Remote axle-counting preliminary reset system and remote axle-counting preliminary reset method

A pre-reset, remote technology, applied in the direction of vehicle route interaction equipment, railway car body components, railway signal and safety, etc., can solve problems such as risks and achieve the effect of pre-reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

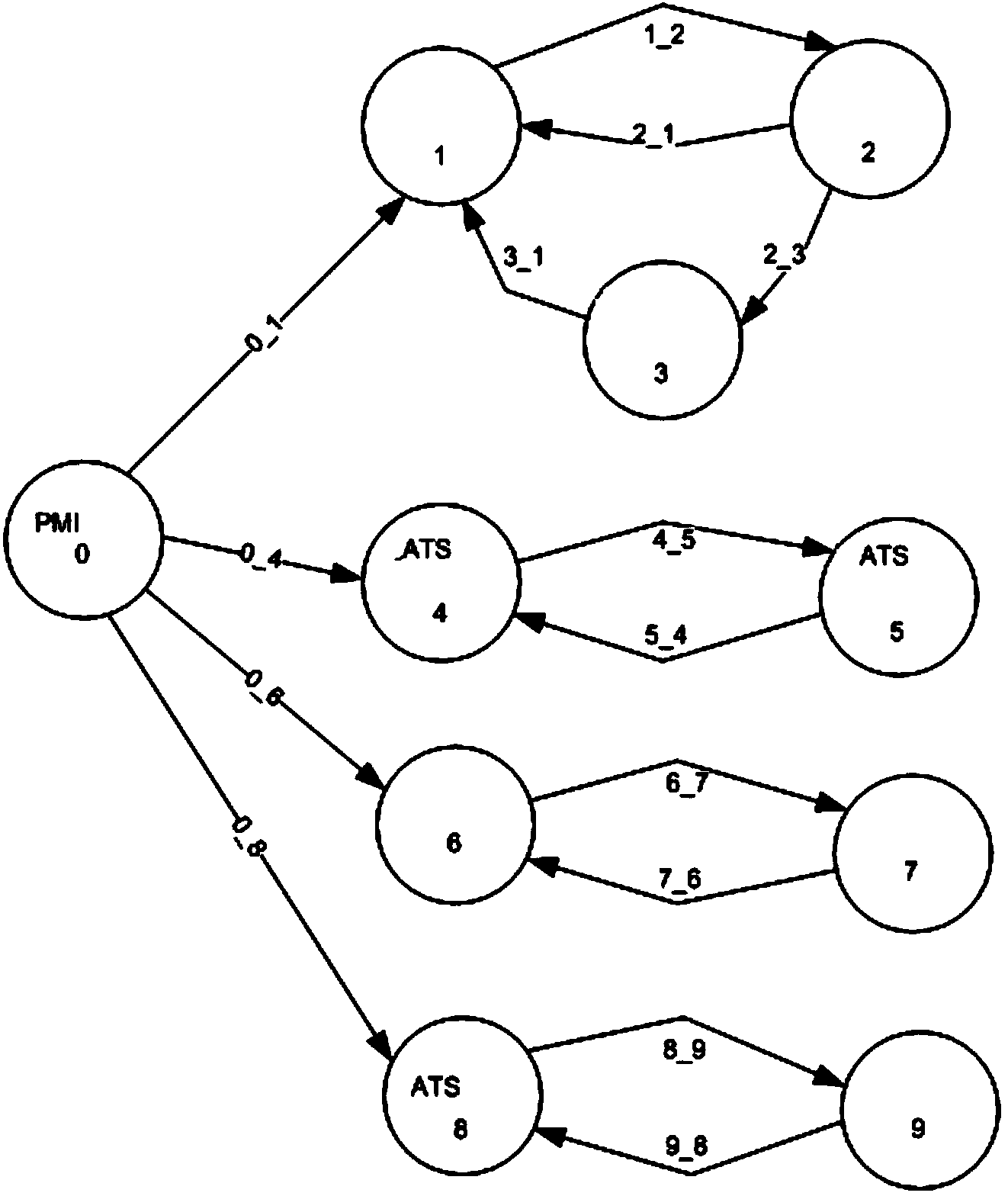

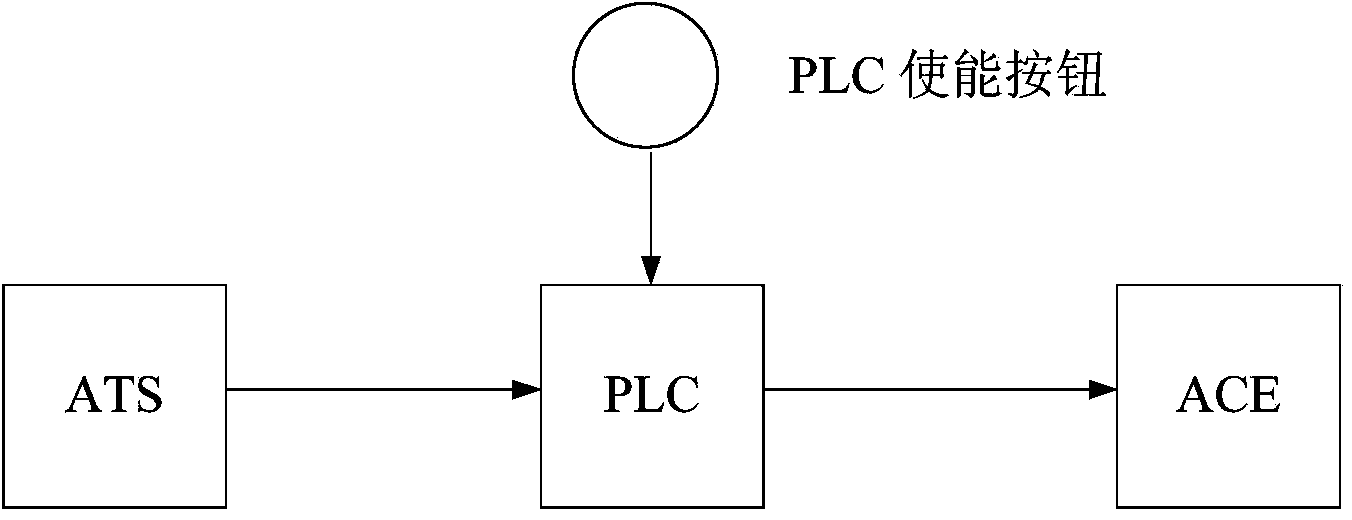

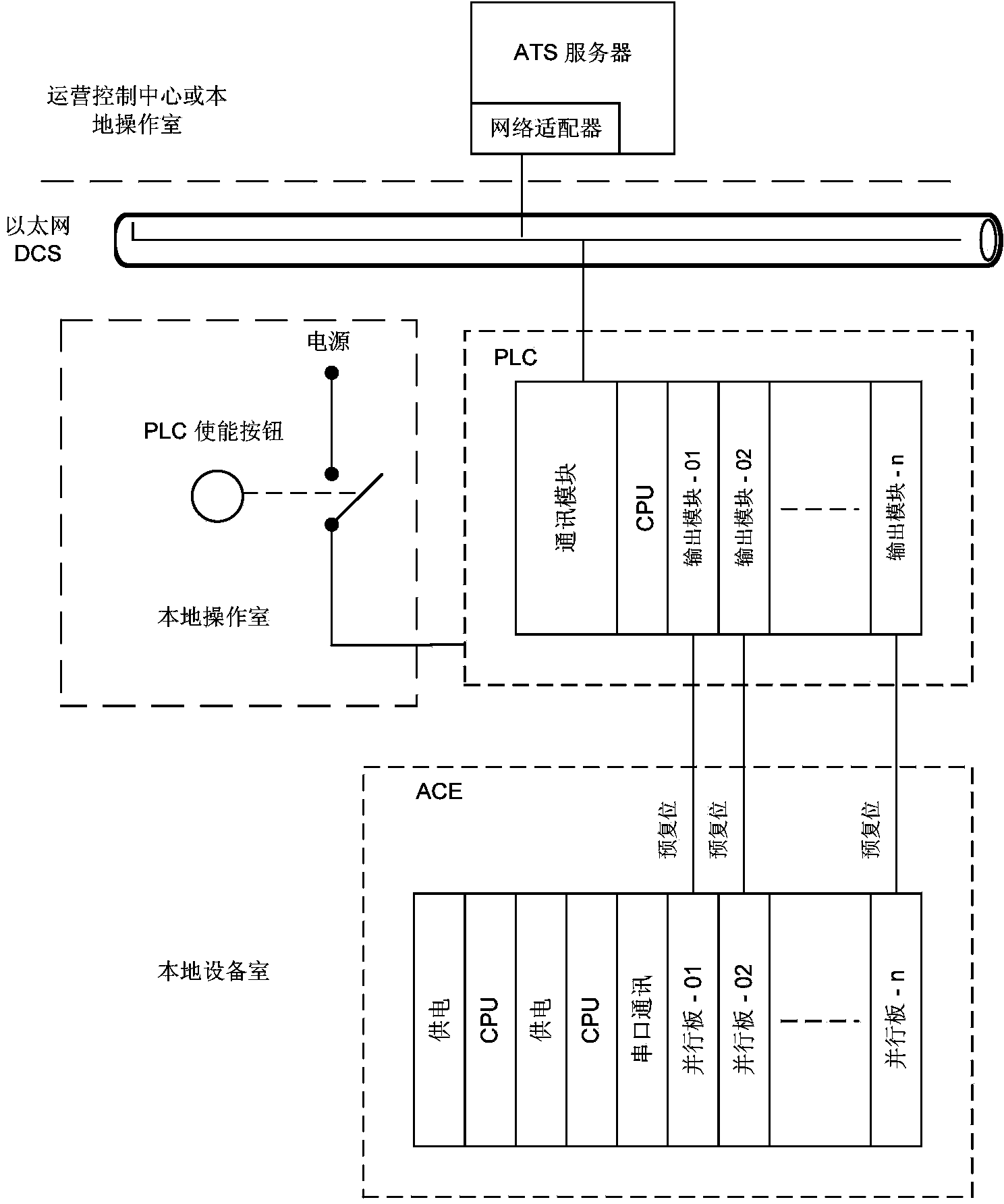

[0039] see image 3 , the remote shaft recording pre-reset system of the present invention includes ATS server, PLC, ACE, PMI and relay group, wherein:

[0040] The ATS server is connected to PMI and PLC respectively through Ethernet; PLC is connected to ACE; each relay coil in the relay group is respectively connected to PMI, and each normally open contact is connected in series between the power supply and PLC.

[0041] The ATS server is used to output the remote axle counting pre-reset command; the PMI receives the remote axle counting pre-reset command, drives each relay in the relay group to keep the high position to connect the power supply and PLC, and returns;

[0042] According to the recovery signal of PMI, the ATS server sends the remote axle counting pre-reset command to the PLC after knowing that each relay in the relay group is in a high state;

[0043] PLC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com