Self-balancing liquid crystal substrate lifting and turning mechanism

A liquid crystal substrate and flipping mechanism technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of liquid crystal substrate crushing and damage, and achieve the effect of reducing production costs and reducing direct pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

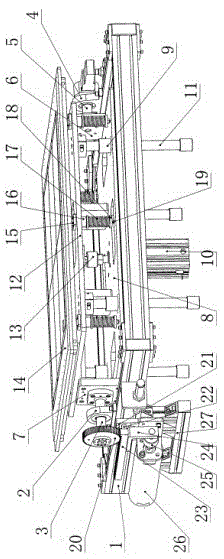

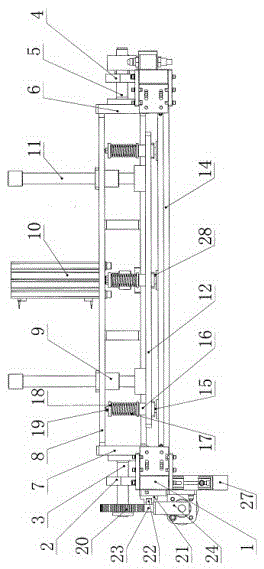

[0011] The present invention is described in detail below in conjunction with accompanying drawing:

[0012] A self-balancing liquid crystal substrate lifting and turning mechanism, comprising a rectangular support frame 1, a left support bearing 2 is arranged on the left frame of the rectangular support frame 1, a left support shaft 3 is arranged in the left support bearing 2, and a left support shaft 3 is arranged on the left support shaft 3 The left end of the left end is provided with turning gear 20, the right end of left support shaft 3 is provided with left support block 7, is provided with right support bearing 4 on the right frame of rectangular support frame 1, is provided with right support shaft 5 in right support bearing 4 , a right support block 6 is provided at the left end of the right support shaft 5, a flip base plate 8 is connected between the left support block 7 and the right support block 6, and four guide posts are arranged on the flip base plate 8 to pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com