A balloon fatigue test device

A technology of fatigue testing and balloons, applied in the direction of stents, etc., can solve problems such as expensive and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

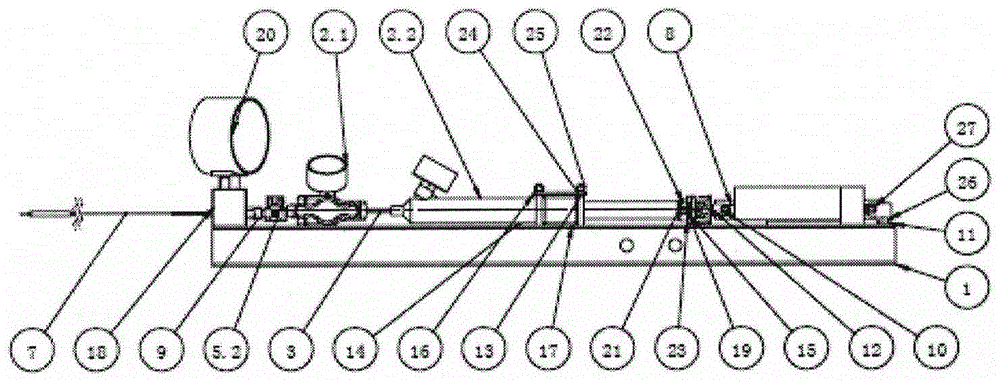

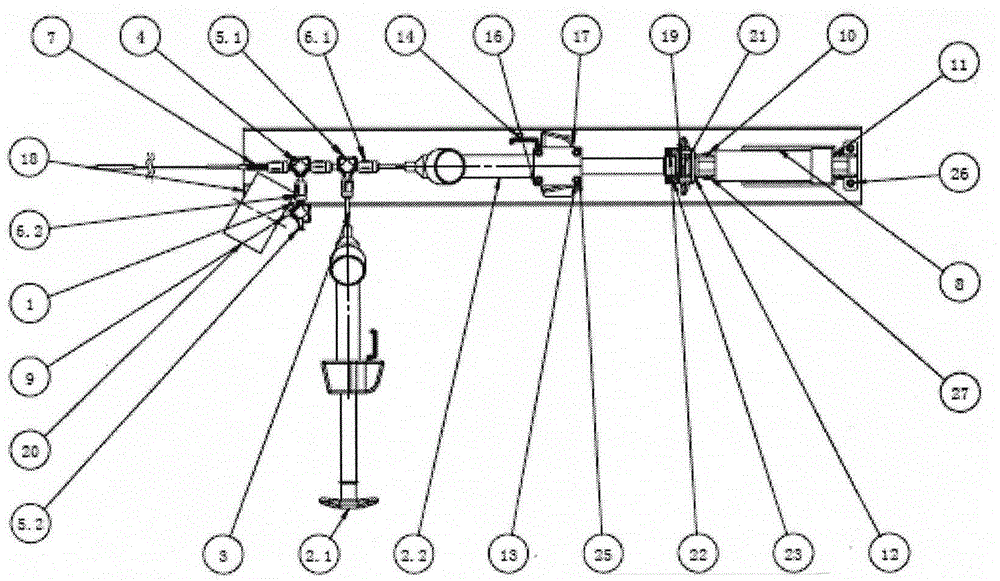

[0028] first press figure 1 , figure 2 As shown, it consists of machine base 1, balloon infusion pump 2.1, balloon expansion pump 2.2, hose 3, three-way 4, three-way valve 5.1 and 5.2, special joints 6.1 and 6.2, electric pusher 8, Luer joint 9 , Pin shaft 10, front support 11, rear support 12, stud 13, limit column 14, upper connection block 15, pressure plate 16, pump backing plate 17, valve seat 18, lower connection block 19, intelligent pressure A balloon fatigue testing device composed of the controller 20 and the standard parts 21-26 is assembled and connected; the connection is ensured firmly, and the system is reliable and leak-free at ≥ 30 atm.

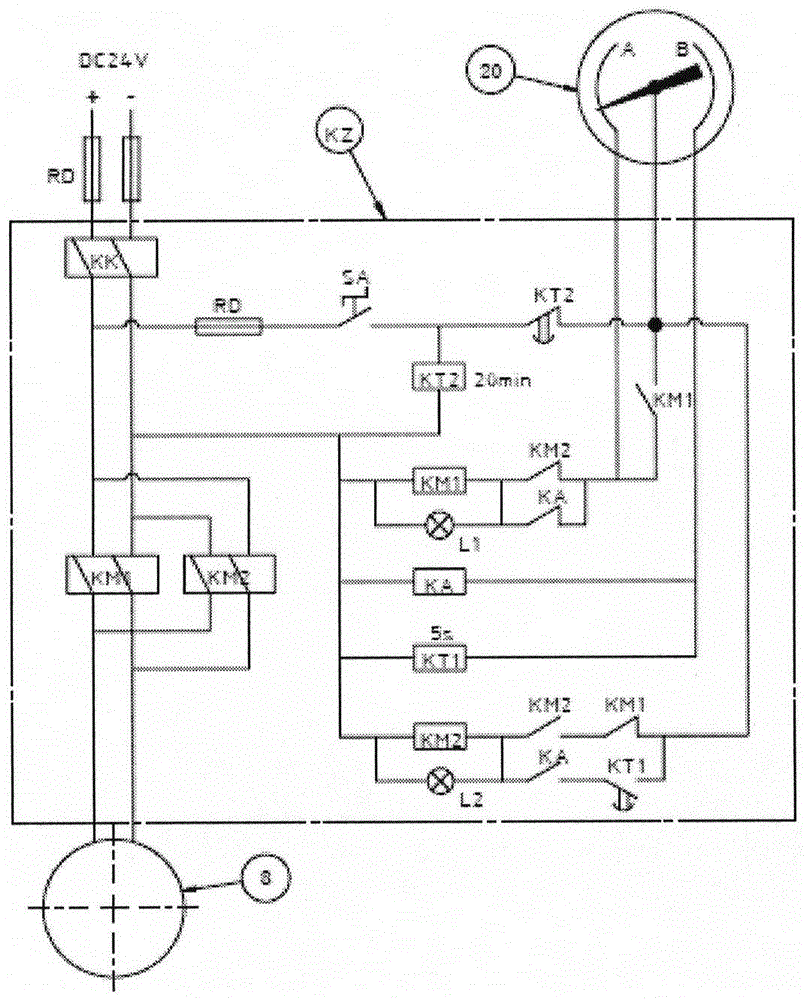

[0029] according to image 3 0~24V adjustable power supply, control box KZ, air switch KK, rotary switch SA, relay KM1, relay KM2, intermediate relay, delay on relay KT1, delay off relay KT2, indicator light L1 (red), The indicator light L2 (green), fuse RD, etc. are assembled and connected.

[0030] Connect the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com