Bearing simplifying method in finite element simulation analysis

A simulation analysis, finite element technology, applied to bearing simplification in finite element simulation analysis, finite element simulation analysis field, can solve problems such as low efficiency and large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

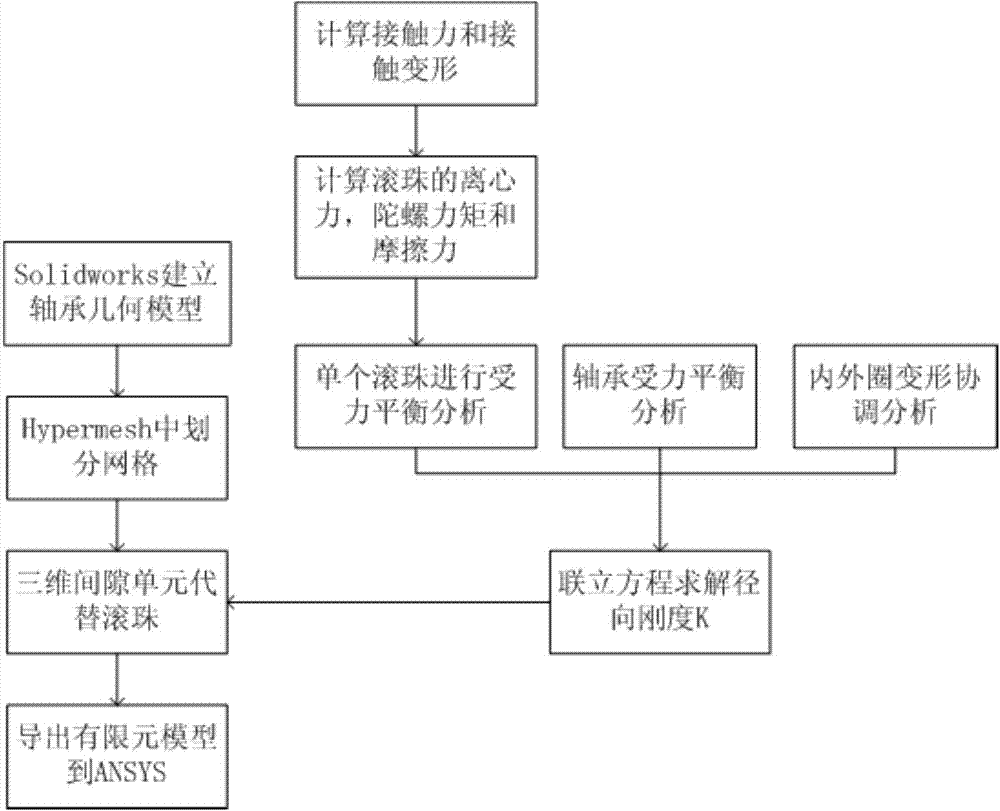

[0056] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

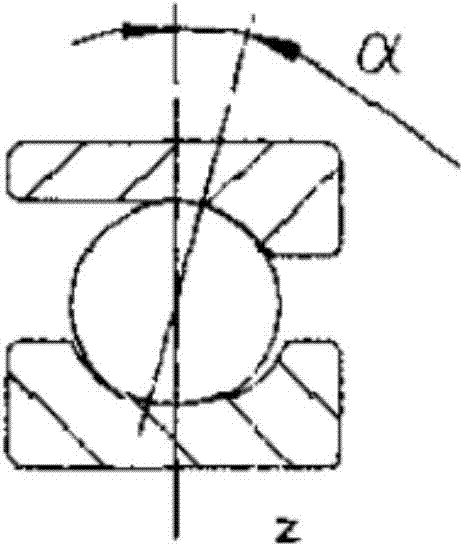

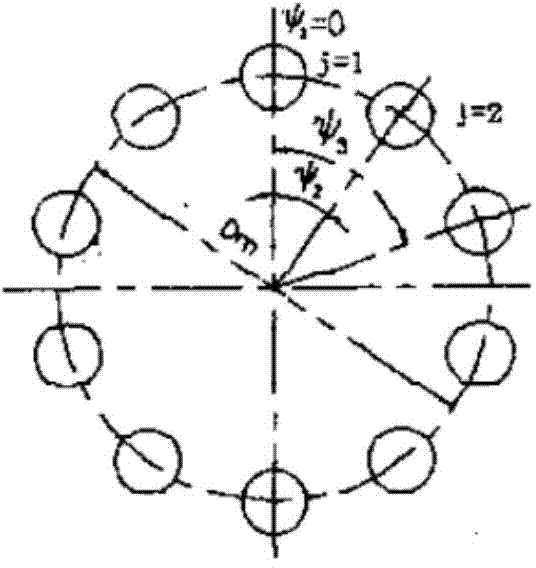

[0057] Take the angular contact bearing S7000 as an example. Draw the geometric model of the bearing in Solidworks such as figure 1 shown. Imported into Hypermesh, the inner and outer rings are meshed, such as figure 2 shown. Next follow the steps to calculate the radial stiffness of the bearing. The calculation parameters are shown in Table 1 below.

[0058] Table 1

[0059] parameters

value

Number of balls

13

Contact angle α(°)

15

Ball radius R j (mm)

2

Radius R of the outer ring raceway e (mm)

1.99

Radius R of the inner ring raceway i (mm)

1.99

bearing material

Bearing steel

Axial external load F a (N)

100

Rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com