A high pressure filter press

A filter press, high-pressure technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems that cannot meet the requirements of tailings processing, high difficulty, high energy consumption, etc., and achieve filter press and unloading The material process is simple and convenient, the equipment height is small, and the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with the following examples.

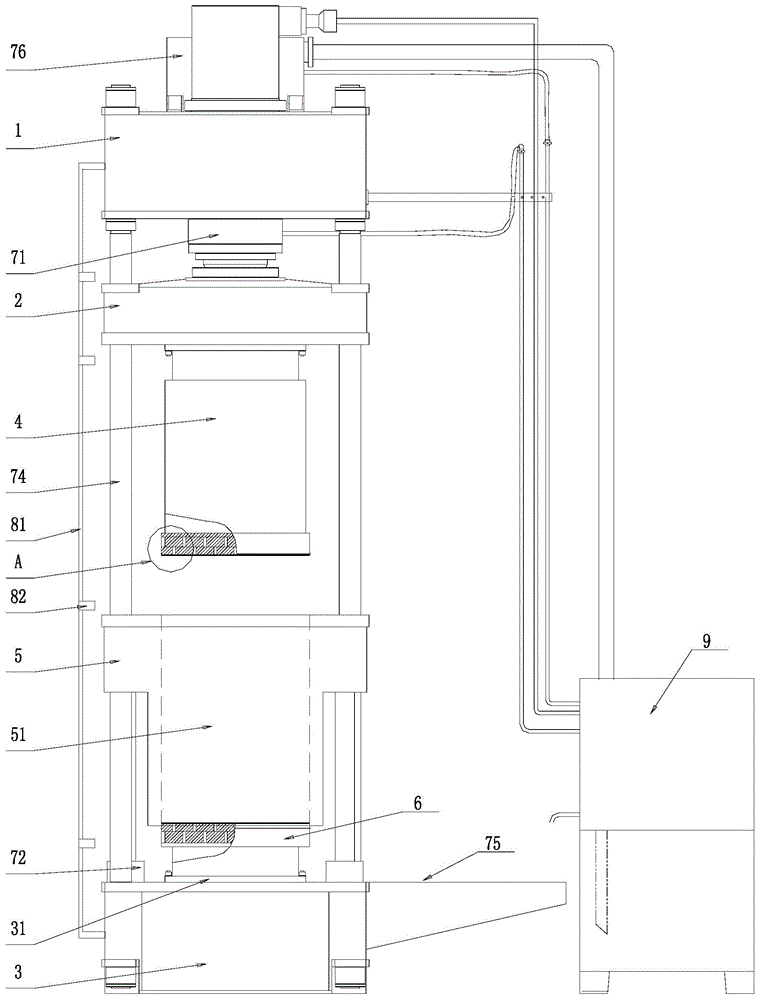

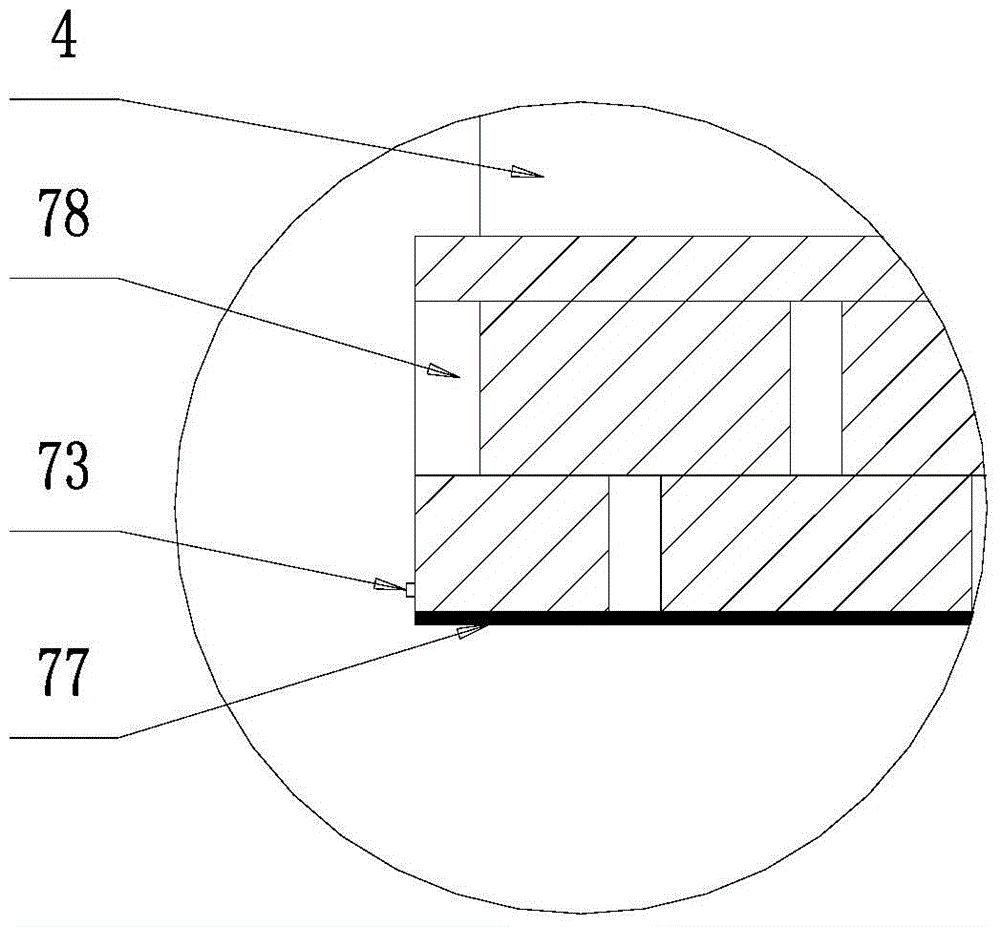

[0026] like figure 1 Shown, a kind of high-pressure strong filter press comprises upper beam 1, movable beam 2, lower beam 3, upper mold 4, middle mold 5, lower mold 6 and driving equipment;

[0027] The upper beam 1 and the lower beam 3 are fixedly connected by a plurality of vertical columns 74; the movable beam 2 and the middle mold 5 are installed on the column 74, and are provided with guide holes, and the guide holes are connected with the The column 74 cooperates so that the movable beam 2 and the middle mold 5 can move up and down along the column, and the movable beam 2 is placed above the middle mold 5;

[0028] The driving device includes an upper oil cylinder 71 and a lower oil cylinder 72; the upper oil cylinder 71 is fixed on the upper beam 1 to drive the movable beam 2 to move up and down, and the working pressure of the upper oil cylinder 71 is 25Mpa-30Mpa; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com