Insulation pipe fitting elbow containing high-density polyethylene reinforced bracket and manufacturing method

A technology of high-density polyethylene and pipe fittings, applied in the direction of elbows, heat preservation, pipe elements, etc., can solve the problems of uneven space of outer protective pipe, uneven heat preservation of polyurethane, and no support, so as to improve product quality and heat preservation effect , uniform distance and uniform layout distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

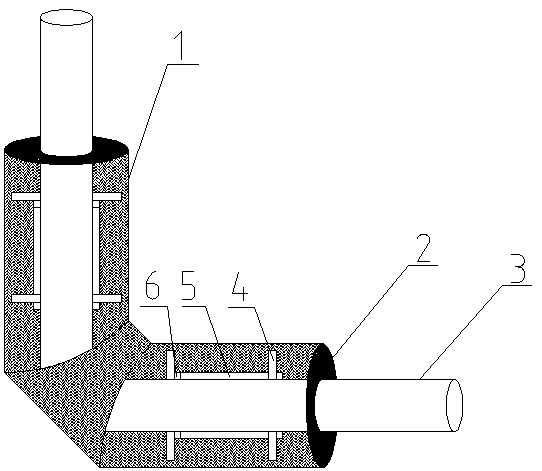

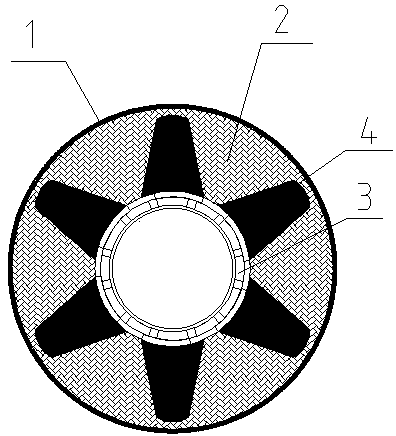

[0016] A thermal insulation pipe fitting elbow containing a high-density polyethylene reinforced bracket, which consists of: an elbow working tube 3, the outer side of the elbow working tube is covered with a high-density polyethylene reinforcing bracket 4, and the high-density polyethylene There is an outer protective tube 1 on the outside of the reinforced bracket, a hard polyurethane layer 2 is provided between the elbow working tube and the outer protective tube, and the vertical section of the elbow working tube is transitioned through a circular arc.

Embodiment 2

[0018] According to the thermal insulation pipe fitting containing the high-density polyethylene reinforced bracket described in Example 1, the bracket body of the high-density polyethylene reinforced bracket is a rectangular isosceles trapezoid, and one end of the high-density polyethylene reinforced bracket is a standard height The support 5, one end of the high-density polyethylene reinforced bracket is a contracted clip tail 6, and the clip end is clipped with the buckle at the bottom of the support.

Embodiment 3

[0020] According to the thermal insulation pipe fitting elbow with the function of monitoring leakage points described in embodiment 1 or 2, the pipe diameter of the elbow working pipe is 15mm-2000mm, the thickness of the polyurethane protective layer is 30-200mm, and the The thickness of the polyethylene outer protective tube is 1-30mm, and the signal wires are metal conductive bare wires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com