Railway-vehicle air-conditioner air supplying and returning system

A rail vehicle and wind system technology, which is applied in the field of rail vehicle air-conditioning return air system, can solve problems such as uneven distribution, slow flow of air tissue in local areas, and the impact of air quality and comfort in the car, so as to achieve uniform distribution and improve air quality. In-vehicle air flow organization and the effect of optimizing the air environment in the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

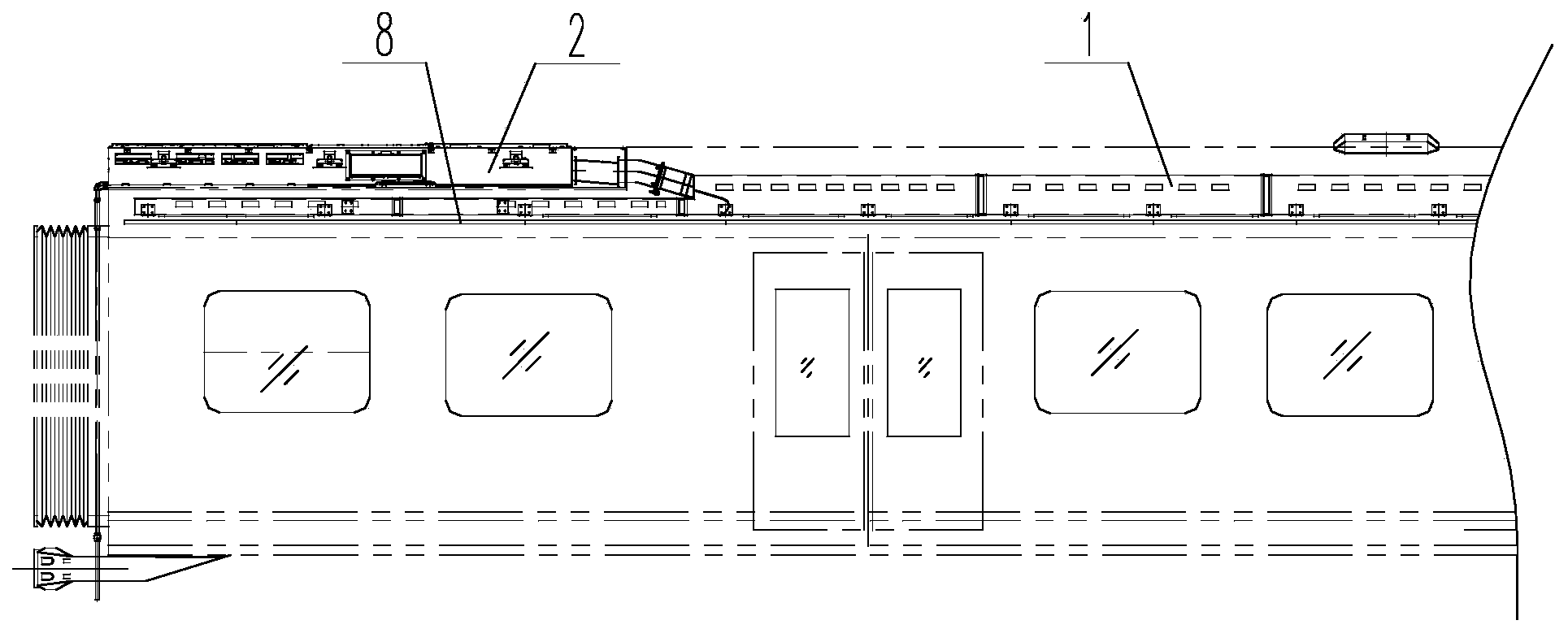

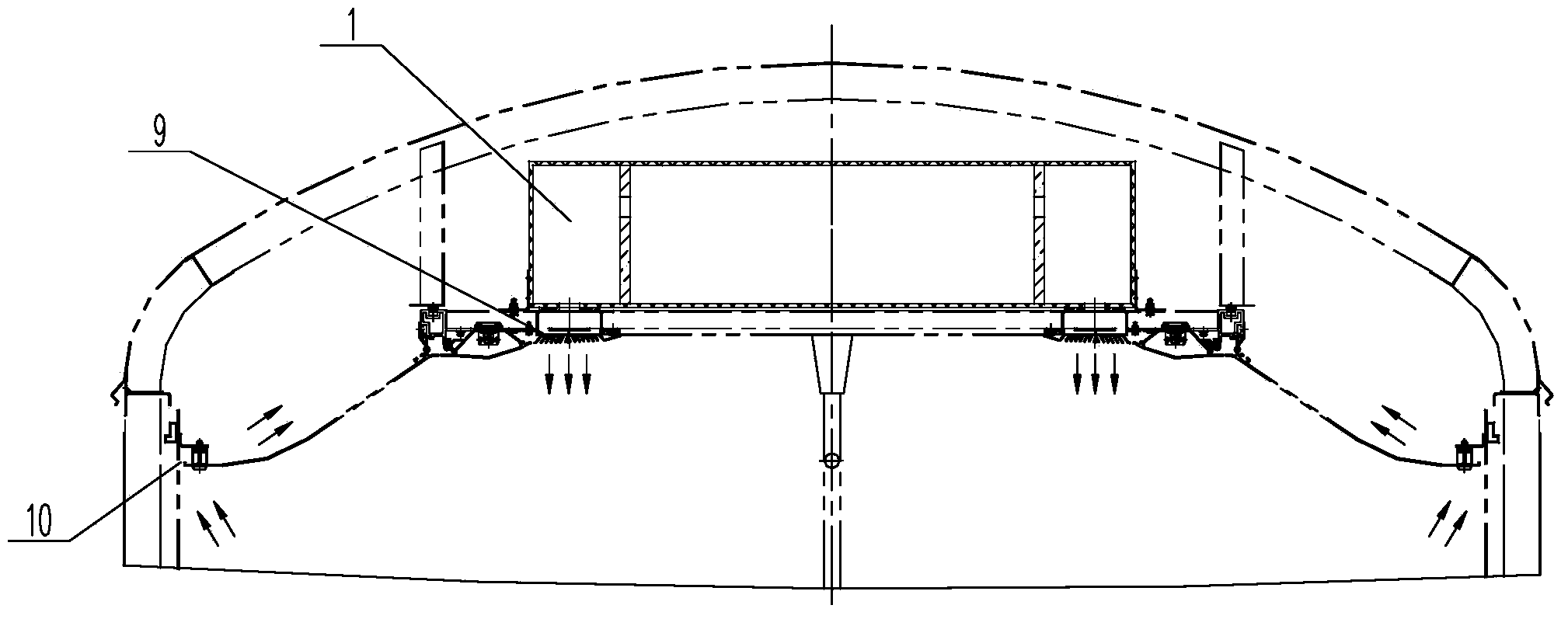

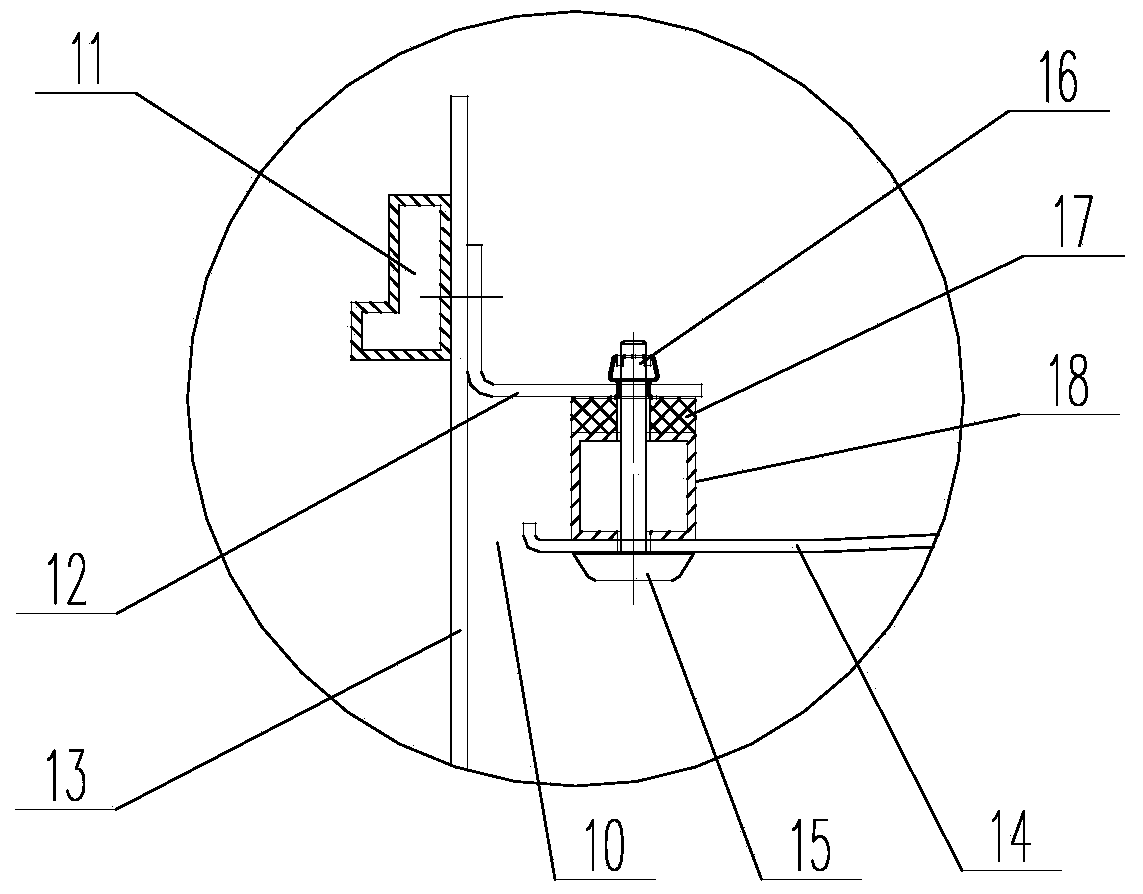

[0021] Such as Figure 1 to Figure 5 As shown, the rail vehicle air conditioner air return system in this embodiment includes air conditioners 2 ( figure 1 Only half of the car is drawn in the picture, and the structure of the other half is symmetrical to it), there is a through-type main air duct 1 above the flat roof of the passenger compartment, the air outlet of the air conditioner is connected to the main air duct 1, and the main air duct 1 passes through the delivery system below. The air outlet 9 supplies air to the passenger compartment; the air conditioner has a first return air outlet fixed on the flat roof of the vehicle end and a second return air outlet located above the flat roof of the vehicle end, and the lower edge of the side roof 14 of the passenger compartment is connected to the side wall frame 11 The connecting iron 12 is fixed, and a spacer 18 is arranged between the connecting iron 12 and the upper surface of the lower edge of the side top plate 14, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com