Friction pad assembly for disc brakes

一种盘式制动器、摩擦垫的技术,应用在制动器的部件、制动器类型、带有受压制动面的制动器等方向,能够解决不能维持摩擦面积、不能确保制动特性等问题,达到减轻重量、成本降低、降低加工精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

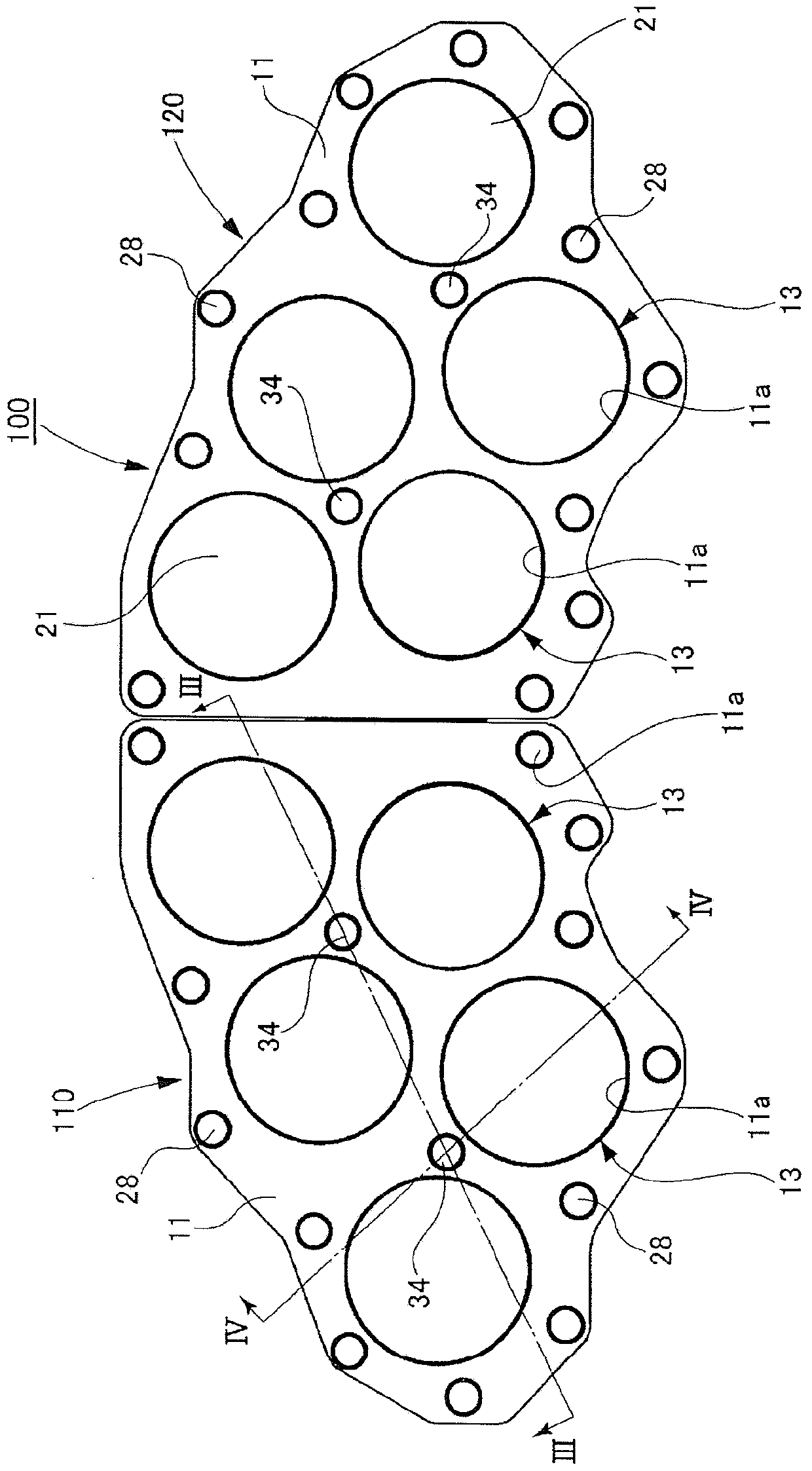

[0073] A description will be given specifically of a disc brake friction pad assembly according to an embodiment of the present invention with reference to the accompanying drawings.

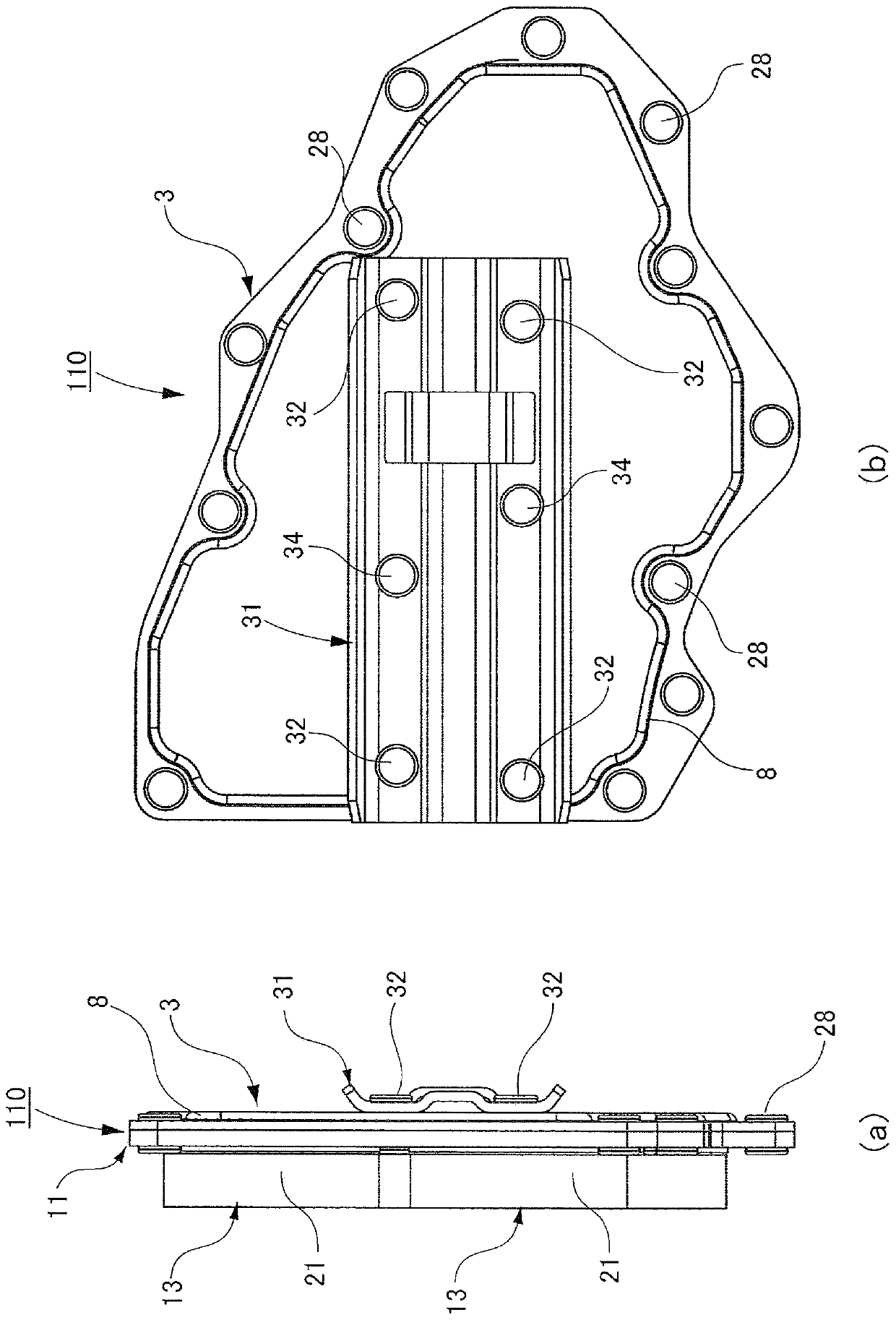

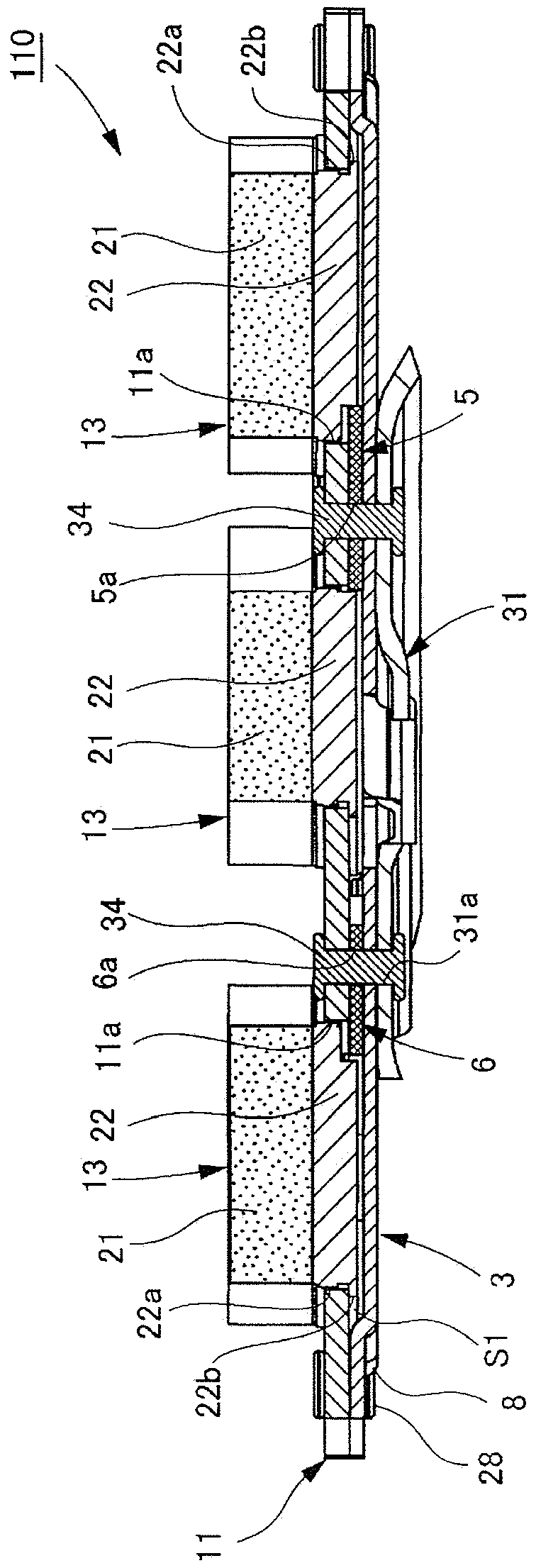

[0074] Figure 1 to Figure 4 A disc brake friction pad assembly according to an embodiment of the invention is shown.

[0075] Such as figure 1 As shown, the disc brake friction pad assembly 100 according to this embodiment is used for a railway vehicle disc brake device, and consists of two-unit friction pads arranged side by side in the circumferential direction of a disc rotor (not shown) provided on a wheel shaft Components 110 and 120 make up.

[0076] The unit friction pad assemblies 110 and 120 are similarly constructed. They are respectively opposed to the disc rotor and can be driven by actuators placed in calipers (not shown) to advance and retreat relative to the disc rotor.

[0077] Such as figure 2 (a) to Figure 4 As shown, the friction pad assemblies 110 and 120 each includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com