A waste copper pipe extrusion deformation conveying device

A technology of extrusion deformation and transportation device, which is applied in the field of waste copper pipe extrusion deformation transportation device, can solve the problems of low efficiency, small carrying capacity of a single vehicle, puncture, etc., and achieve the goal of reducing the occupied volume and increasing the single loading capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

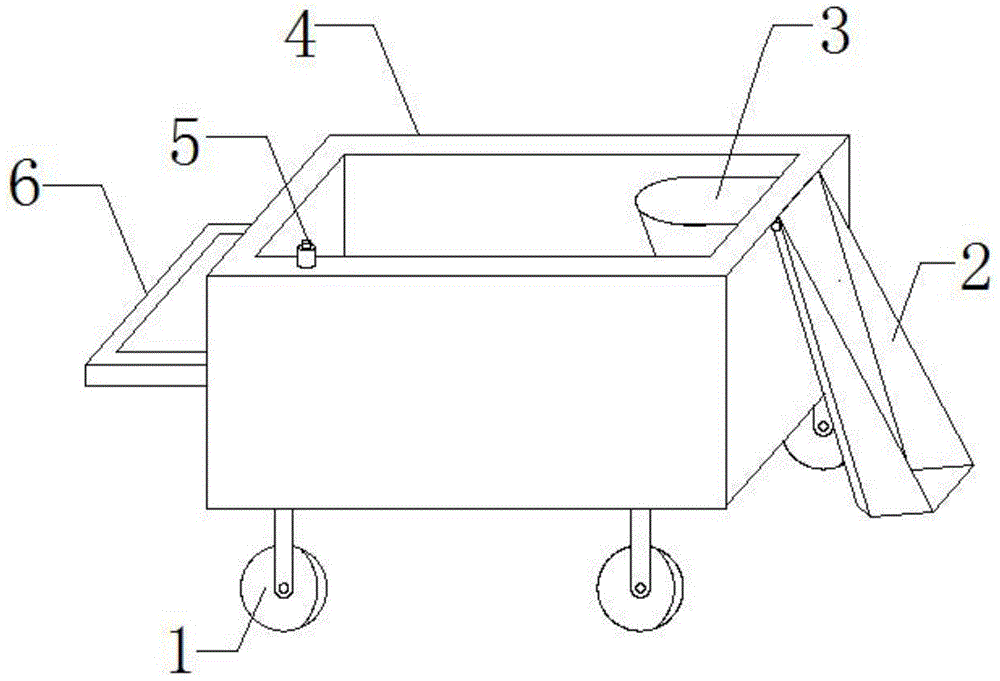

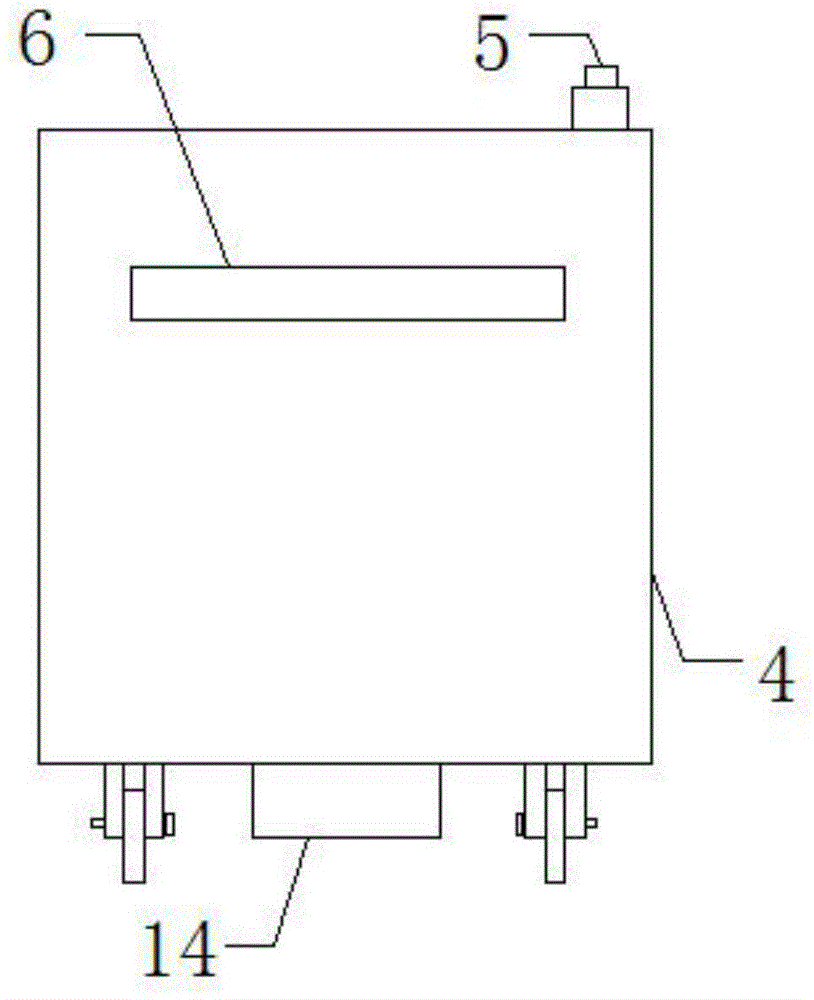

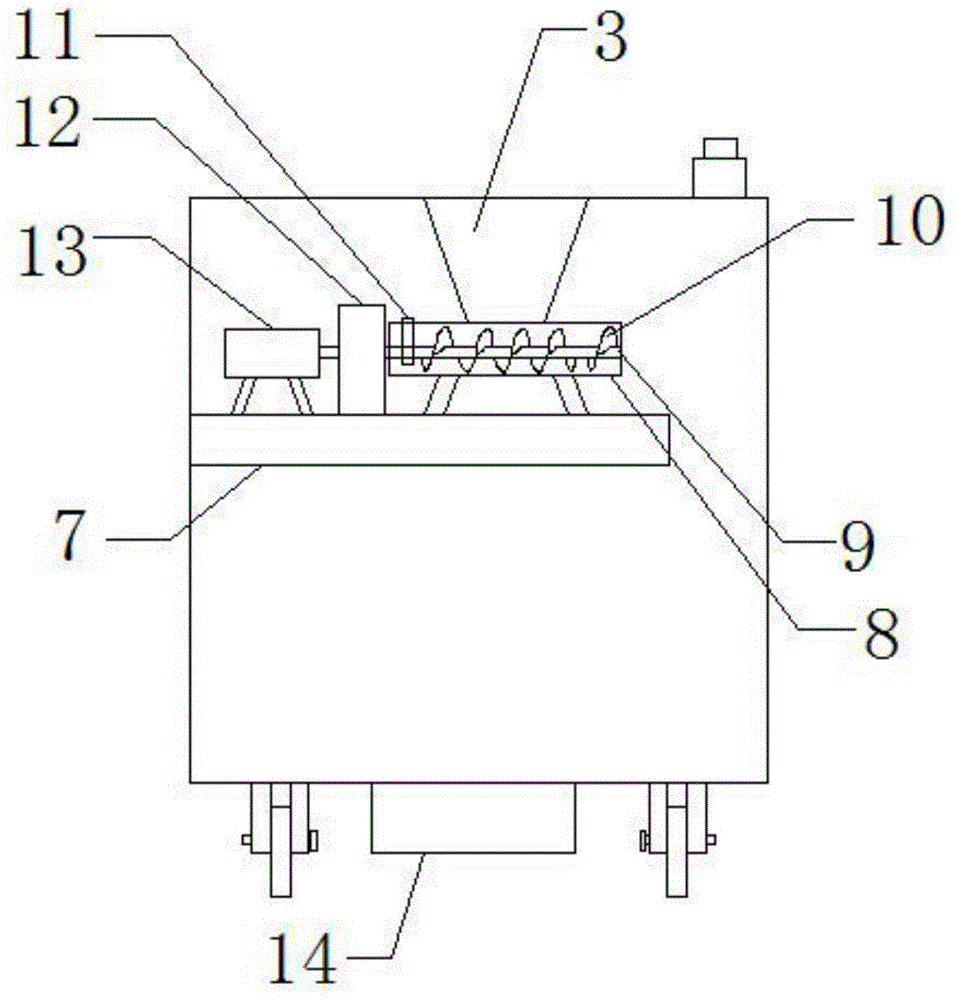

[0019] Embodiment 1: a kind of scrap copper pipe extrusion deformation delivery device, its structure is as Figure 1-3 Shown: includes a trolley 1, the trolley 1 has a compartment 4, a support plate 7 is arranged inside the compartment 4, and a motor 13, a planetary reducer 12 and an extruder are sequentially installed on the support plate 7, and the extruder includes a shell 8. The top of the casing 8 is connected to the feed hopper 3, and the casing 8 is provided with a transmission shaft 9 and a suspension bearing 11, and the transmission shaft 9 runs through the inner ring of the suspension bearing 11; the transmission shaft 9 is provided with a screw auger 10, and the transmission The left end of the shaft 9 is connected to the output end of the planetary reducer 12, and the output shaft of the motor 13 is connected to the input end of the planetary reducer 12; Feeding mechanism.

[0020] The feeding mechanism is a bucket 2 which is hinged to the outer wall of the troll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com