Design method and product of double-sided bidirectional jacquard fabric

A double-sided, fabric technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of single weave structure on the reverse side and low utilization rate of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

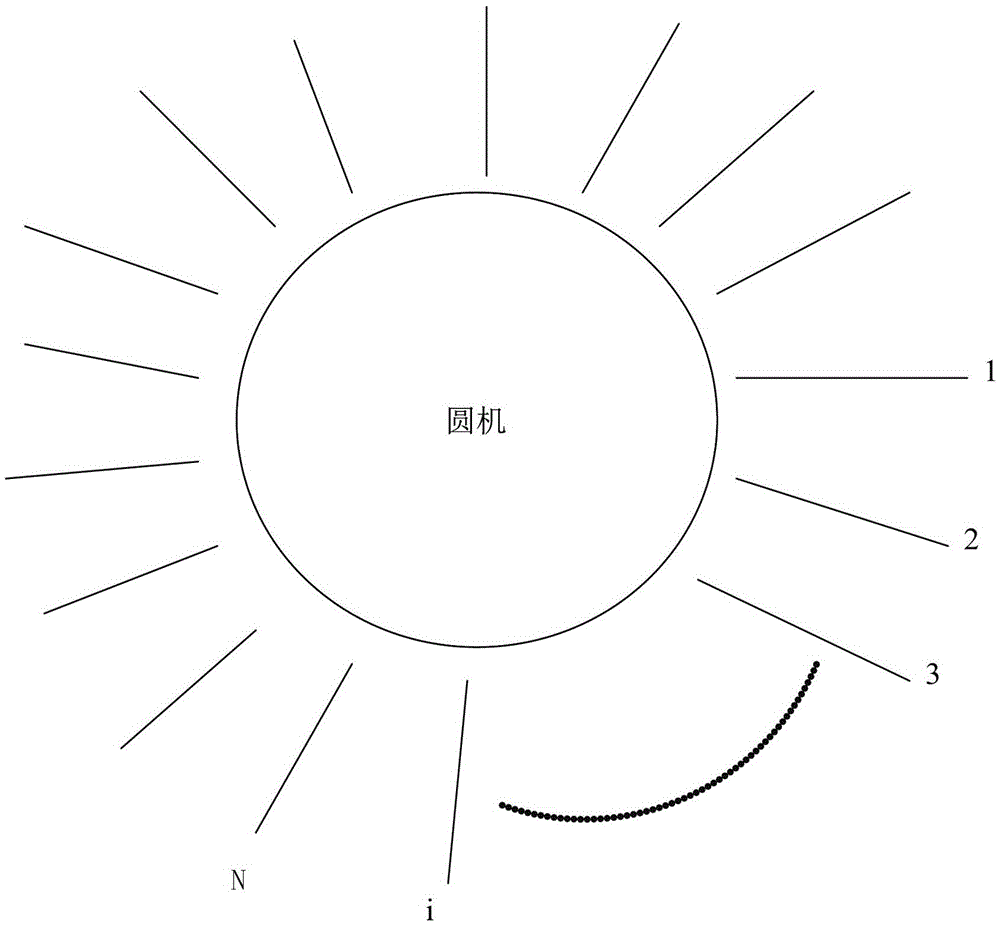

[0039] 2-color jacquard craft

[0040] (1) Yarn threading design: the dyed yarn cycle is 2, that is, dyed yarn 1 is worn on the 1st, 3, 5, 7... odd-numbered roads, dyed yarn 2 is worn on the 2nd, 4, 6, 8... even-numbered roads, The two yarns have different colors, and at the same time, taking into account the weight of the fabric, adjust the bending depth, yarn feeding length, and pulling tension to ensure uniform density on the front and back.

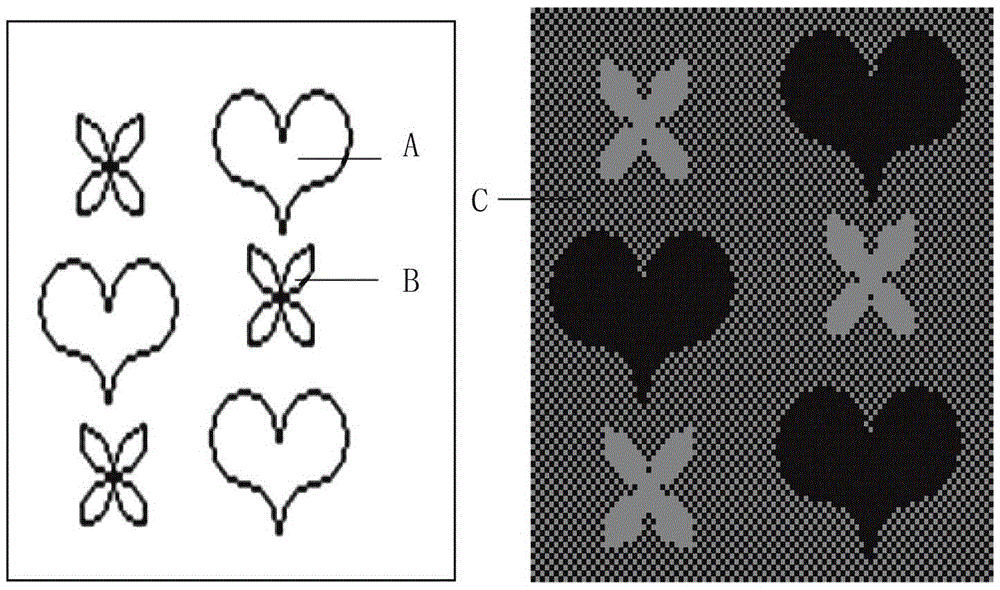

[0041] (2) Pattern design: such as Figure 4 As shown, the design and color area A is the front pattern, the design and color area B is the reverse pattern, and the area C is the shading area. At this time, the front and back patterns are superimposed on the same pattern diagram, but they are independent and do not overlap each other.

[0042] (3) Weaving process: such as Figure 5As shown, when knitting in the first way, all the needles of the needle cylinder in the design and color area A in the dotted line frame are knitted, and ...

Embodiment 2

[0044] 3-color jacquard craft

[0045] (1) Yarn threading setting: the colored yarn cycle is 3, that is, colored yarn 1 is worn on the 1st, 4, 7, 10... road, colored yarn 2 is worn on the 2nd, 5, 8, 11... road, colored yarn 3 is worn on 3, 6, 9, 12... on the road number, and the yarn color is different. At the same time, taking into account the weight of the fabric, adjust the bending depth, yarn feeding length, and pulling tension to ensure uniform density on the front and back.

[0046] (2) Pattern design: such as Image 6 As shown, the design and color areas A and B are the front pattern, the design and color area C is the reverse pattern, and the area D is the shading area. At this time, the front and back patterns are superimposed on the same pattern diagram, but they are independent and independent of each other. Overlapping; the pattern areas A and B are represented by black and gray respectively, the pattern area C is represented by white, and the area D is covered w...

Embodiment 3

[0049] 4-color jacquard craft

[0050] (1) Yarn threading setting: the colored yarn cycle is 4, that is, colored yarn 1 is worn on the 1st, 5, 9, 13... roads, colored yarn 2 is worn on the 2nd, 6, 10, 14... roads, colored yarns 3 is worn on 3,7,11,15... road, colored yarn 4 is worn on the 4th, 8,12,16... road, and yarn color is different. At the same time, taking into account the weight of the fabric, adjust the bending depth, yarn feeding length, and pulling tension to ensure uniform density on the front and back.

[0051] (2) Pattern design: such as Figure 8 As shown, the pattern areas A and B are the front pattern, the pattern areas C and D are the back pattern, and the area E is the shading area. At this time, the front and back patterns are superimposed on the same pattern diagram, but they are independent of each other. do not overlap each other. The color areas A and B are respectively represented by black and light gray, the color areas C and D are respectively rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com