Winding machine and winding method

A winding method and winding machine technology, applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc., can solve the problems of increasing the volume of transformers, increasing the thickness of coils, increasing the volume of electronic products, etc., to solve the problem of increasing volume , the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

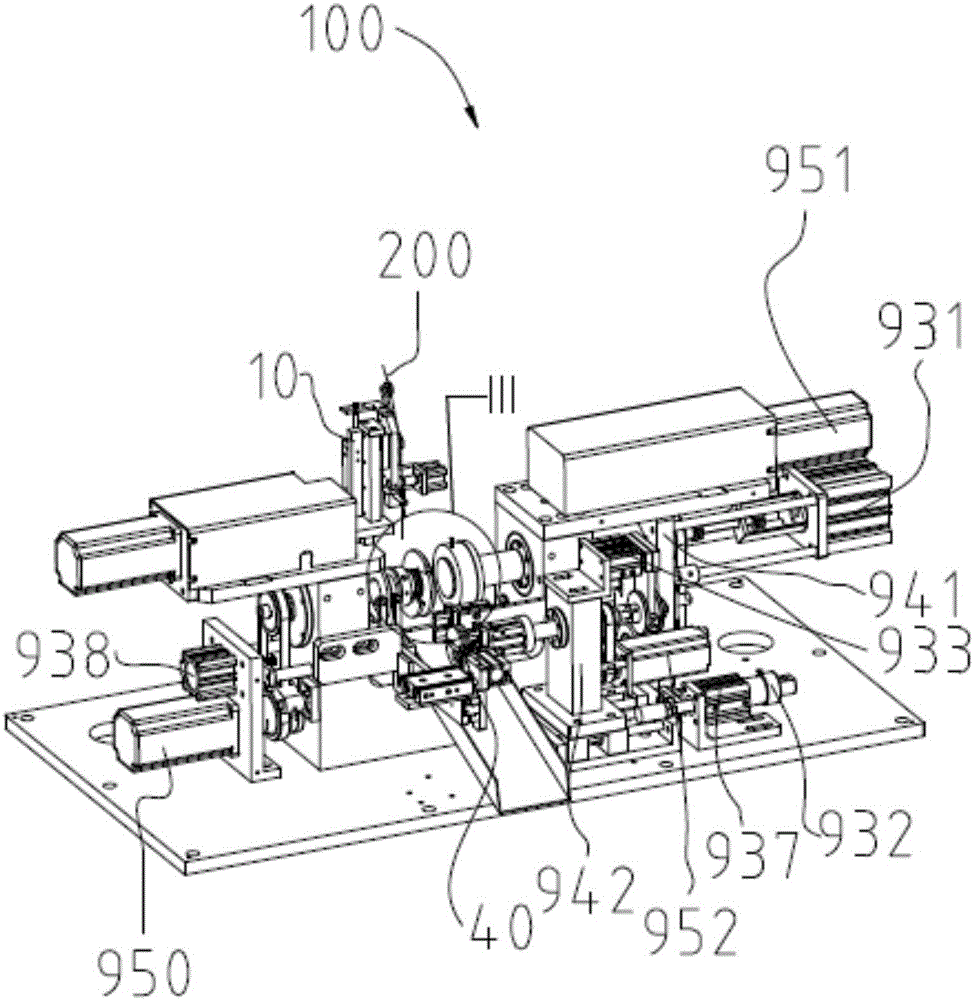

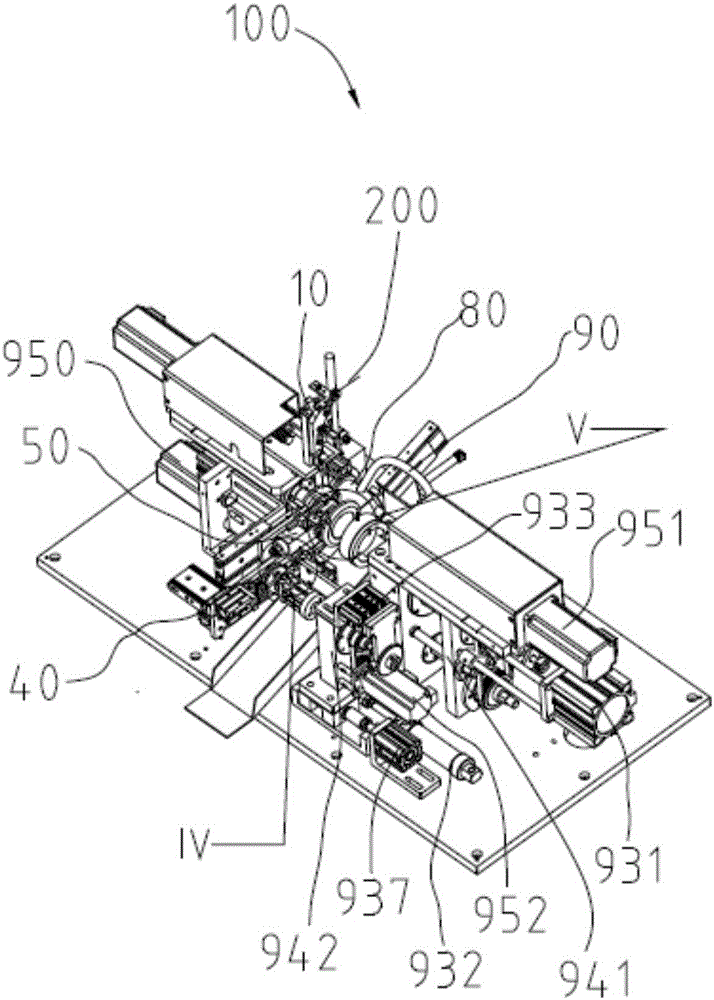

[0045] Please refer to figure 1 , the winding machine 100 provided by the present invention is used for winding N-layer coils, where N is an integer greater than or equal to 2.

[0046] In this embodiment, the N-layer coil is a 30-layer coil.

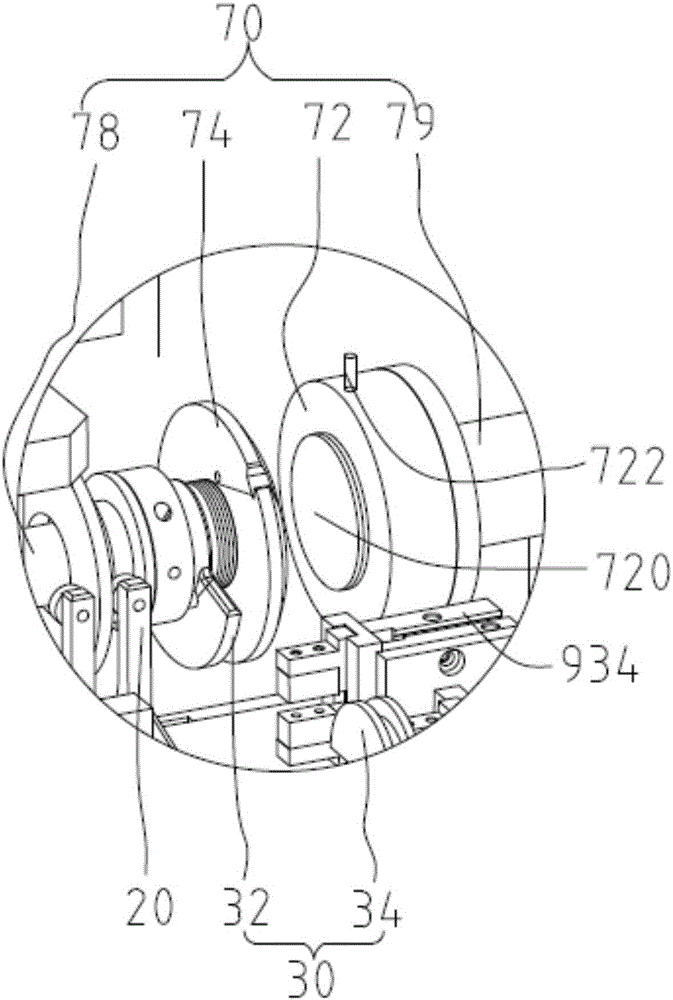

[0047] Please also refer to Figure 2 to Figure 4 , The winding machine 100 includes a wire arranging device 10 , a first wire pressing device 20 , a wire storage device 30 , a wire clamping device 40 , a wire cutting device 50 , a second wire pressing device 60 and a wire winding device 70 . The wire storage device 30 includes a first wire storage part 32 and a second wire storage part 34 , and the first wire pressing device 20 is installed on the first wire storage part 32 .

[0048] When winding, the wire arranging device 10 transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com