Motor vehicle axle with auxiliary frame

A technology for assisting vehicle frames and motor vehicles, applied in vehicle components, substructures, transportation and packaging, etc., can solve problems such as rising manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The same reference numerals are used in the figures for identical or similar components, even when repeated descriptions are omitted for reasons of simplification.

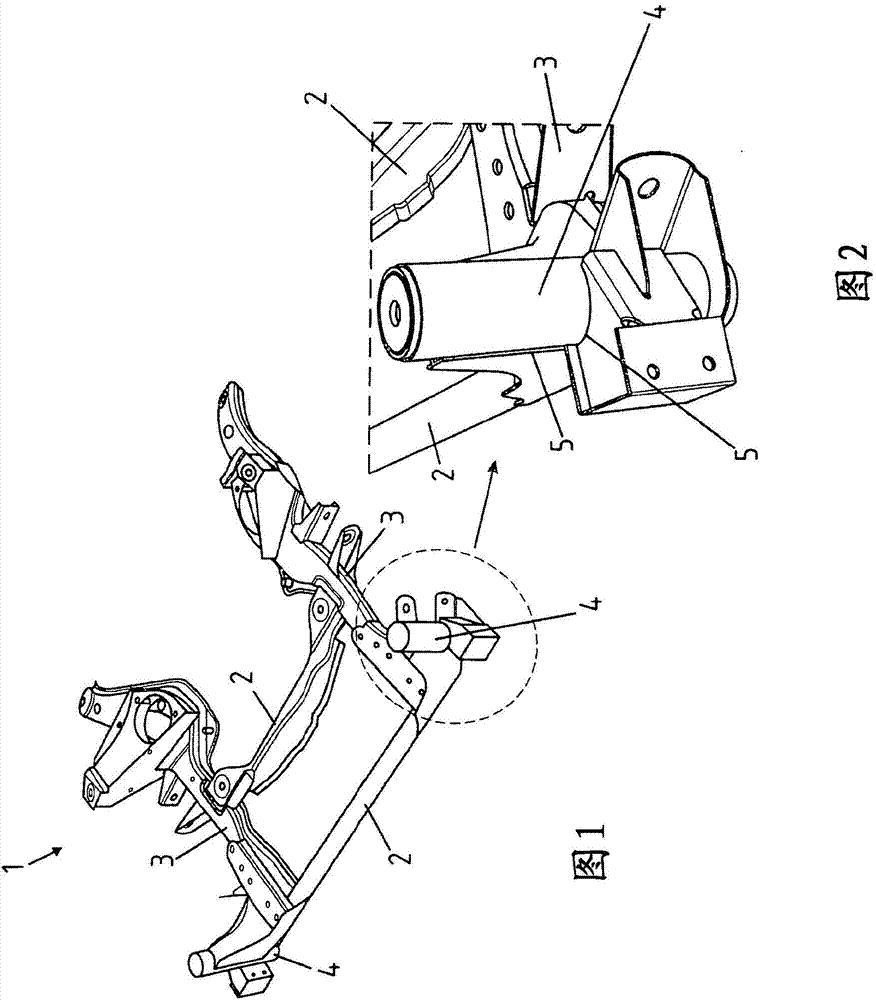

[0020] figure 1 Shown is a perspective view of an auxiliary frame 1 according to the invention. The auxiliary frame 1 has two transversely extending transverse beams 2 , wherein a frame element 3 is coupled to each end of the transverse beams 2 . In turn, connecting sleeves 4 are fastened to the frame element 3 , by means of which the auxiliary frame 1 is coupled to a motor vehicle body, not further shown.

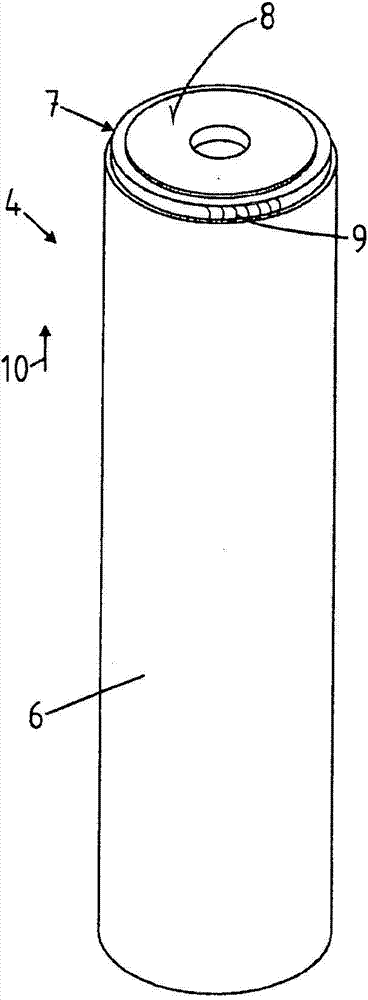

[0021] figure 2 A perspective detail view of such a connecting sleeve 4 is shown. The connecting sleeve 4 is positively and materially fixed in the frame element 3 by means of a weld seam 5 .

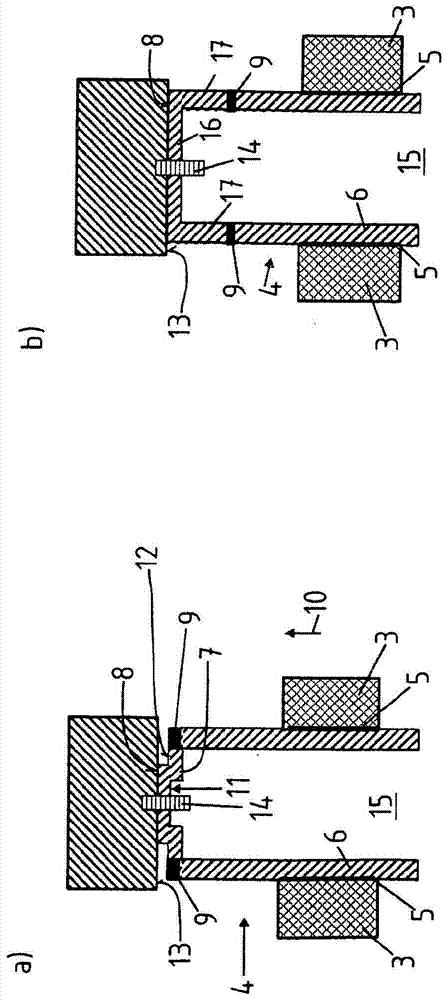

[0022] image 3 Shown is a perspective detail view of a connecting sleeve 4 according to the invention. For this purpose, the connecting sleeve has a sleeve body 6 and a receiving plate 7 which in turn ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com