Winding machine and storage device

A winding device, winding machine technology, applied in the direction of coil manufacturing, transportation and packaging, electrical components, etc., can solve the problems of coil thickness increase, transformer volume increase, electronic product volume increase, etc., to reduce thickness and solve volume increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

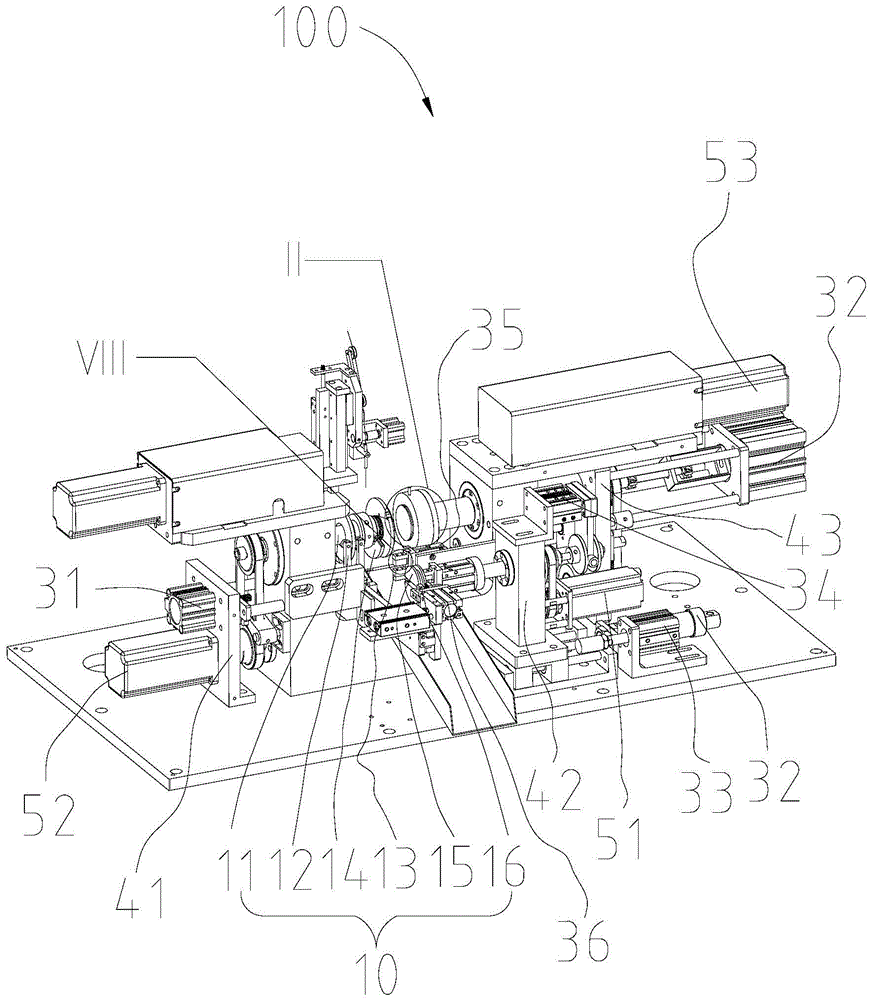

[0028] Please refer to figure 1 , the winding machine 100 provided by the present invention is used for winding N-layer coils, where N is an integer greater than or equal to 2.

[0029] In this embodiment, the N-layer coil is a 30-layer coil.

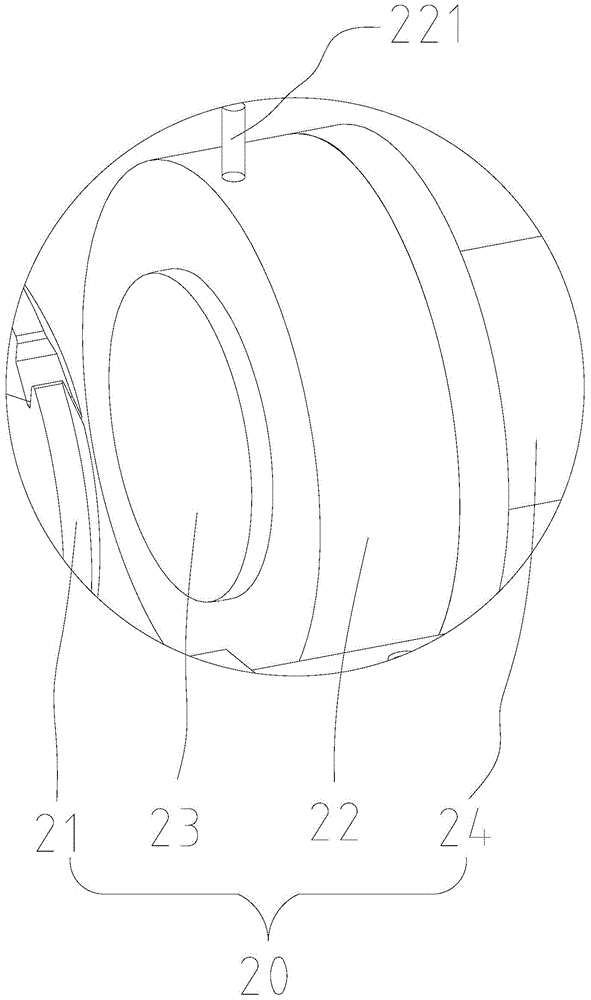

[0030] Please refer to Figure 1 to Figure 2 , the winding machine 100 includes a storage device 10 and a winding device 20 .

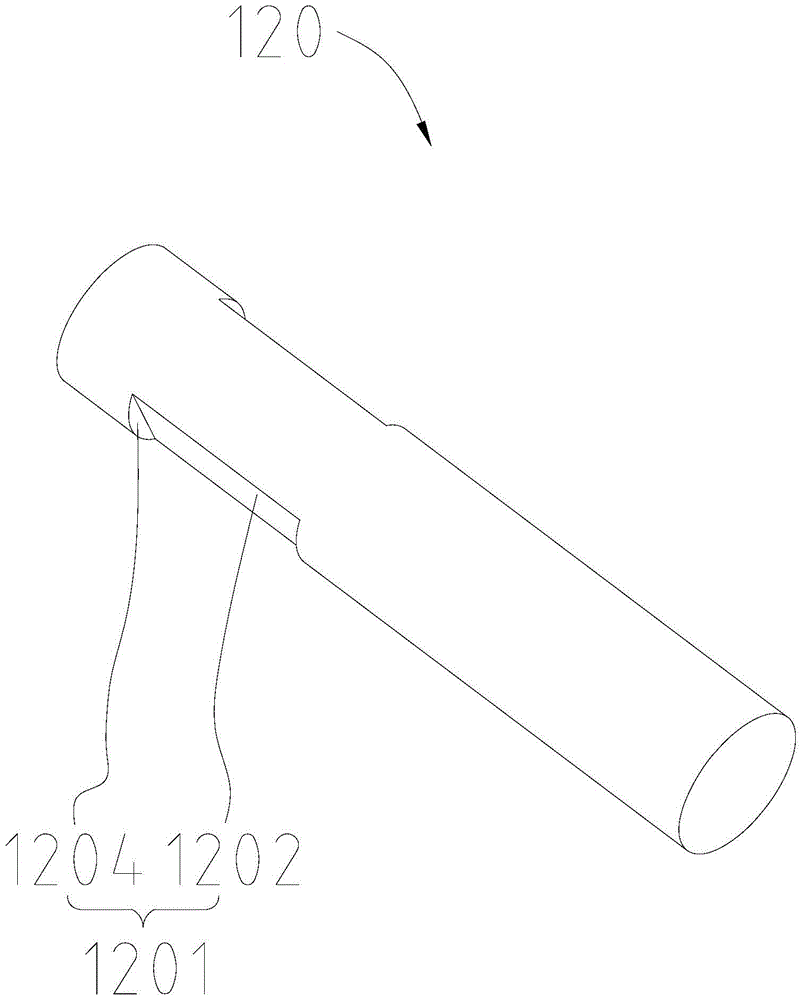

[0031] The wire storage device 10 is used to store the wire when the winding machine winds N-layer coils, and it includes a first main shaft 11, a first wire crimping device 12, a wire clamping device 16, a second wire crimping device 13, a first storage Wire part 14 and the second wire storage part 15, the first wire presser 12 is used to press the wire end of the wire rod, the first wire storage part 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com