Toolbox rotation direction position restriction structure

A technology of rotation direction and tool box, which is applied in the direction of spare tire arrangement, transportation and packaging, vehicle parts, etc., and can solve the problems of destroying the tool box, damaging the inner peripheral surface of the wheel part, and generating noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the present invention will be described in detail based on embodiments of the drawings.

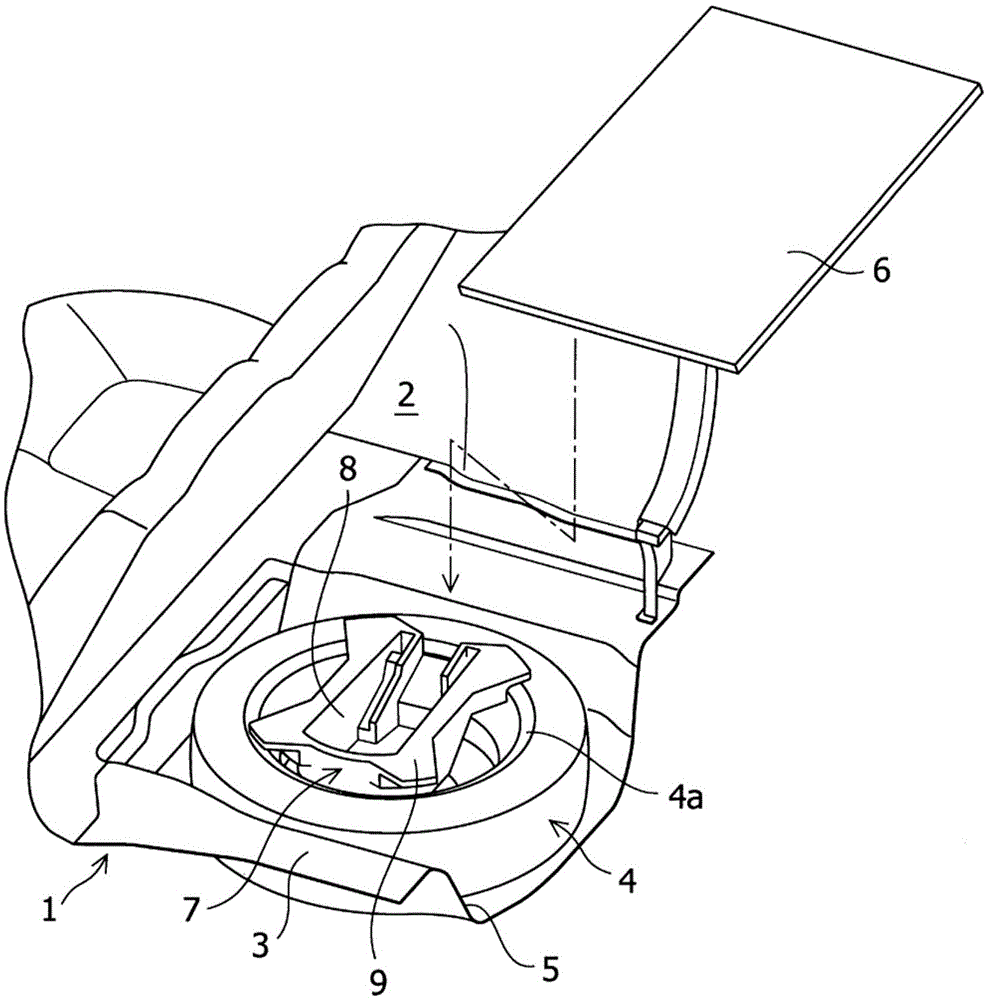

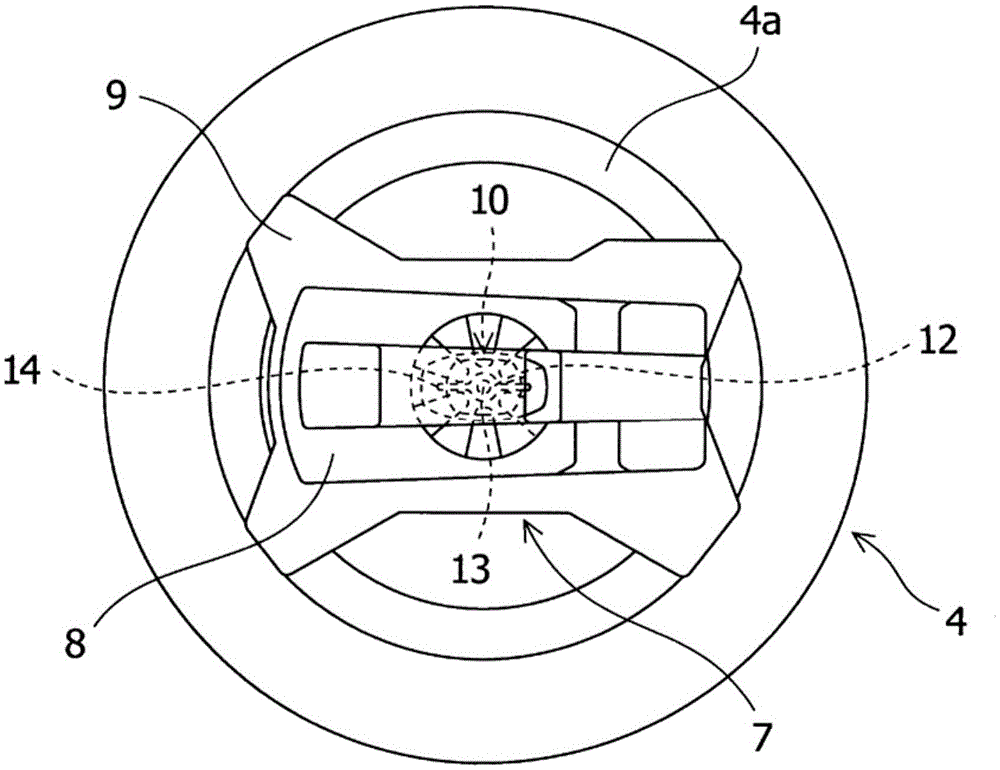

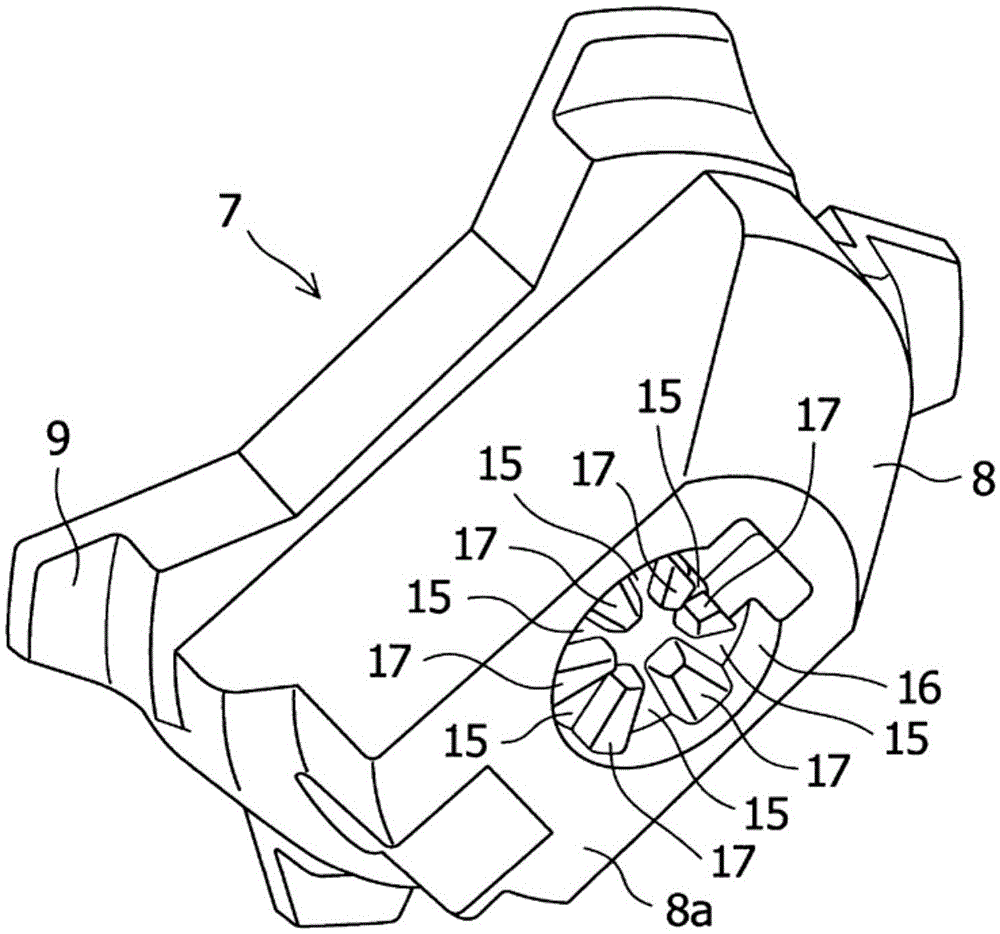

[0032] Figure 1 to Figure 7 It is a figure which shows the rotation direction position control structure of the toolbox which concerns on embodiment of this invention.

[0033] Such as figure 1 As shown, in the rear part 1 of the vehicle to which the rotation direction position limiting structure of the toolbox according to the embodiment of the present invention is applied, a trunk 2 for loading luggage is provided, and the floor 3 of the trunk 2 is formed in a downwardly concave manner. In the storage recess 5 for storing the spare tire 4 . In addition, a flat luggage board 6 constituting the floor surface is provided on the floor 3 in the luggage room 2 , and the upper opening of the storage recess 5 is covered with the luggage board 6 .

[0034] The spare tire 4 is installed inside the storage recess 5 in a state of lying down, and the wheel portion 4 a is fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com