a window cleaning machine

A window cleaning machine and head cleaning technology, which is applied to window cleaning, cleaning equipment, household appliances, etc., can solve problems such as dirty shells, poor water and air separation, and affect the normal operation of window cleaning machines, achieving convenience Card connection, prevent sewage from being sucked into the suction port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific embodiments and accompanying drawings.

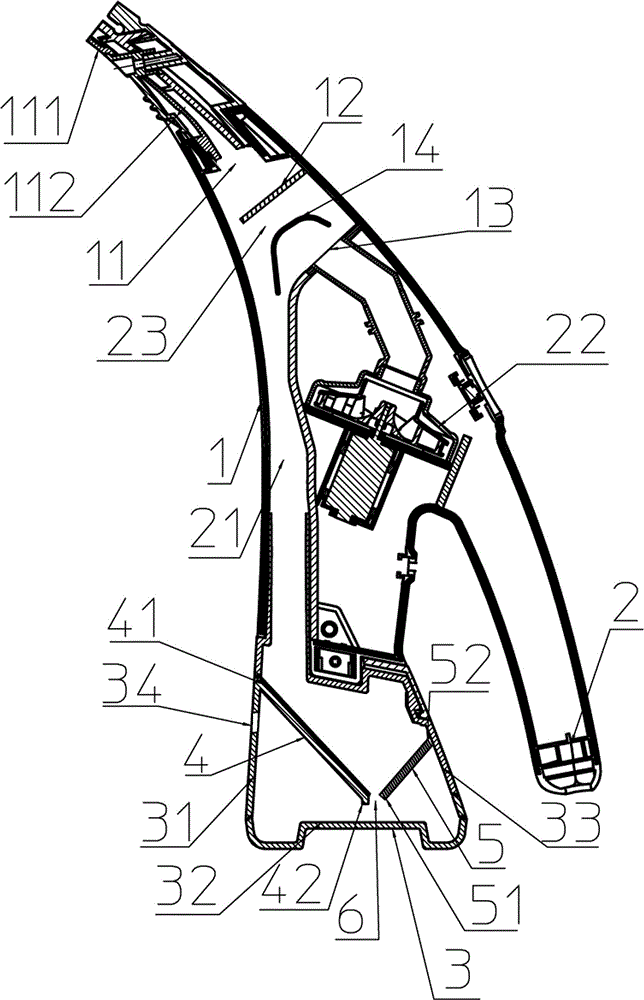

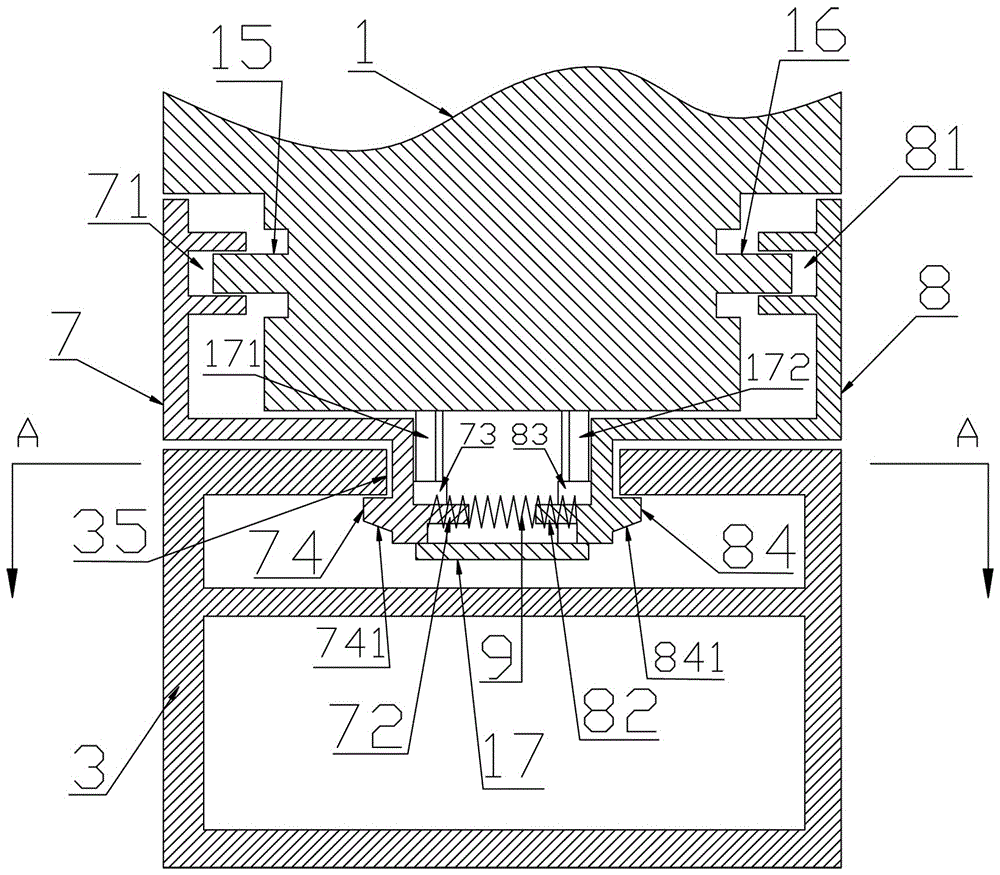

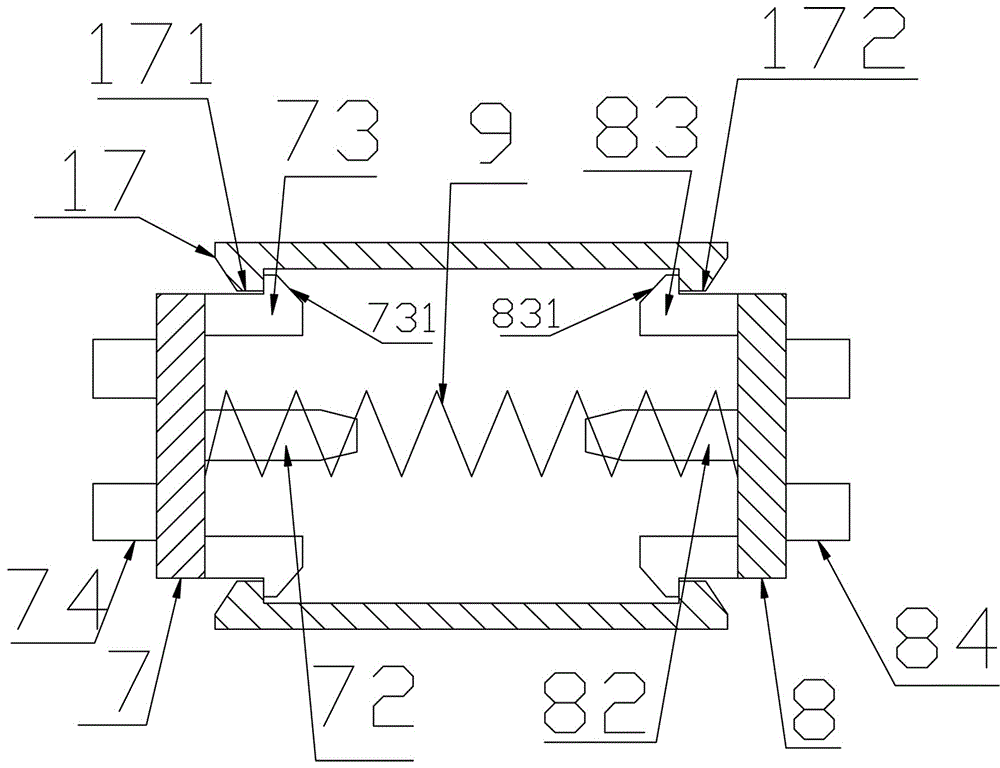

[0021] A window cleaning machine, such as figure 1 As shown, it includes a housing 1, the rear of the housing 1 is provided with a handle 2, the top of the front of the housing 1 is equipped with a wipe head 111 with an eraser strip, the water suction port 112 of the wipe head 111 is connected with the water on the top of the housing The air inlet 11 communicates, and a sewage collection box 3 is installed on the bottom of the housing 1. A water channel 21 capable of introducing water into the sewage collection box 3 is provided between the water gas inlet 11 and the sewage collection box 3. The water channel 21 is located at the bottom of the housing 1. The front part is also provided with a water-air separation chamber 23 between the water channel 21 and the water-air inlet 11, and a suction device 22 is also provided in the housing 1, and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com