Novel badminton and manufacturing method thereof

A new structure and badminton technology, applied in the field of badminton, can solve the problems of easy wear and tear, and achieve the effect of firm fixing of feathers, good flight characteristics and good fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

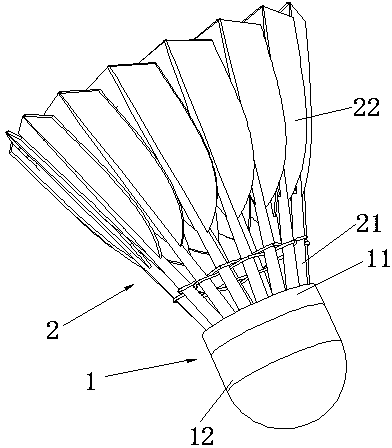

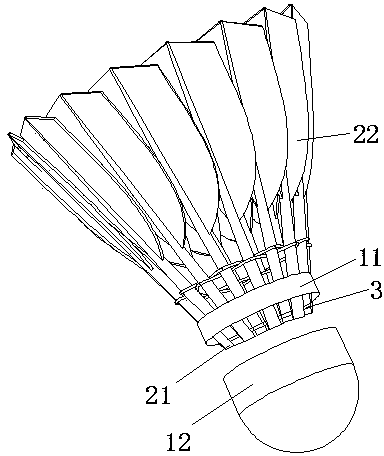

[0024] Please refer to the attached Figure 1-2 , Embodiment 1 of the present invention includes:

[0025] A shuttlecock with a new structure, comprising a ball head 1, 16 feathers 2 firmly connected with the ball head 1, the ball head 1 includes a front ball head 11, a rear ball head 12 firmly connected with the front ball head 11, and the front ball head 11 There are 16 through holes arranged on the top, and a plurality of through holes are arranged equidistantly in a circle; the feather 2 includes a feather stalk 21 and a pinna 22 firmly fixed on the feather stalk 21, and the head of the feather stalk 21 is inserted and runs through the front The through hole on the ball head 11, and the head of the feather stalk 21 is also provided with a blocking coil 3 that binds the 16 feathers 2 together and is in contact with the surface of the front ball head 11.

[0026] The traditional badminton head is integrated, and the feather stem is inserted into the integrated head, and fix...

Embodiment 2

[0036] Please refer to the attached image 3 , Embodiment 2 of the present invention includes:

[0037] Compared with Example 1, in this Example 2, the rear ball head and the front ball head are sewn together by a long thread 4 to achieve a stable connection, and the long thread 4 passes through the rear ball head and the front ball head in turn, and this reciprocating action is regarded as a periodic action , complete the stitching through multiple cyclical actions.

[0038] The blocking coil is formed by winding a wire end-to-end. The blocking coil binds 16 feathers in a circular distribution and maintains the circumferential distribution structure.

[0039] A manufacturing method of a shuttlecock with a novel structure, comprising

[0040] Step 1, prepare the above-mentioned front ball head, rear ball head, feather stem, pinna and blocking coil;

[0041] Step 2: Pass the heads of the feather stalks of 16 feathers one by one through the through hole of the front ball head...

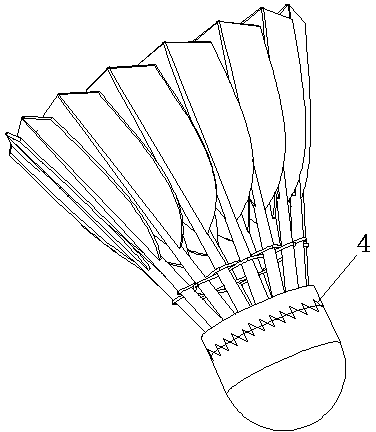

Embodiment 3

[0044] Embodiment 3 of the present invention includes:

[0045] Compared with Embodiment 1, in Embodiment 3, the rear ball head and the front ball head are bonded by glue to achieve a stable connection.

[0046] The blocking coil is formed by winding 16 wires end-to-end in sequence, and the blocking coil binds the 16 feathers in a circular distribution and maintains the circumferential distribution structure.

[0047] A manufacturing method of a shuttlecock with a novel structure, comprising

[0048] Step 1, prepare the above-mentioned front ball head, rear ball head, feather stem, pinna and blocking coil;

[0049] Step 2: Pass the heads of the feather stalks of 16 feathers one by one through the through hole of the front ball head, then put the blocking coil on the head of the feather stem passing through the through hole, and then place the locking coil and the rear ball Glue is applied to the pit surface of the head;

[0050] Step 3, apply glue on the bonding surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com