Photoelectric button counting machine

A counting machine and photoelectric technology, applied in the field of photoelectric button counting machine, can solve the problems of slow speed and low accuracy, and achieve the effect of fast counting speed, high accuracy and saving labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

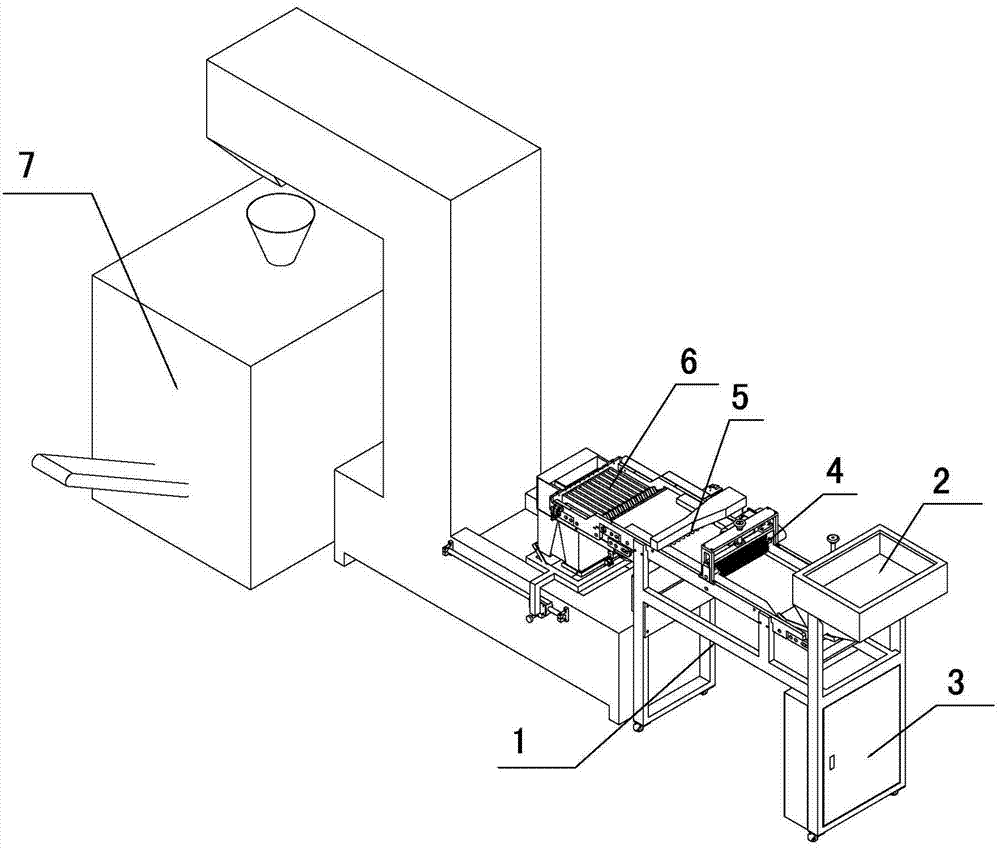

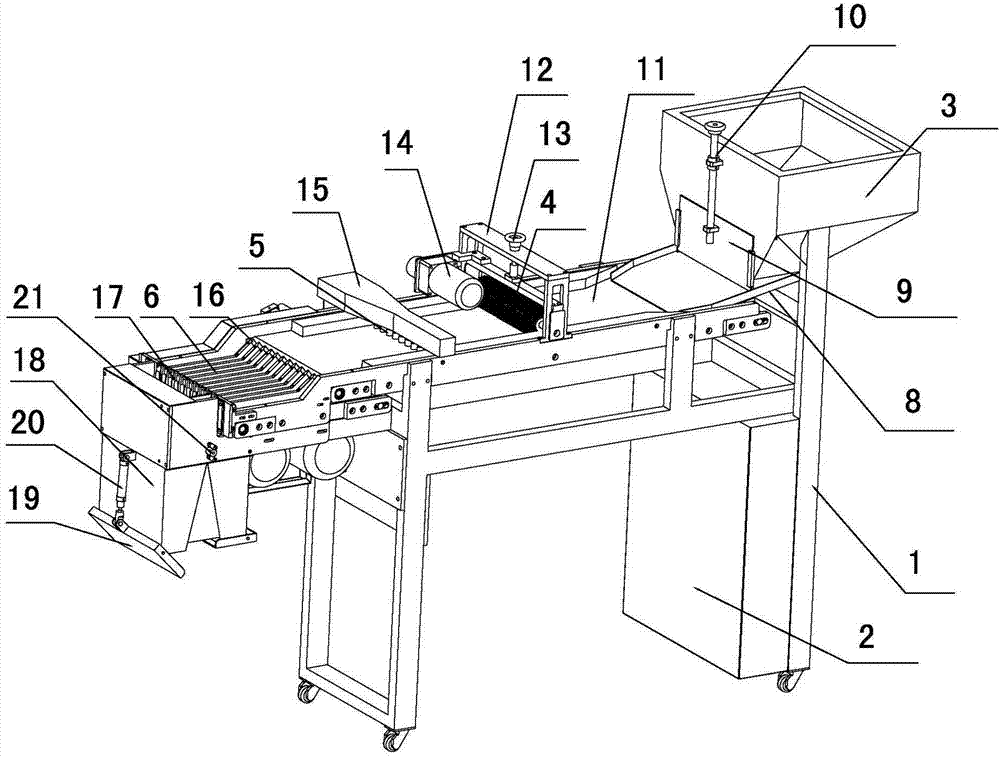

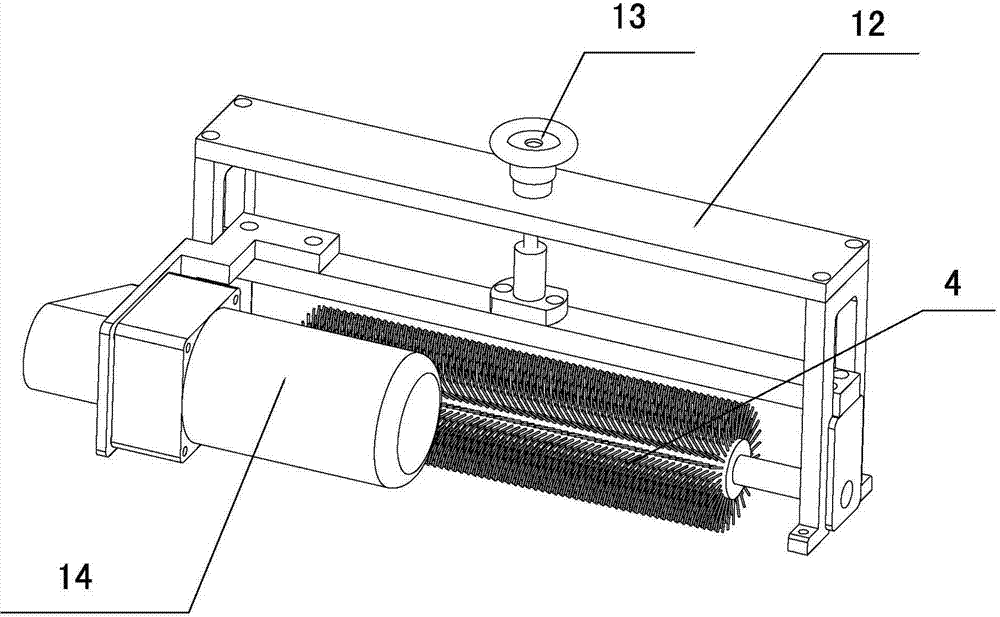

[0025] Please see attached figure 1 To attach Image 6 , the present invention mainly comprises frame 1, upper hopper 2, conveyer belt 11, feeding dividing plate 6 and lower hopper 18, and frame 1 is the main support structure of the present invention, and upper hopper 2 is fixedly installed on frame 1, In this embodiment, the upper hopper 2 is realized by a vibration plate, the bottom of the upper hopper 2 is provided with a vibrating chassis 8, the outlet of the upper hopper 2 is arranged at the side, and the outlet of the upper hopper 2 is equipped with a discharge baffle 9, and the upper hopper 2. A discharge adjustment rod 10 is installed on the outer surface, and the discharge adjustment rod 10 is used to adjust the height of the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com