A circuit board control cabinet with replaceable pivot drive area

A technology of circuit board and drive area, applied in the maintenance field of circuit board control cabinet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

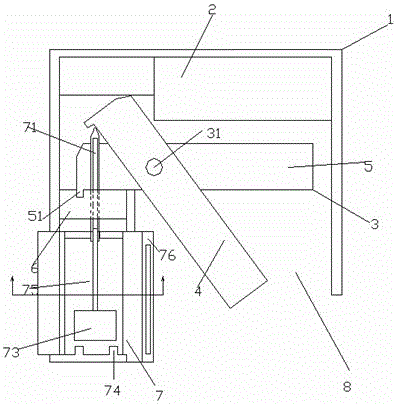

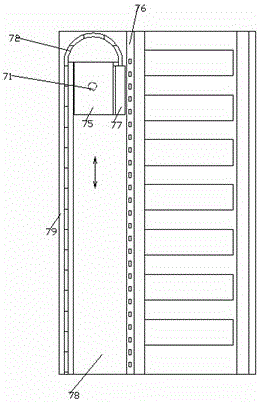

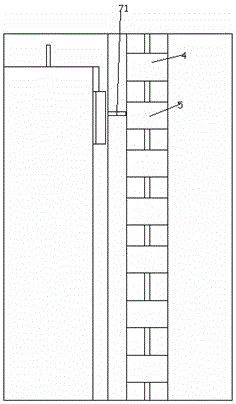

[0017] Combine below Figure 1-5 The present invention will be described in detail.

[0018] A circuit board control cabinet with a replaceable pivot drive area 41, including a cabinet housing 1, a ventilation system 2, a circuit board placement assembly 3, a fixing frame 6, and a lifting circuit board opening part 7, wherein the cabinet housing 1 is used for In order to accommodate the ventilation system 2, the circuit board placement assembly 3, the fixing frame 6 and the lifting type circuit board opening part 7 and has a doorway area 8, the doorway area 8 is used for the user to operate and maintain the circuit board control cabinet, The ventilation system 2 is used to input cooling air into the cabinet shell 1, and the circuit board placement assembly 3 is provided with a column shaft 31 on which a plurality of circuit boards 4 are pivotally mounted from top to bottom , 5, each of the circuit boards can pivot independently of each other relative to the column shaft 31; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com