A replacement tool for tension insulator strings

A technology of tension insulator strings and tools, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of bulky and bulky hard insulating rods and bottle holders, difficulty in high-altitude operation, high labor intensity, and limited carrying and transportation. Achieve the effects of improving the level of safe and economical operation, improving the management system of live working tools and equipment, and simplifying the working method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

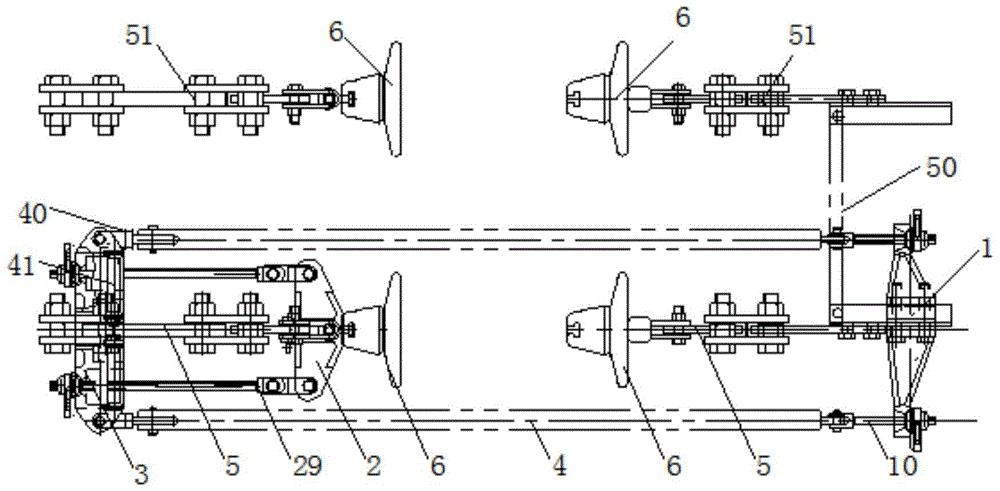

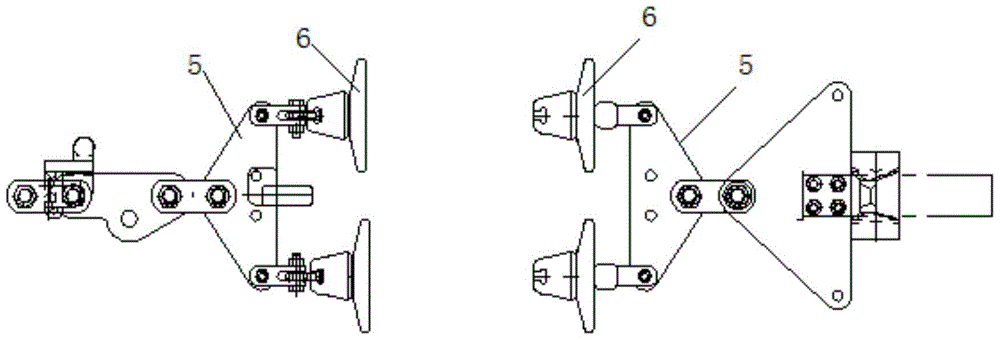

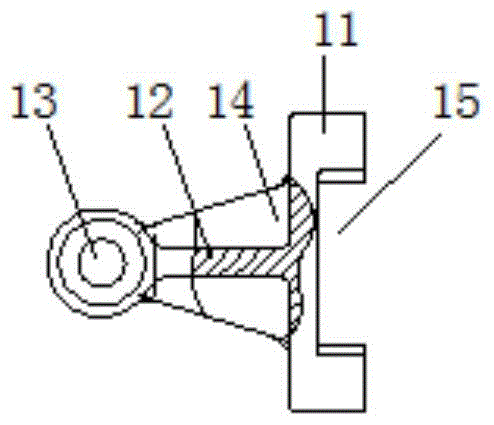

[0027] Figure 1 to Figure 5 It shows the specific structure of the special tool for live replacement of tension insulator strings in the present invention, which includes two insulating ropes 4 arranged in parallel, the front and rear ends of the insulating ropes 4 are respectively connected to the front card 1 and the rear card 3, and the front card 1. The left and right ends are connected to the front end of the insulating rope through the linear anti-twist screw 10. The left and right ends of the rear card 3 are connected to the rear end of the insulating rope 4. A middle card 2 is arranged between the two insulating ropes in front of the rear card. The left and right ends of the middle card 2 are respectively provided with a tightening lead screw 29 to connect with the rear card, the rear side of the front card 1 is connected to the tension insulator 6 through the connecting plate 5, and the front side of the rear card 3 is connected through the connecting plate 5 It is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com