Device and method for monitoring flame stability based on electrostatic sensor

A technology of electrostatic sensor and monitoring device, which is applied in the direction of safety device, combustion method, lighting and heating equipment of the combustion chamber, etc., and can solve the problems that cannot be widely used, and the optical probe is easy to be polluted by dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

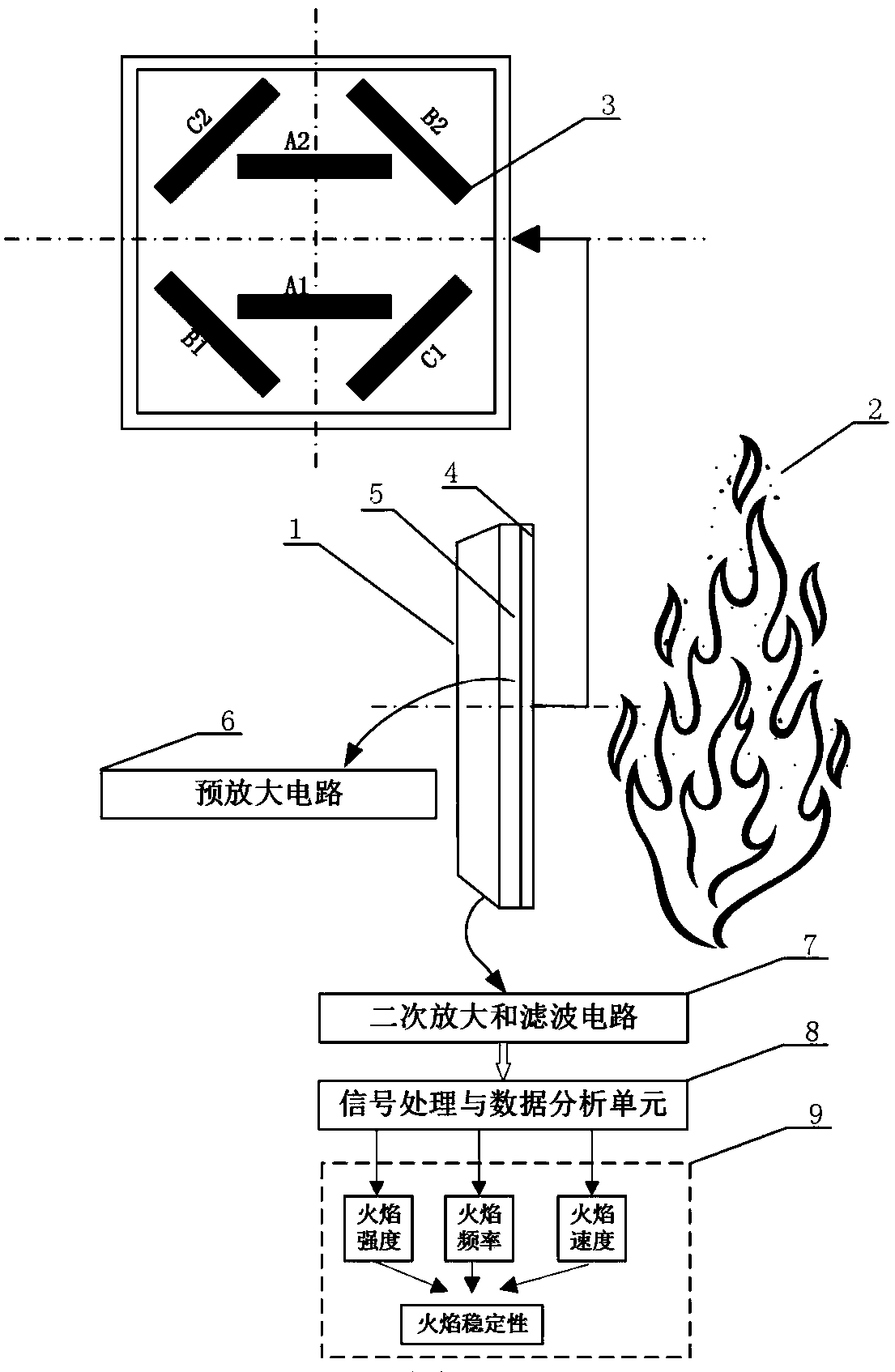

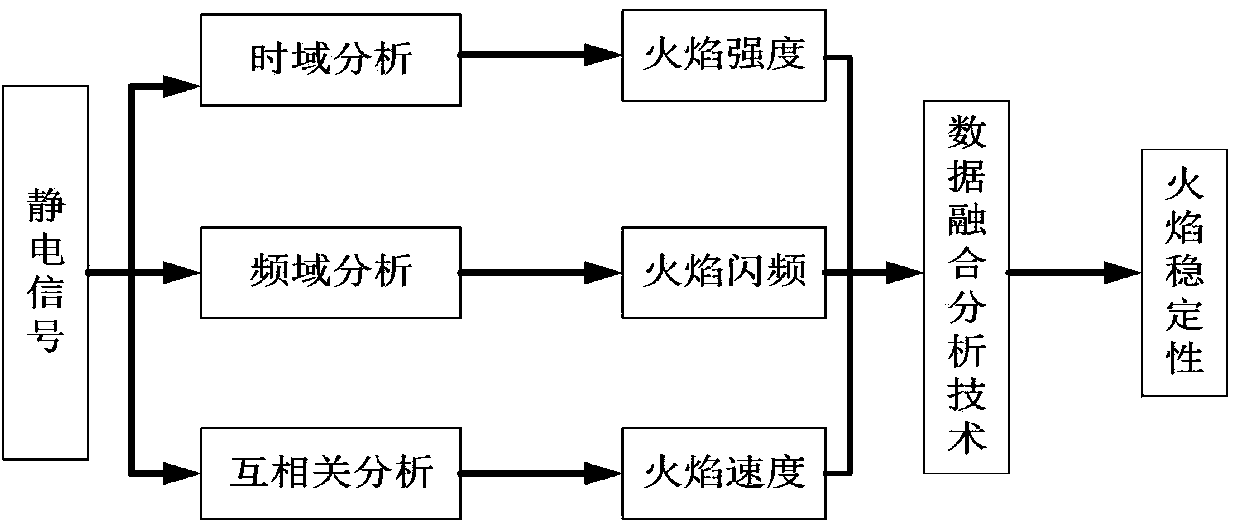

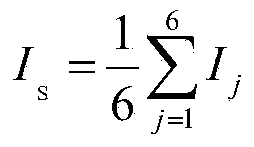

[0039] The present invention provides a flame stability monitoring device based on an electrostatic sensor, which is characterized in that the device includes an electrostatic sensor 1, a pre-amplification circuit 6, a secondary amplification and filtering circuit 7, a signal processing and data analysis unit 8, and a display unit 9. The electrostatic sensor 1 is three pairs of staggered strip electrostatic electrodes 3 (A1, A2, B1, B2, C1, C2) embedded in the end of the electrostatic sensor 1 close to the burner flame 2, sensing the position of the burner flame 2 Combustion characteristics information; each electrostatic electrode 3 is insulated from other parts by insulating material 4; in order to prevent signal interference, a shielding shell 5 is installed; in order to improve the signal-to-noise ratio, the output of each electrostatic electrode 3 is directly connected to the pre-amplification circuit 6; the output end of the pre-amplification circuit is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com