Torque test tool for push back type torsion spring

A torsion spring and torque testing technology, applied in the field of fixtures, can solve the problems of inaccurate measurement of spring torque, torsional displacement changes in the middle working circle, etc., to ensure torsional displacement and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

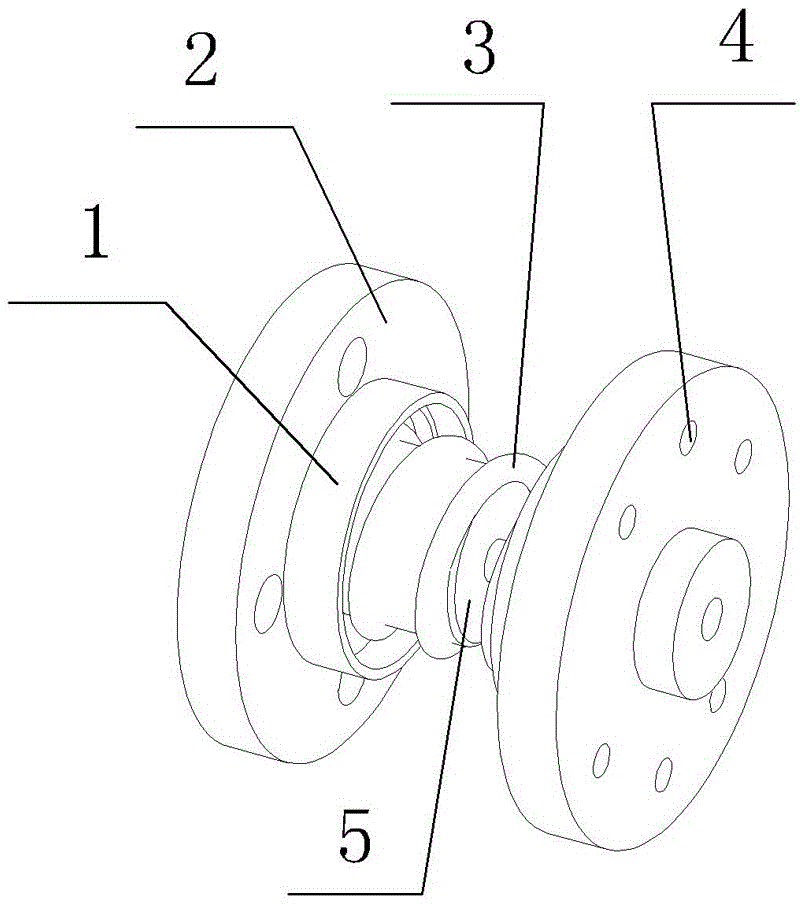

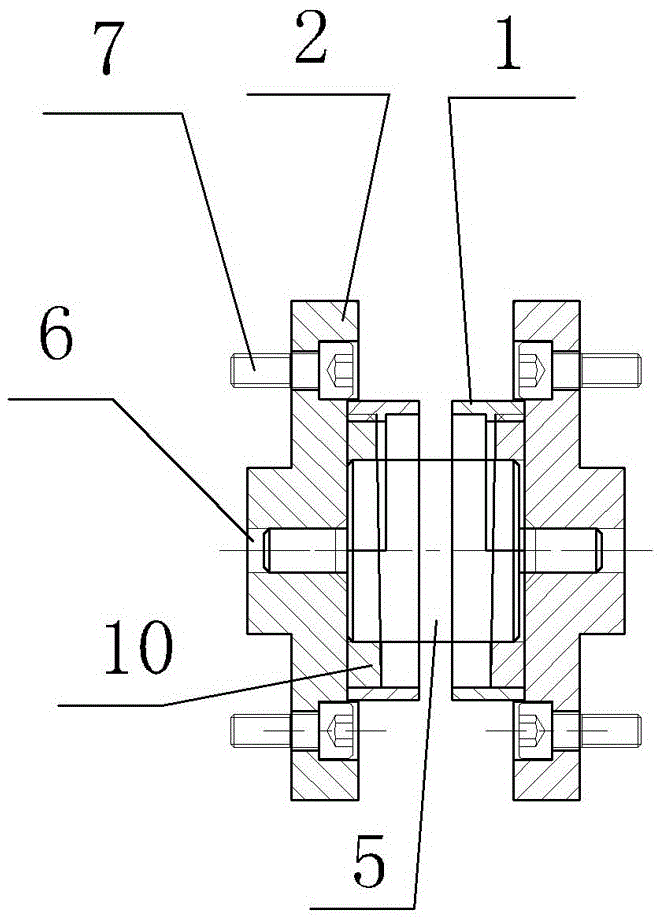

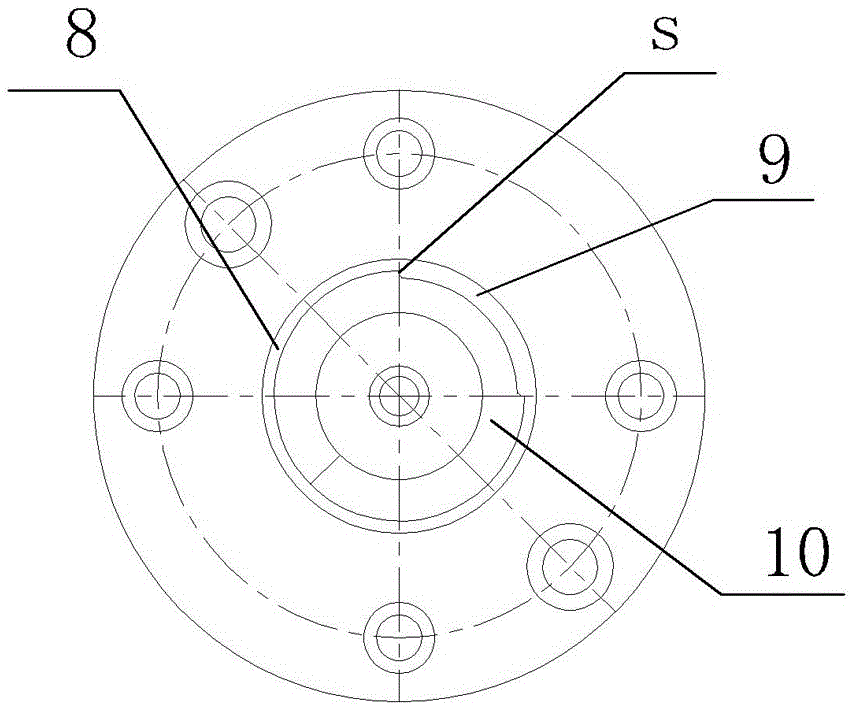

[0022] Such as figure 1 with 2 As shown, a torque testing tool for reverse thrust torsion springs includes two tooling seats 2 installed oppositely. The two tooling seats 2 are in the shape of a flange. The outer ring of the working device 2 is uniformly provided with bolt holes 4 , Fix the working device on the flange plate (not shown) of the torque testing machine by bolt 7. Such as image 3 with 4 As shown in and 5, a spacer block 10 with a circular cross-section is integrally formed in the center of the tooling seat 2. The end face of the spring 3 to be tested is placed on the spacer block 10, and the spacer block 10 is provided with a bolt angle. The spiral lift of 10 is designed to be flat at the lift height of 225°, so that the spring to be tested is flush with the supporting ends of the cushion block, that is, the cushion block flattens the end surface of the spring to be tested. A stepped through hole 6 is opened in the center of the cushion block 10, and a positioning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com