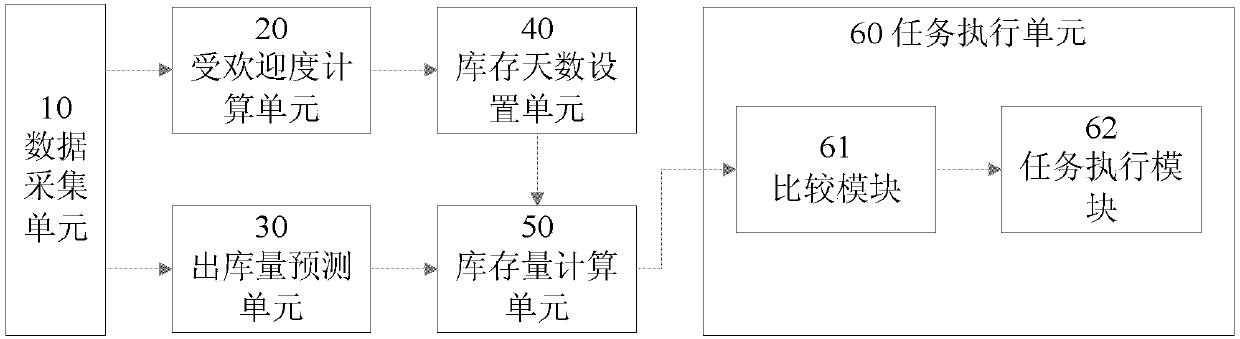

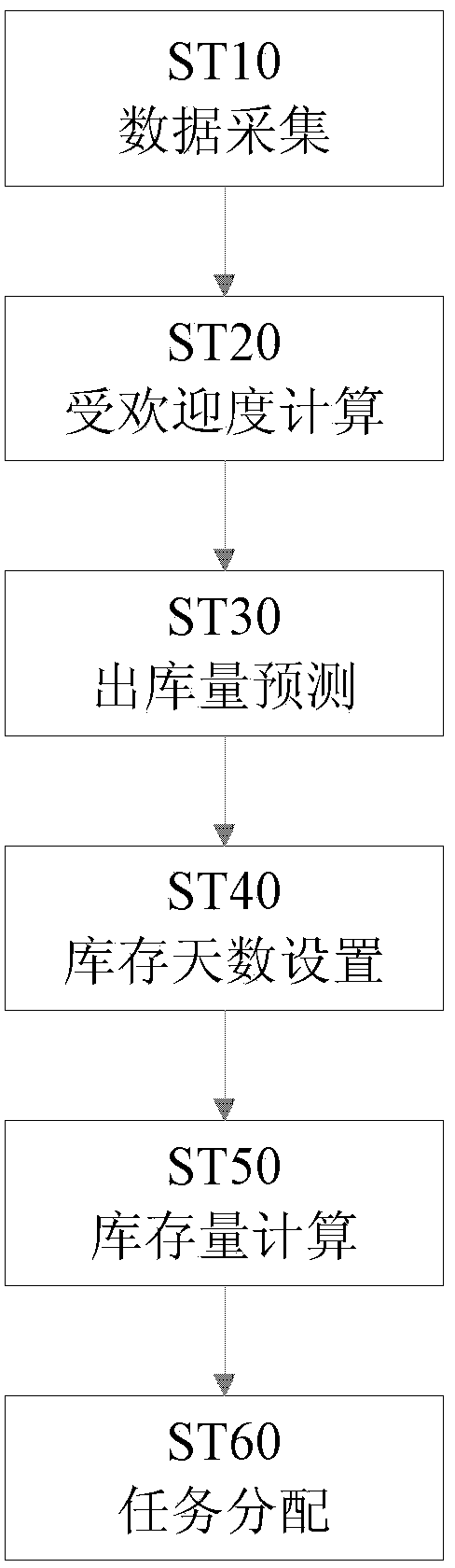

Processing system and method of warehouse inventory turnover

A processing system and processing method technology, applied in data processing applications, logistics, computing, etc., can solve problems such as many invalid operations, inability to update value settings, and the amount of replenishment of goods cannot meet expectations, to optimize utilization and reduce emergency replenishment. effect of goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

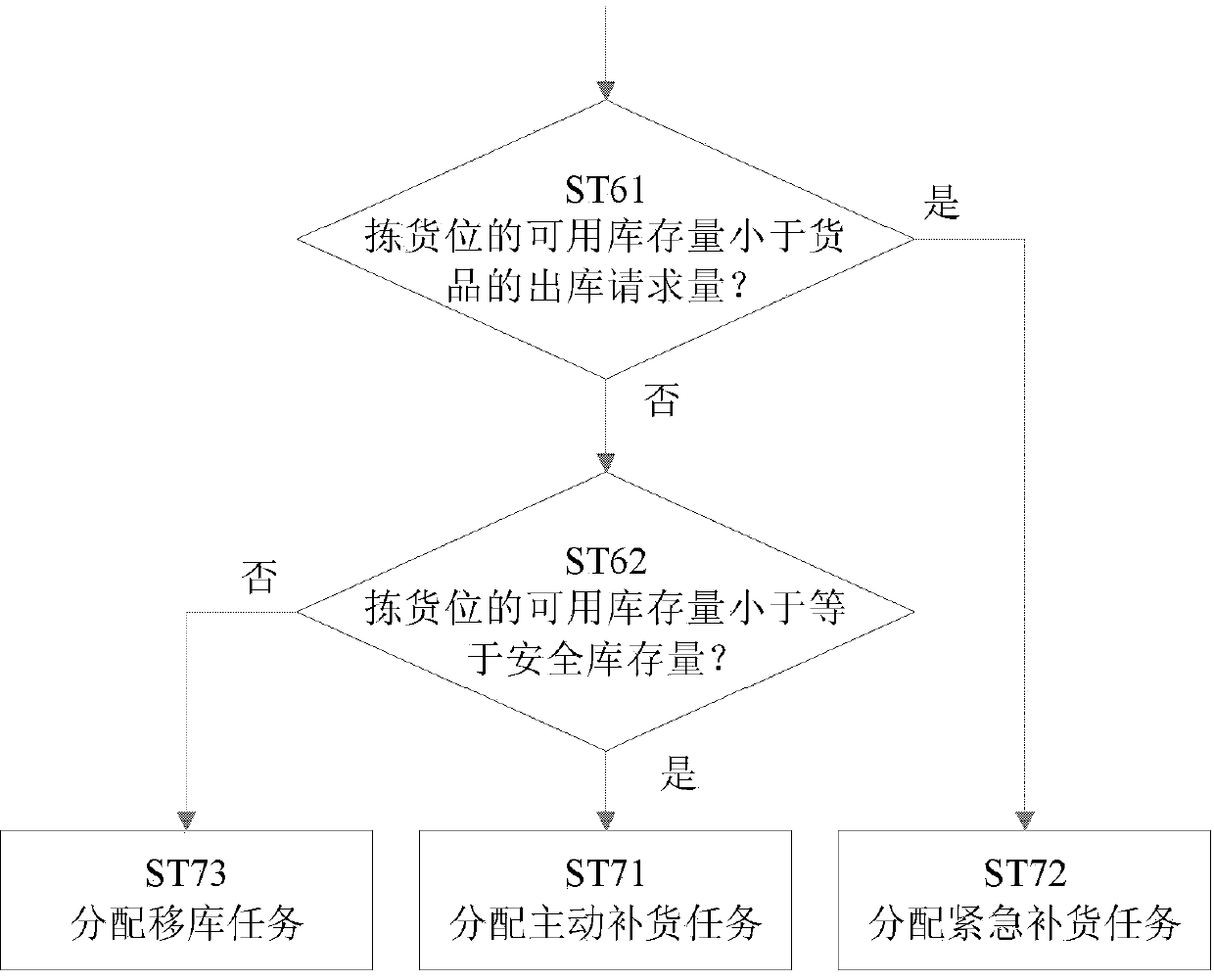

[0026] The term "active replenishment" as used herein refers to when the quantity of goods on the pick position is less than the safety stock, regardless of whether there is a All orders for this item will be assigned replenishment tasks. As used herein, the term "emergency replenishment" refers to a replenishment task assigned according to an order when a safety stock is not set at the pick location, and the replenishment amount is the quantity of items required by the order.

[0027] As used herein, the term "days of safety stock" refers to the number of days that a predetermined minimum stock quantity can be used under the existing daily shipment level. The term "maximum days of inventory" as used herein refers to the upper limit of days of inventory.

[0028] The term "safety stock" as used herein refers to the amount of insurance reserves projected against uncertainties. The term "maximum inventory" as used herein refers to an upper limit reserve amount stipulated for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com