Hydraulic synchronization correction device

A deviation correction device and hydraulic synchronization technology, applied in the field of deviation correction devices, can solve the problems of inaccurate positioning of deviation correction work, inability to meet user needs, high labor consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

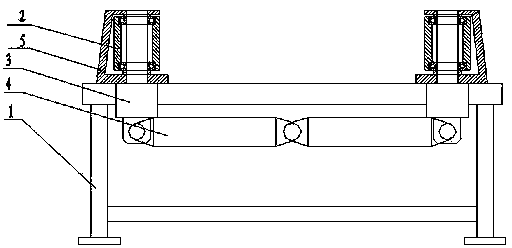

[0010] Such as figure 1 A hydraulic synchronous deviation correction device shown includes a deviation correction frame 1, a deviation correction roller 2, a support 3, an oil cylinder 4 and a deviation correction wheel seat 5, and symmetrically arranged deviation correction wheel seats 5 are installed on both sides of the deviation correction frame 1 , The correcting wheel base 5 is equipped with a hydraulically driven correcting roller 2, and the working platform of the correcting frame 1 is also provided with a support 3, and an oil cylinder 4 is installed on the support 3.

[0011] The above is only a preferred embodiment of the present invention, it should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications are also possible. It should be regarded as the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com