Ultra-high temperature cascade water source heat pump system

A water source heat pump, cascade technology, applied in the field of ultra-high temperature cascade water source heat pump system, can solve the problems of large heat transfer temperature difference in intermediate heat exchangers, energy efficiency decline, water temperature and heat limitation, etc., and achieve system energy efficiency improvement and reduction The effect of energy loss, heat transfer and temperature difference stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

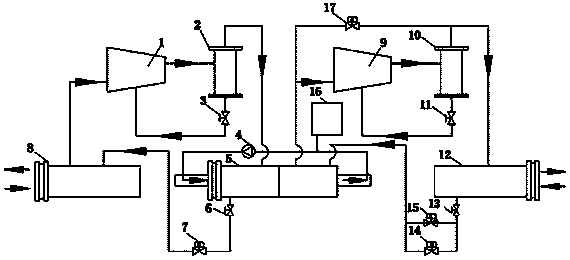

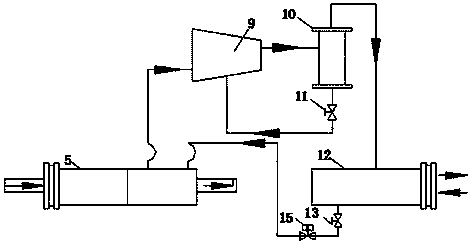

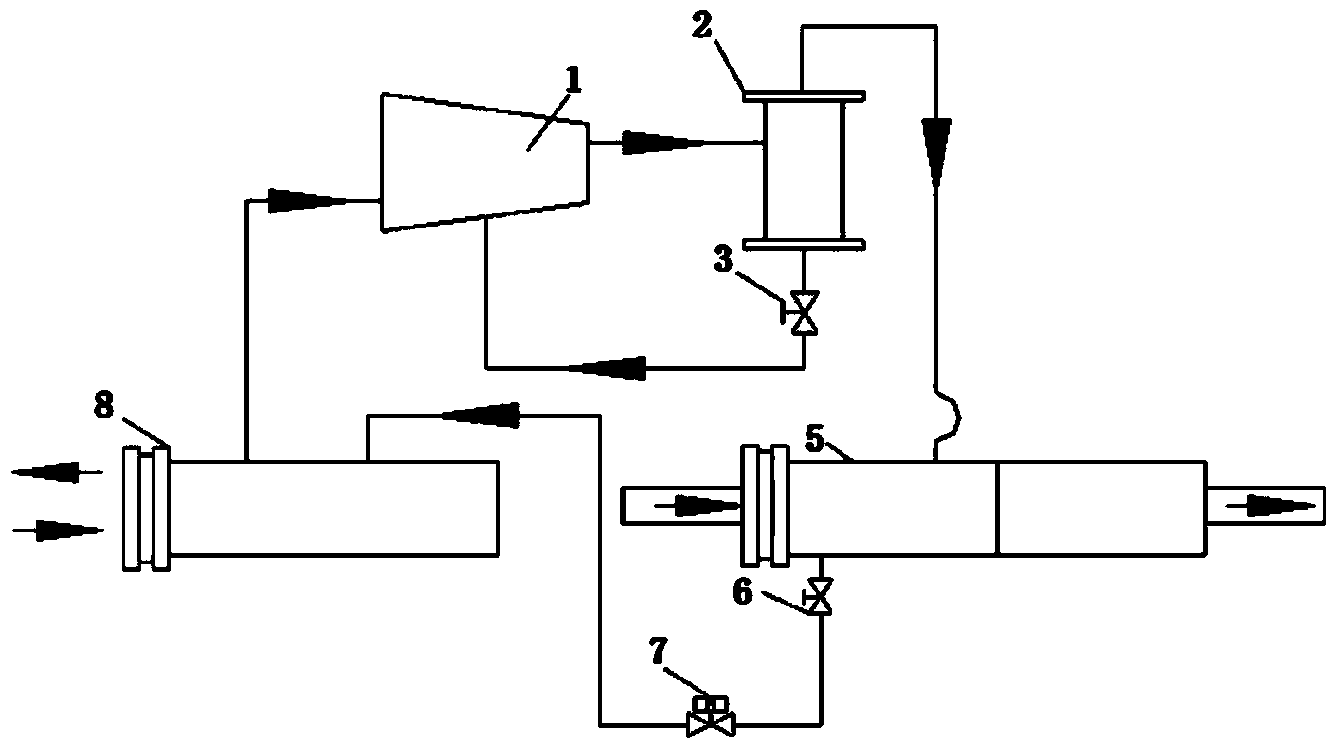

[0022] see Figure 1-Figure 3 , the ultra-high temperature cascade water source heat pump system in this embodiment includes an intermediate heat exchanger 5, a water pump 4, a water tank 16, a low-temperature unit and a high-temperature unit, and the low-temperature unit includes a first-stage compressor 1 and a first-stage oil separation unit. 2, the first stage oil circuit cut-off valve 3, the first stage liquid circuit stop valve 6, the first stage electronic expansion valve 7 and the evaporator 8, the high temperature unit includes the second stage compressor 9, the second stage oil separator 10. The second stage oil circuit stop valve 11, the condenser 12, the second stage liquid circuit stop valve 13, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com