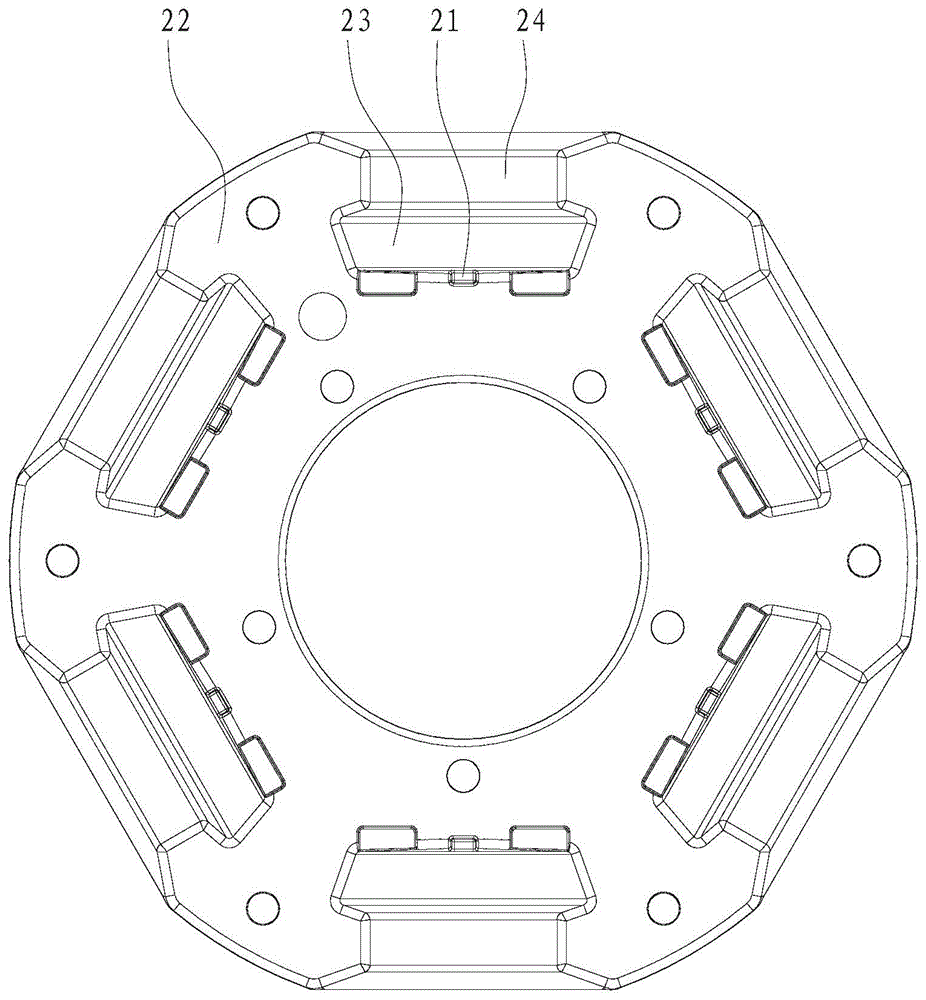

[0032] There are 10 angle adjusters 3, and the angle adjustment teeth 311 of each angle adjuster 3 are 36. When the angle adjustment teeth 311 are in the same position as the blade 1, the positions of the angle adjustment columns 33 are arranged in sequence with an angle gradient of 1 degree . Thus, a full 360-degree angle adjustment with a minimum angle of 1 degree can be realized.

Embodiment 2

[0034] There are 5 angle adjusters 3, and the angle adjustment teeth 311 of each angle adjuster 3 are 72. When the angle adjustment teeth 311 and the blade 1 are in the same position, the positions of the angle adjustment columns 33 are arranged in sequence with an angle gradient of 1 degree . Thus, a full 360-degree angle adjustment with a minimum angle of 1 degree can be realized.

Embodiment 3

[0036] There are 10 angle adjusters 3, and each angle adjuster 3 has 72 angle adjustment teeth 311. When the angle adjustment teeth 311 are in the same position as the blade 1, the positions of the angle adjustment columns 33 are sequentially adjusted with an angle gradient of 0.5 degrees. arrangement. Thus, a full 360-degree angle adjustment with a minimum angle of 0.5 degrees can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com