Nozzle, hard pipe joint structure, and device and method for nipple processing

A joint structure, hard pipe technology, applied in the direction of pipe/pipe joint/pipe fitting, manufacturing tool, sleeve/socket connection, etc., can solve the problem of difficult application of hydraulic system, etc., and achieve the effect of high pressure level and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

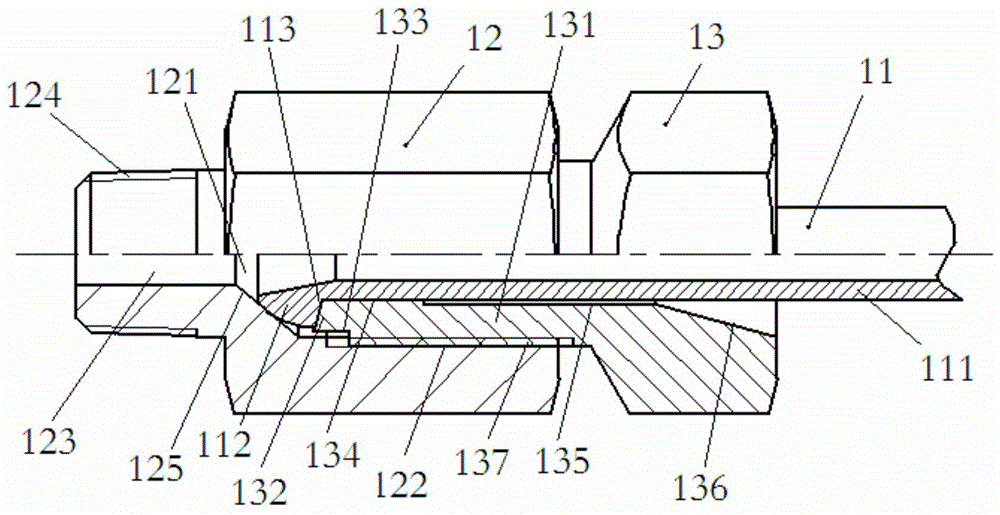

[0035] Please refer to figure 1 , the first embodiment provides a hard pipe joint structure, which includes a connecting pipe 11 , a joint body 12 and a connecting piece 13 .

[0036] The connecting pipe 11 has a through hole, which can be optionally annealed and treated with a low carbon steel seamless pipe. The connecting pipe 11 includes a pipe body 111 and a spherical head body 112 coupled with the pipe body 111 . The diameter of the bottom wall 113 of the head body 112 is larger than the diameter of the pipe body 111 , so that the head body 112 protrudes laterally from the outer wall of the pipe body 111 to form a root angle. The root angle can be any angle, and here are three examples, such as 90°, 115° or 135°, among which 115° and 135° are more conducive to stress, and avoid the problem of root cracks after multiple uses of the head body 112 .

[0037] The joint body 112 has a flow hole, and the flow hole is divided into a first hole section 121 , a second hole secti...

Embodiment 2

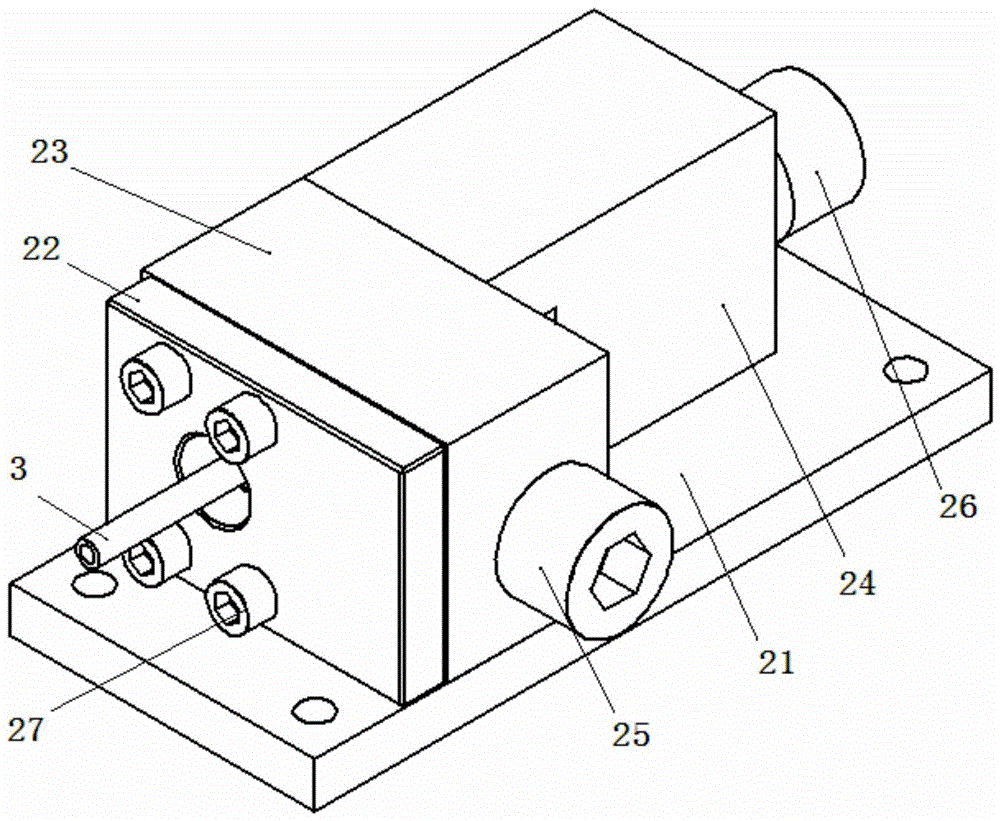

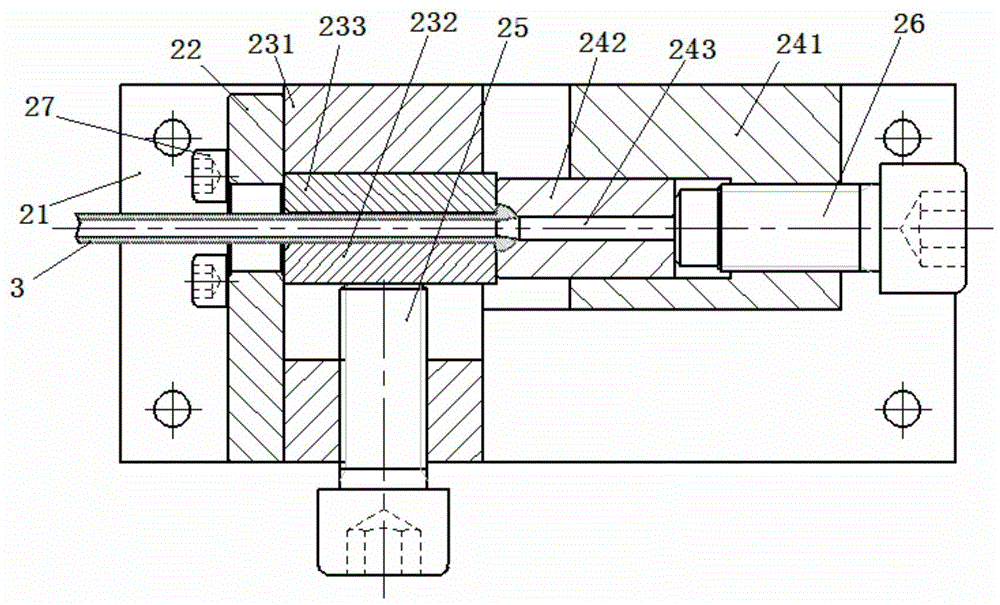

[0057] Please refer to figure 2 , the second embodiment provides a pipe connection processing device, which includes a base 21, an end cover plate 22, a pipe mold assembly 23, a ball mold assembly 24, a locking member 25 and a force member 26, which can be used to manufacture A nozzle shown and other nozzles having a spherical head.

[0058] Specifically, please refer to image 3 , the base 21 is used to make the whole device, which can be fixed on any stable position (such as a simple workbench), and the end cover plate 22 is then fixed on the base 21 .

[0059] In this embodiment, the pipe mold assembly 23 has a pipe mold body 231 , a first pipe mold 232 and a second pipe mold 233 . The nozzle mold body 231 is fixed on the base 21 and one end is against the end cover plate 22 , or it can be further locked on the end cover plate 22 by locking screws.

[0060] In addition, in addition to using the end cover plate 22 to limit the position of the pipe mold body 231, a limiti...

Embodiment 3

[0077] The third embodiment provides a processing method for the connecting pipe, which is to use a cold rolling forming process to roll the head body of the connecting pipe into a spherical shape.

[0078] The device shown in Embodiment 2 is a device designed according to the method shown in Embodiment 3. Of course, the device shown in Embodiment 2 is only an example of this method, and this method can also be realized by other devices in actual operation. method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com