Traction head

A technology of traction heads and arm sleeves, which is applied in the design and manufacture of traction heads, can solve the problems of unfavorable energy saving and environmental protection, breakage of traction heads, short service life, etc., and achieve the effects of improving service life, reducing friction and reducing hard damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in each drawing represent the same features or components, which can be applied in different embodiments.

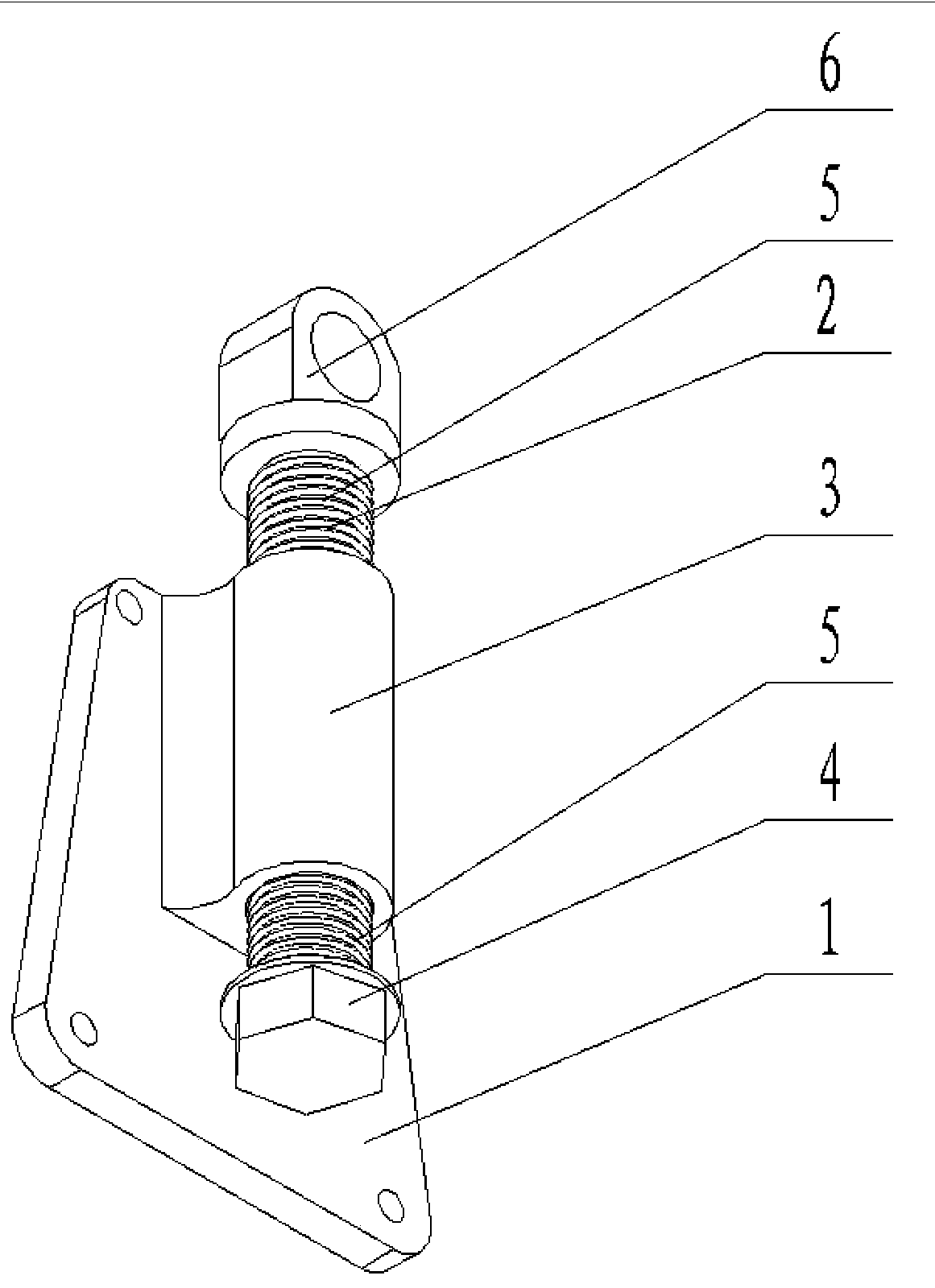

[0011] figure 1 Shown is the structural schematic diagram of this novel use.

[0012] The present invention comprises a traction base 1 , a stretch arm 2 and a stretch arm sleeve 3 . The four corners of the traction base 1 have holes and are fixed by bolts, and the stretch arm sleeve 3 is welded on the traction base 1 .

[0013] The tractor head is made of reinforced cast steel material, which is harder and wear-resistant, less pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com