Free-range poultry house feeding device manufacture method

A production method and poultry house technology, which is applied in the field of breeding, can solve the problems of high cost, etc., and achieve the effect of simple structure, simple product structure and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

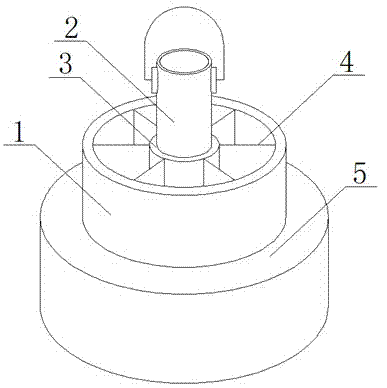

[0021] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention.

[0022] A kind of manufacturing method of the feeding device in the free-range poultry house of the present invention, wherein, comprises the following steps: A, select some stainless steel plates at first, the thickness of stainless steel plate is 2mm-3mm, use stamping machine, feed tray, feed box and The base is shaped and stamped; B. The feeding tray, feed box and base are welded and fixed from bottom to top in the order of the base, feed tray and feed box; C. Install large mesh grids and small mesh nets in the feeding tray grid, so that the large grid grid and the small grid grid can rotate in the feeding tray with the feed box as the center of circle.

[0023] A feeding device in a free-range poultry house made by this method comprises a feeding tray 1, a feed box 2 connected to the feeding tray 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com