Lifting device with quick locking

A kind of equipment and fast technology, applied in the direction of textiles and papermaking, paper machines, press parts, etc., can solve the problems of difficult control, increased difficulty, and impact of the adjustment process, and achieve the effect of simple reinstallation design and reduced investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

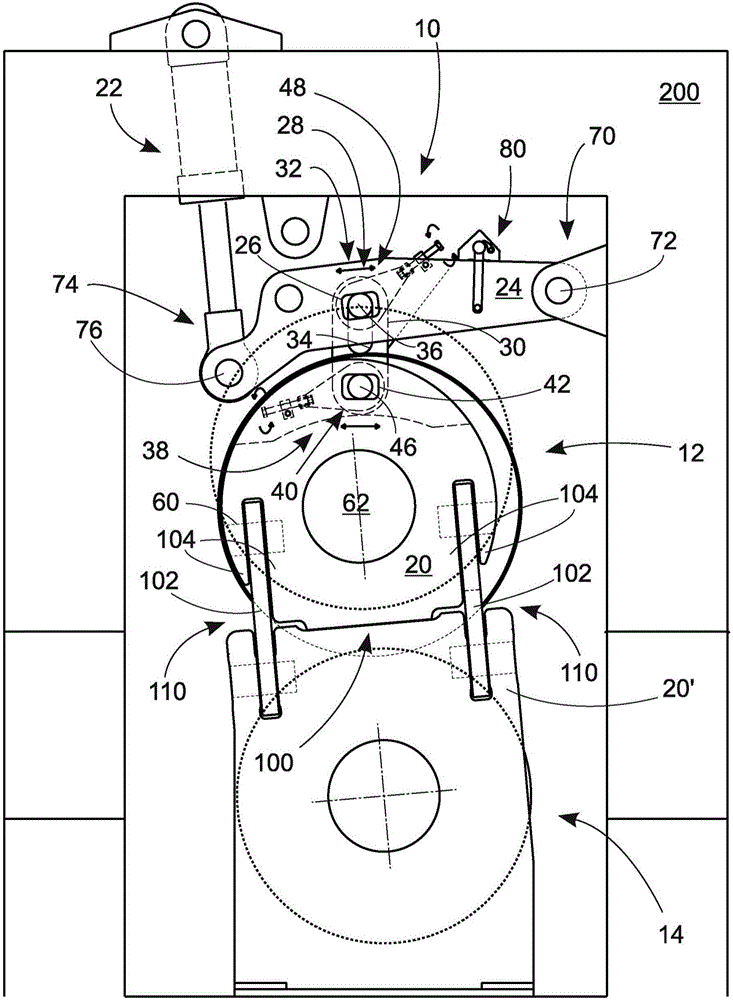

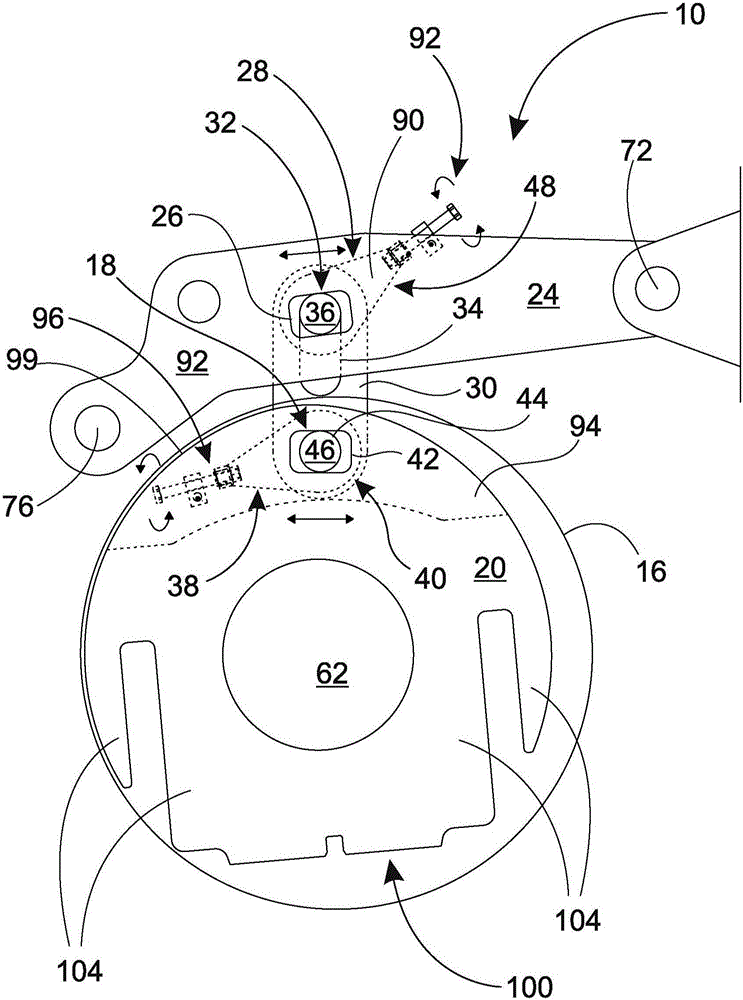

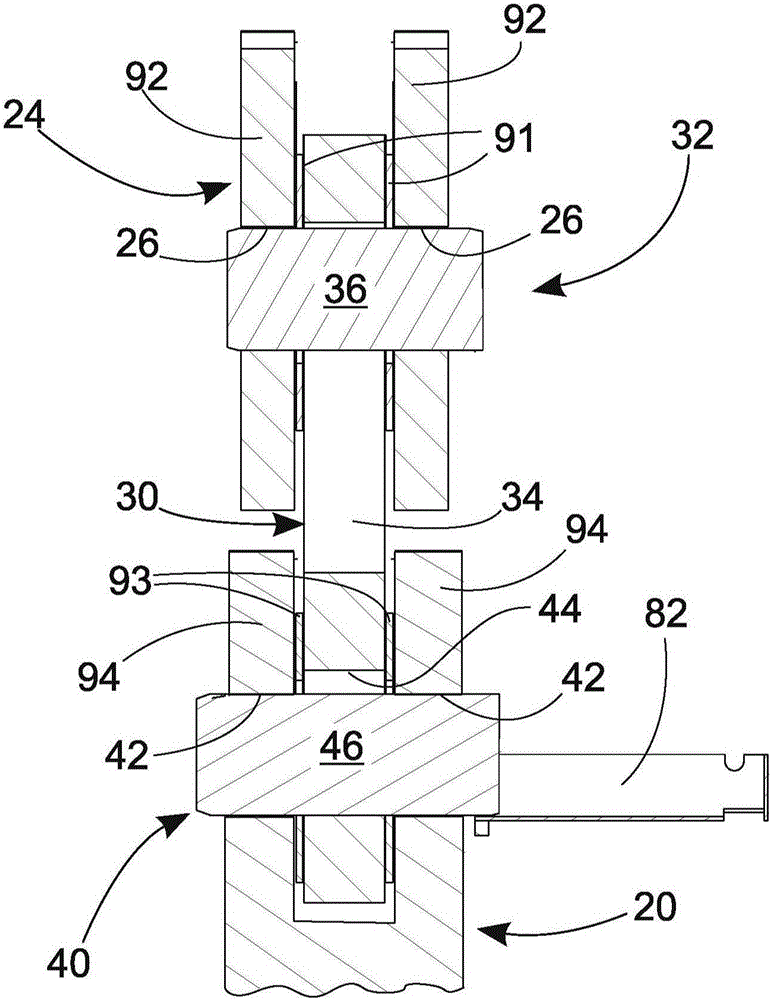

[0023] figure 1 A general view showing the connection between the shoe roll 12 and its counter roll 14 under the locked locking device 110 . In the locked position, the bearing housing 20 of the shoe roll 12 and the bearing housing 20' of the counter roll 14 overlap with the contact surface 100, which is an addition to the bearing housings 20 and 20' of the locking device 110 104 also coincides with the connecting arm 102 between the two additional parts 104 . In order to be able to remove the band jacket of the shoe roller 12 from the roller for replacement, the locking device 110 must be released and the shoe roller 12 must be lifted into the air. Strip sheath 16 in figure 2 shown in . Returning the shoe roller 12 to its position on the counterroll 14 with the lifting device according to the invention is not practically possible or at least extremely difficult and time-consuming to align the contact surface 100 with conventional lifting tools.

[0024] figure 1 A lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com