Round belt bonding machine

A bonding machine, round belt technology, applied in mechanical equipment, belt fasteners, belts/chains/gears, etc., can solve the problems of increased economic expenditure, slow processing speed, complex production equipment, etc., to meet the needs of rapid development , Reduce the cost of sales, the effect of fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

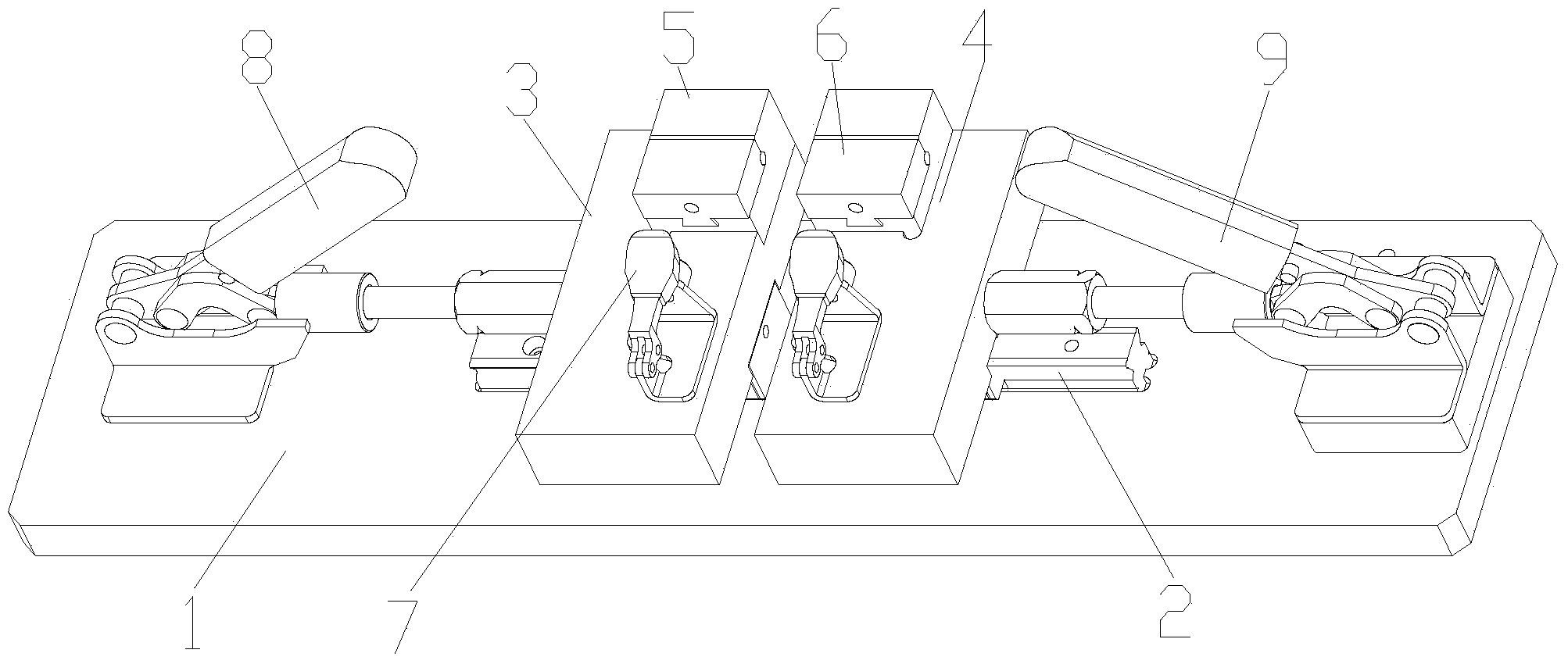

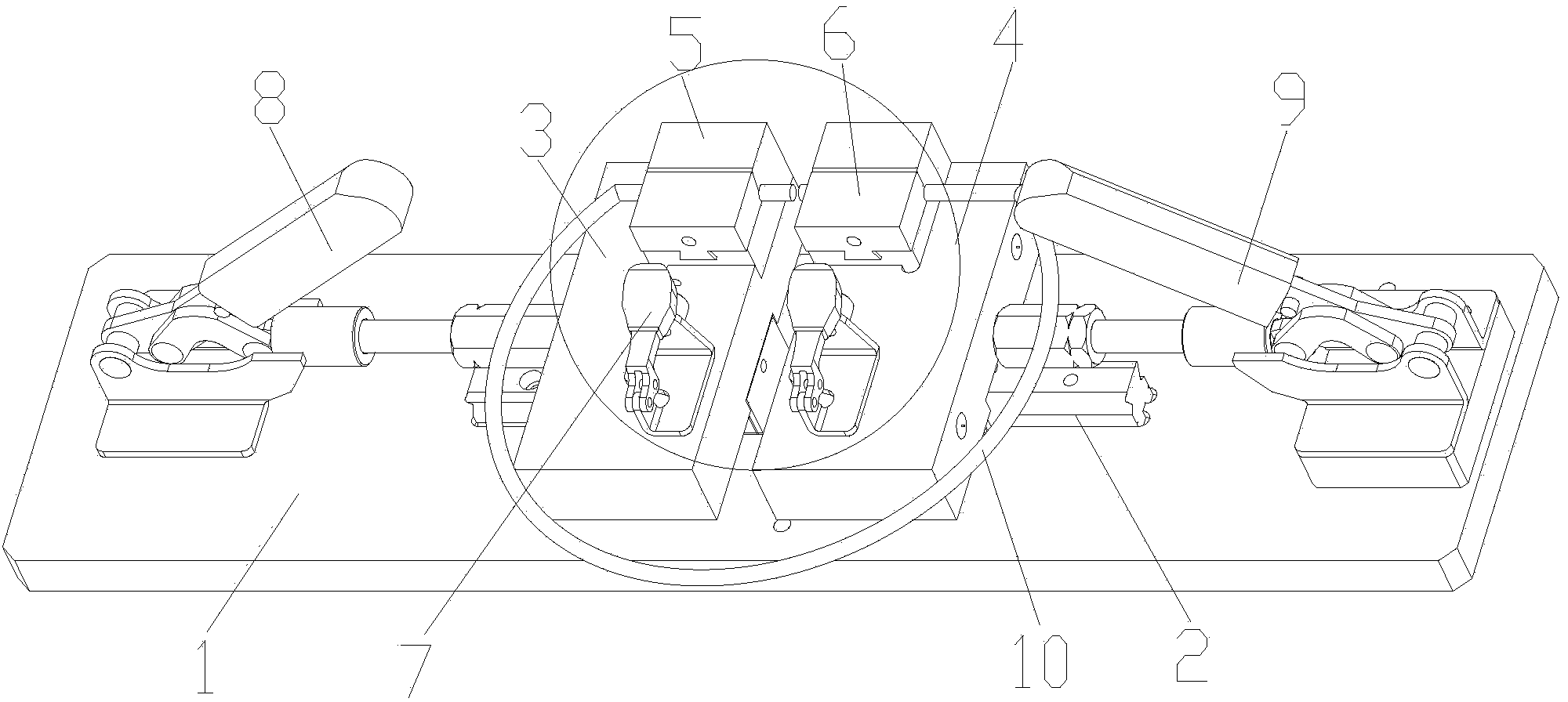

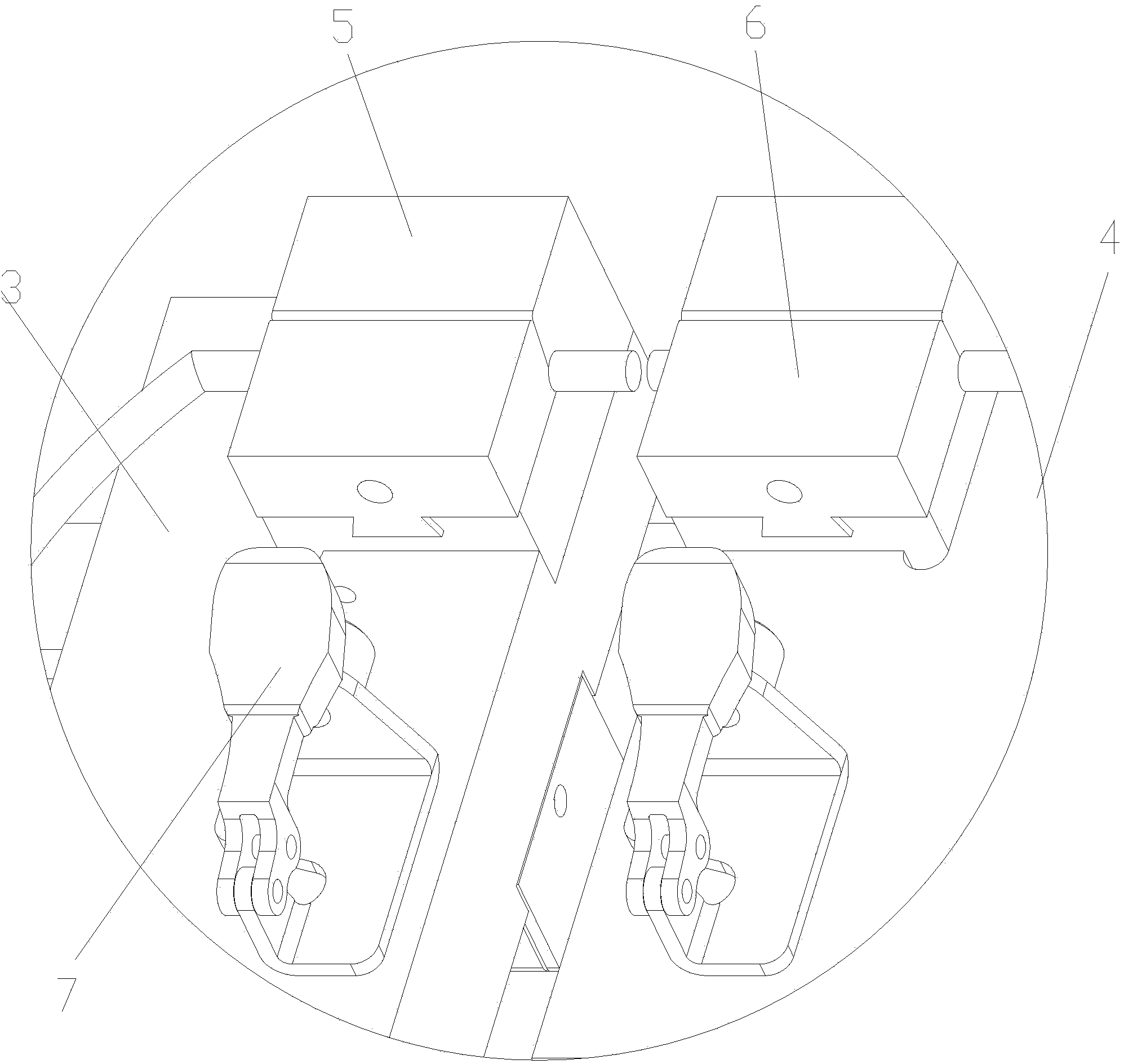

[0012] The present invention will be described below with reference to the drawings.

[0013] As attached Figure 1-3 The round belt bonding machine according to the present invention shown includes a base frame 1, a moving guide rail 2, a left sliding block 3, a right sliding block 4, a clamping fixing block 5, a clamping positioning block 6, a first manual The chuck 7, the left hand chuck 8 and the right hand chuck 9; the bottom frame 1 is provided with a moving rail 2; the moving rail 2 is provided with a left sliding block 3 and a right sliding block 4 that slide relatively; The left sliding block 3 and the right sliding block 4 are respectively provided with a clamping and fixing block 5; the clamping and fixing block 5 is provided with a first manual chuck 7 on one longitudinal side; a pressing rod of the first manual chuck 7 There is a clamping and positioning block 6; the clamping and fixing block 5 and the clamping and positioning block 6 are both provided with circular...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap