Transporting device for passageway part traversing

A conveying device and passage technology, applied in transportation and packaging, railway car body parts, railway vehicles, etc., can solve the problems of difficult to move parts smoothly, operators tripping, uneven ground, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

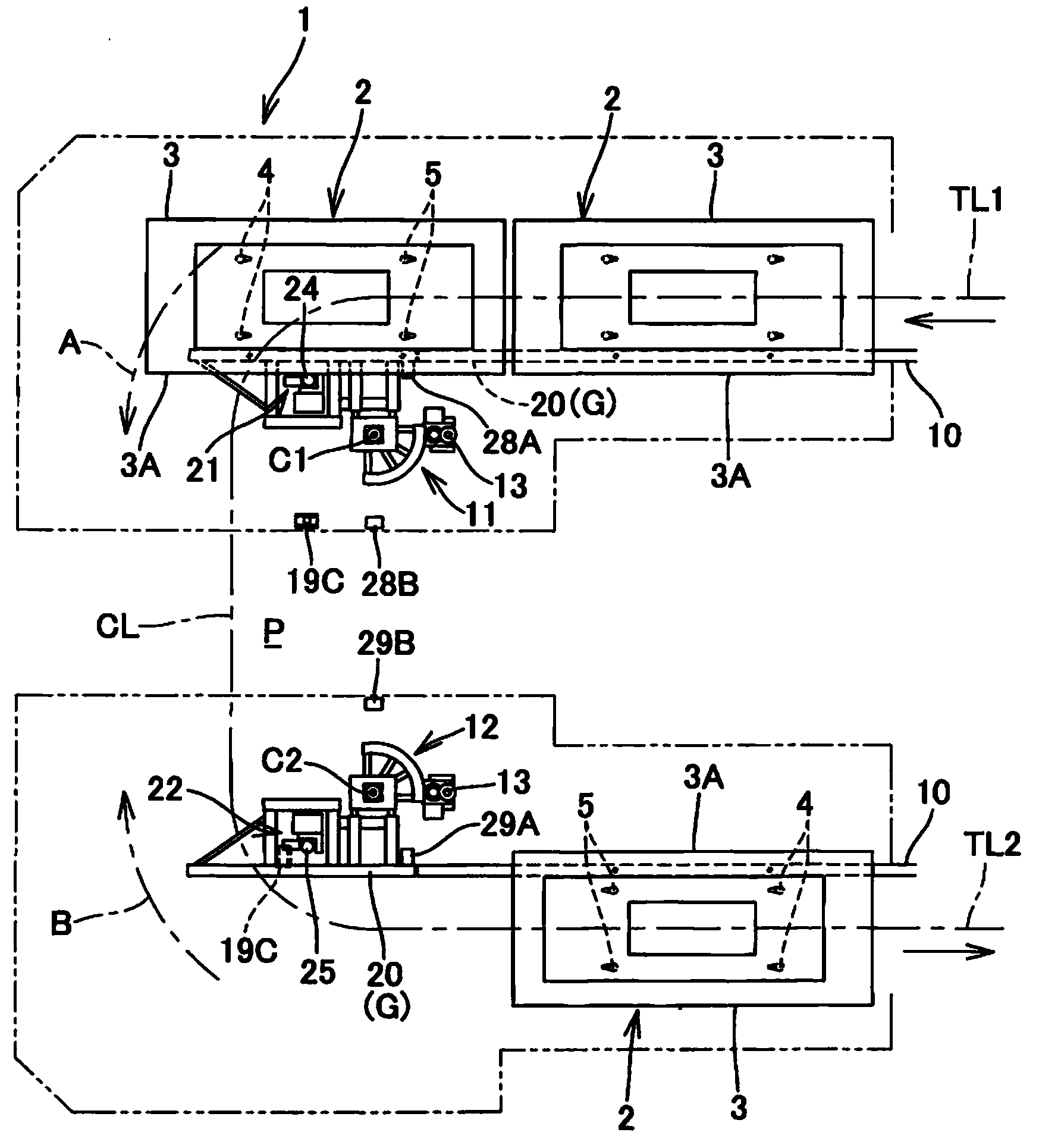

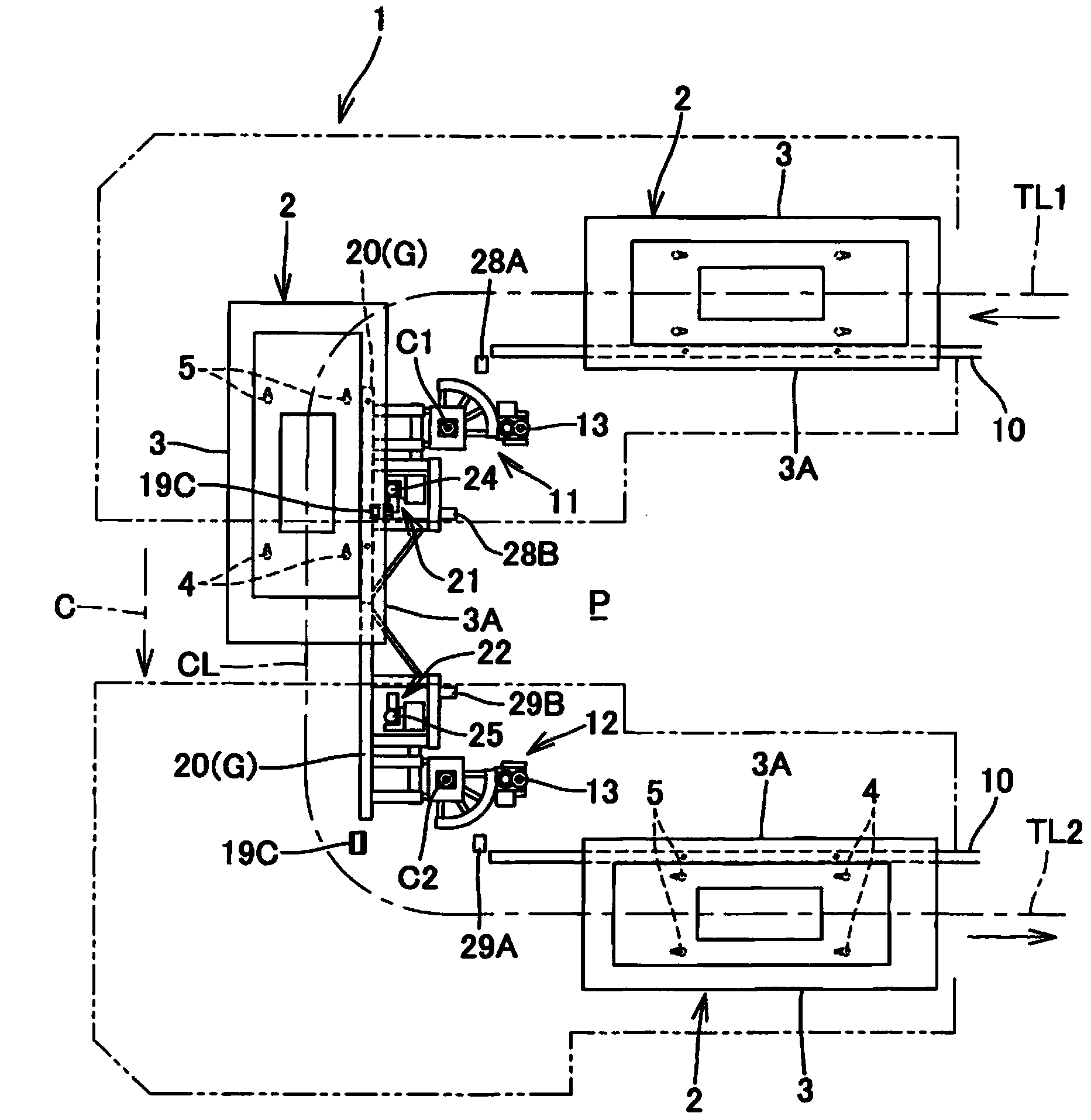

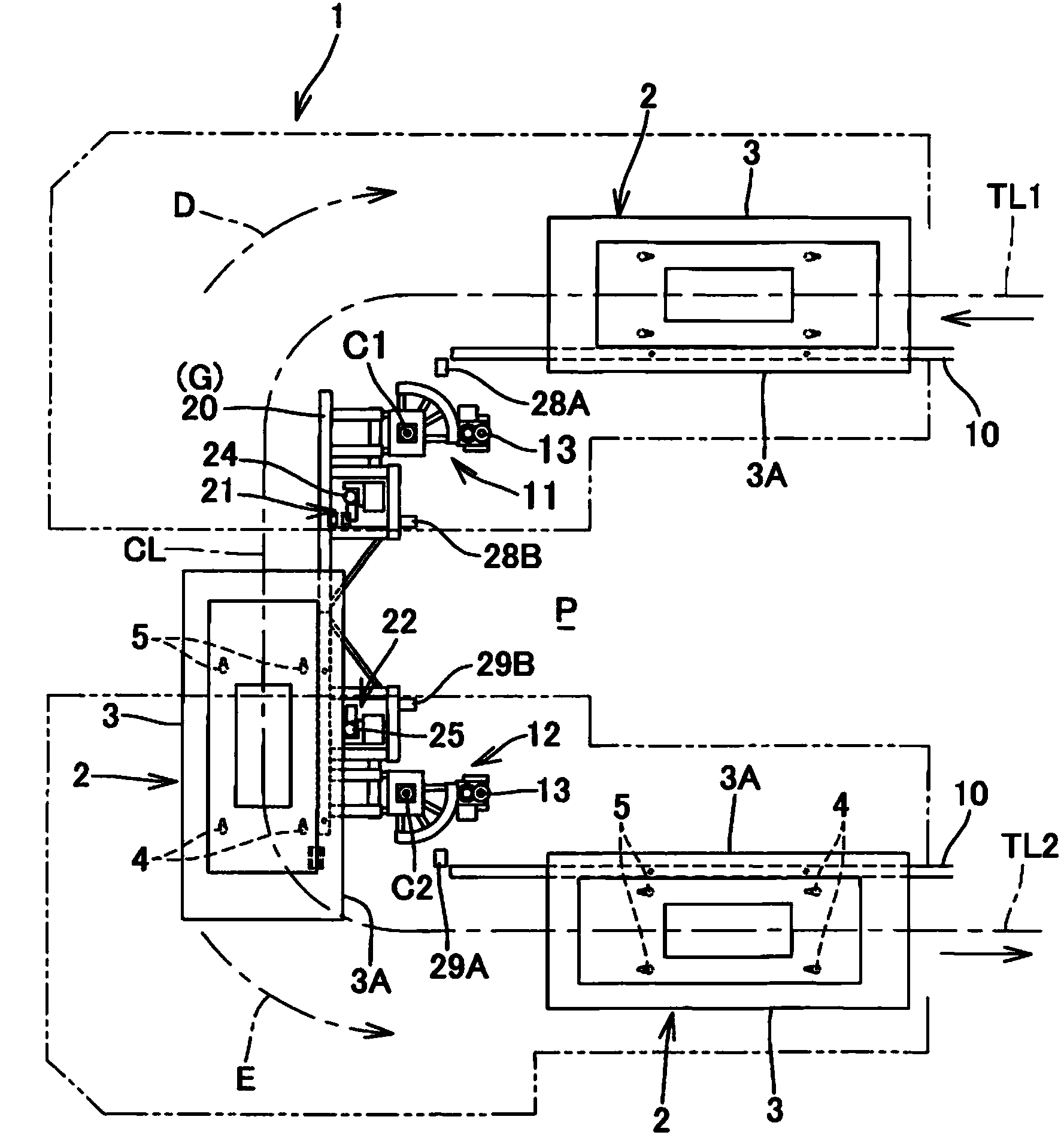

[0075] Such as Figure 1 ~ Figure 4 As shown in the schematic plan view, the conveying device 1 according to the first embodiment of the present invention is formed to include a parallel conveying line (the first conveying line TL1 as an outgoing line and a return line) for conveying objects not shown in the figure. The second transmission line TL2) between the transportation trolley 2 loaded with the object to be transported in the horizontal direction perpendicular to the transportation lines TL1 and TL2 to move the cross line CL, located in parallel to the first transmission line TL1 and second The crossing line CL is traversed between the transmission lines TL2 and along the path P of the transmission lines TL1 and TL2.

[0076] The relatively large conveying trolley 2 with the base 3 is equipped with left and right front wheels 4, 4 and rear wheels 5, 5 at the front and rear. These wheels 4, 4, 5, and 5 are rotating parts that rotate freely and the wheels rotate around a ver...

Embodiment approach 2

[0096] Such as Picture 10 As shown in the schematic plan view, the conveying device 1 according to the second embodiment of the present invention has a long distance (the length of the crossing line CL) between the parallel conveying lines TL1 and TL2 to cross the crossing line CL In this way, two parallel passages P1 and P2 are formed. In addition, there may be three or more such parallel passages.

[0097] On the crossing line CL, a fixed rail 30 connected to the movable rails 20, 20 of the first trolley rotating device 11 and the second trolley rotating device 12 is provided between the passages P1 and P2, and an inter-passage platform is provided The structure of the vehicle conveying devices 23 and 23 and other devices are the same as in the first embodiment.

[0098] Here, the inter-path trolley conveying devices 23 and 23 are friction-type driving devices, and the friction rollers 26, 27 are brought into contact with the friction surface 3A of the base 3 of the conveying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com