Special reinforcement system for gear-shaped pilaster groove formwork

A pilaster-shaped, gear-shaped technology is applied in the field of pilaster formwork reinforcement system, which can solve the problems of inconvenient disassembly and assembly, poor rigidity of pilaster formwork, inability to adapt to irregular structure formwork installation, etc., and achieves convenient installation and disassembly. The effect of being conducive to demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

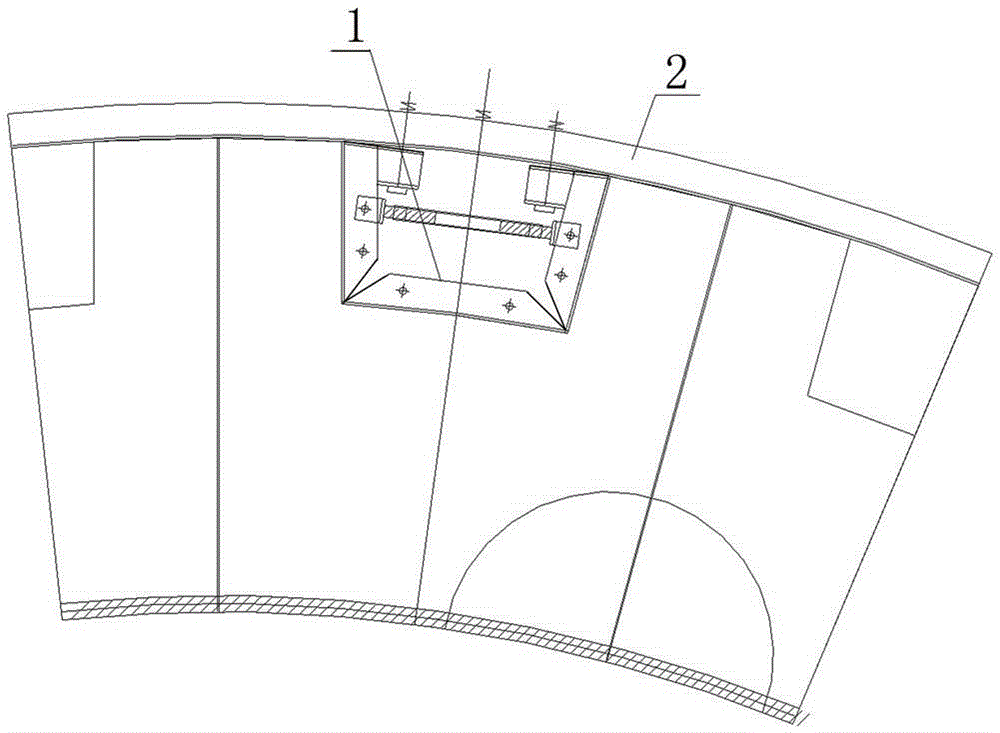

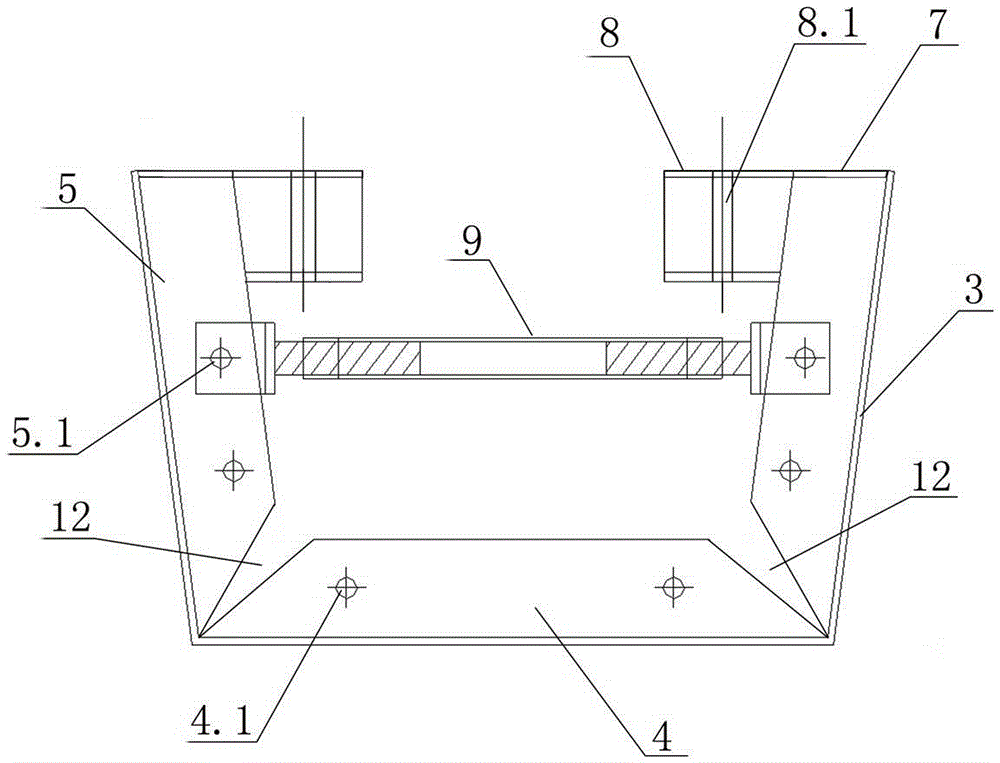

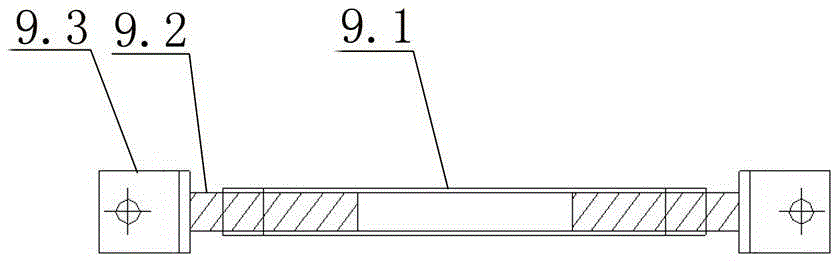

[0034] Examples see Figure 1-6 As shown, this special reinforcement system for gear-shaped pilaster groove formwork includes panels, back corrugations, vertical ribs 7 of full-length steel slats, locks 8, adjusting screw 9 and wooden square supports 10. The panel is a concave panel 3 formed by bending a steel plate. The back flute includes a main back flute 4 transversely welded on the inner wall of the concave panel 3 and side back flutes 5 on the left and right sides of the main back flute. There is a gap for adjusting the angle of the template itself at the adjacent places of the side back flute 5 . Concave panel 3 two ends places are respectively welded with a long steel bar vertical rib 7, the full length steel bar vertical rib 7 inner surface is welded with the side back corrugated 5, and the full length steel bar vertical rib 7 outer surface can be bonded with rubber strip. The lockset 8 is welded vertically at intervals on the vertical ribs 7 of the long steel slats...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com