Metal checking fixture spacer

A technology of gap pads and inspection tools, which is applied in the direction of measuring devices, instruments, etc., can solve problems such as irregular shape, influence of test results, unstable parts, etc., and achieve the effect of guaranteeing test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

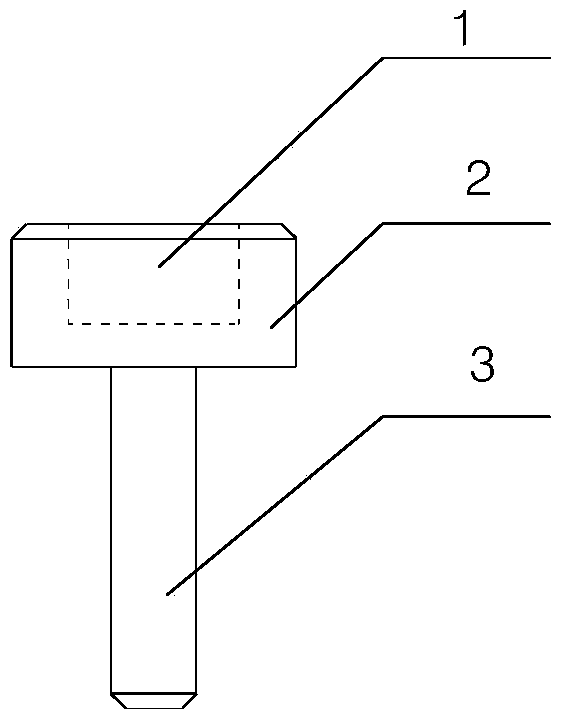

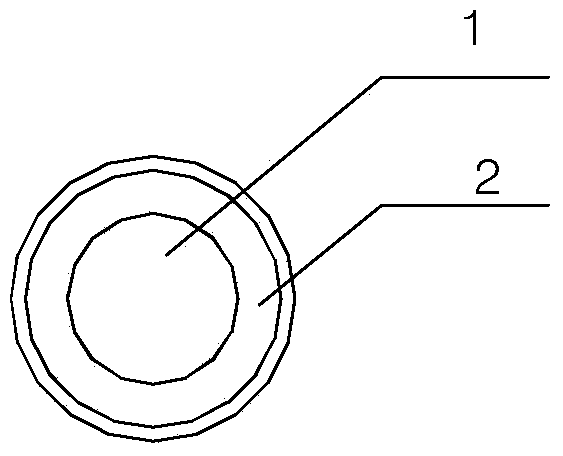

[0010] attached by figure 1 And attached figure 2 It can be seen that the present invention includes a cylindrical plug-in post 3 , and a backing panel 2 is provided on the top of the plug-in post 3 . A recessed hole 1 is formed in the center of the backing panel 2 downwardly. The diameter of the above-mentioned backing panel 2 is larger than that of the insertion column 3, and the bottom of the insertion column 3 and the top edge of the backing panel 2 are chamfered by technology.

[0011] The invention can be plugged and fixed on the inspection tool to support the part where the detected part and the inspection tool cannot be bonded, so as to play a stable and balanced role and make the detected data more accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com