Fire interface

An interface and fire protection technology, applied in the interface field, can solve the problems of poor interface strength, no self-locking device, unable to withstand the impact of high-strength water supply pressure, etc., and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] There are many types of fire-fighting interfaces, and the technical solution of the present invention will be further described below by taking the hose interface as an example.

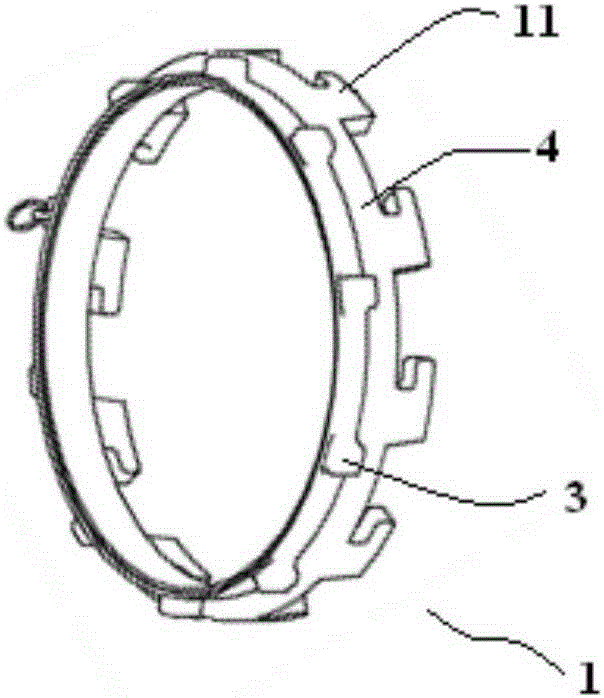

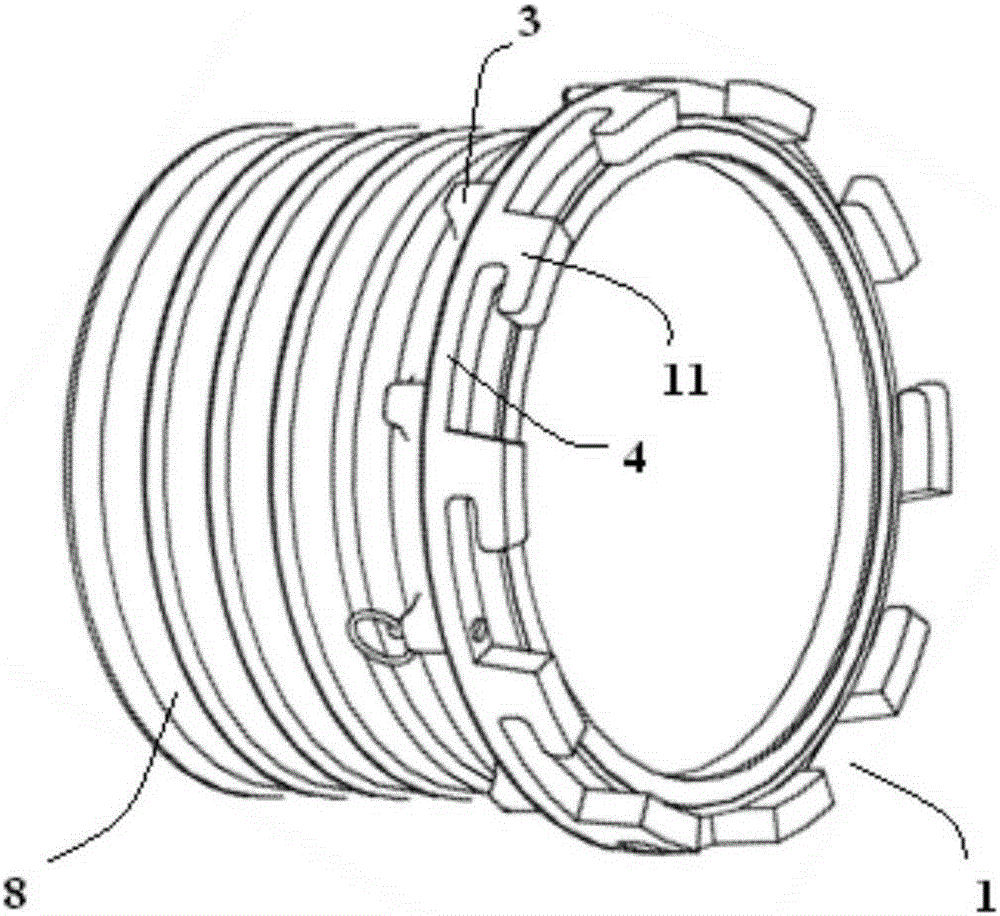

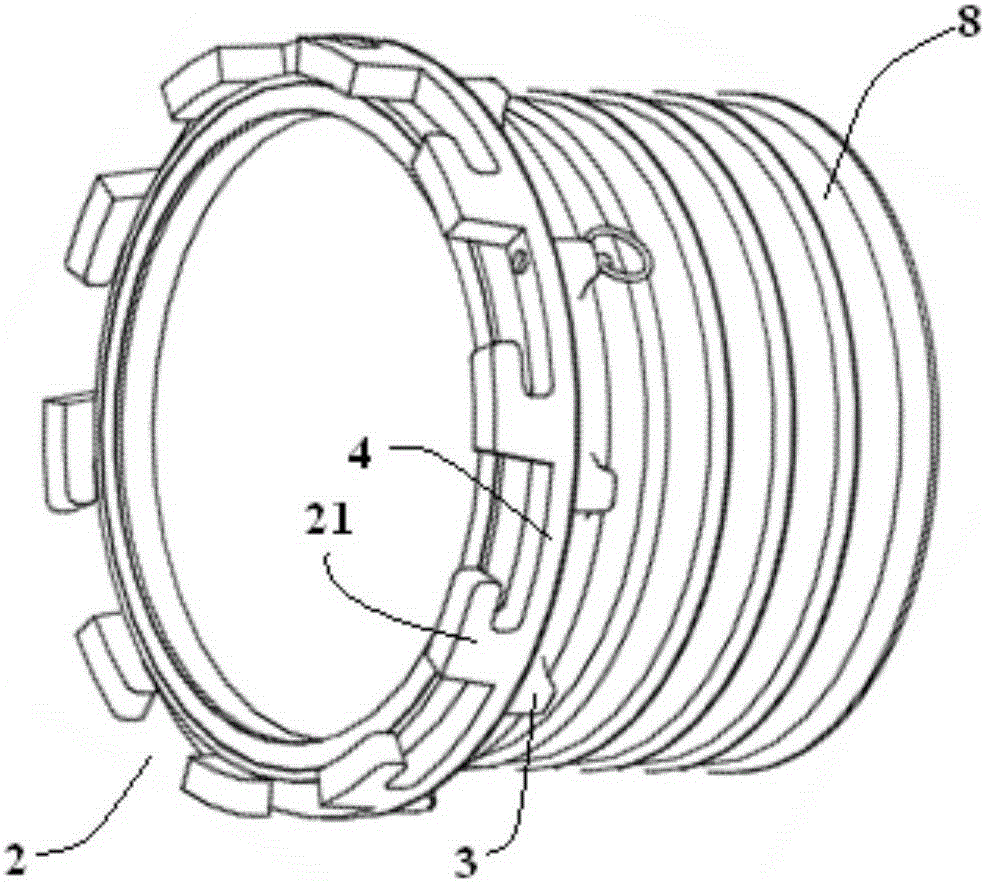

[0019] Such as figure 1 As shown, the fire-fighting interface includes a left interface 1 and a right interface 2 (the claws of the left and right interfaces have the same shape, and the right interface is turned over to become the left interface). The buckle 11 extends axially from its end face for a section and then bends to form a claw-shaped hook groove; the end face of the right interface 2 is uniformly distributed with right claws 21 along the circumference, and the right claw 21 extends axially from its end surface for a section and then bends to form The claw-shaped hook groove, wherein the bending directions of the left and right claws are opposite; the left and right claws are buckled together to form a fire protection interface.

[0020] Such as figure 2 , 3 , 4, in addition to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com