A Municipal Shield Tunnel

A shield tunneling and municipal technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems affecting the normal layout of pipelines and cables, difficult horizontal installation of brackets, and harsh construction environment, etc., to facilitate material transportation and save money. The effect of tunnel pipe capacity and rational use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below:

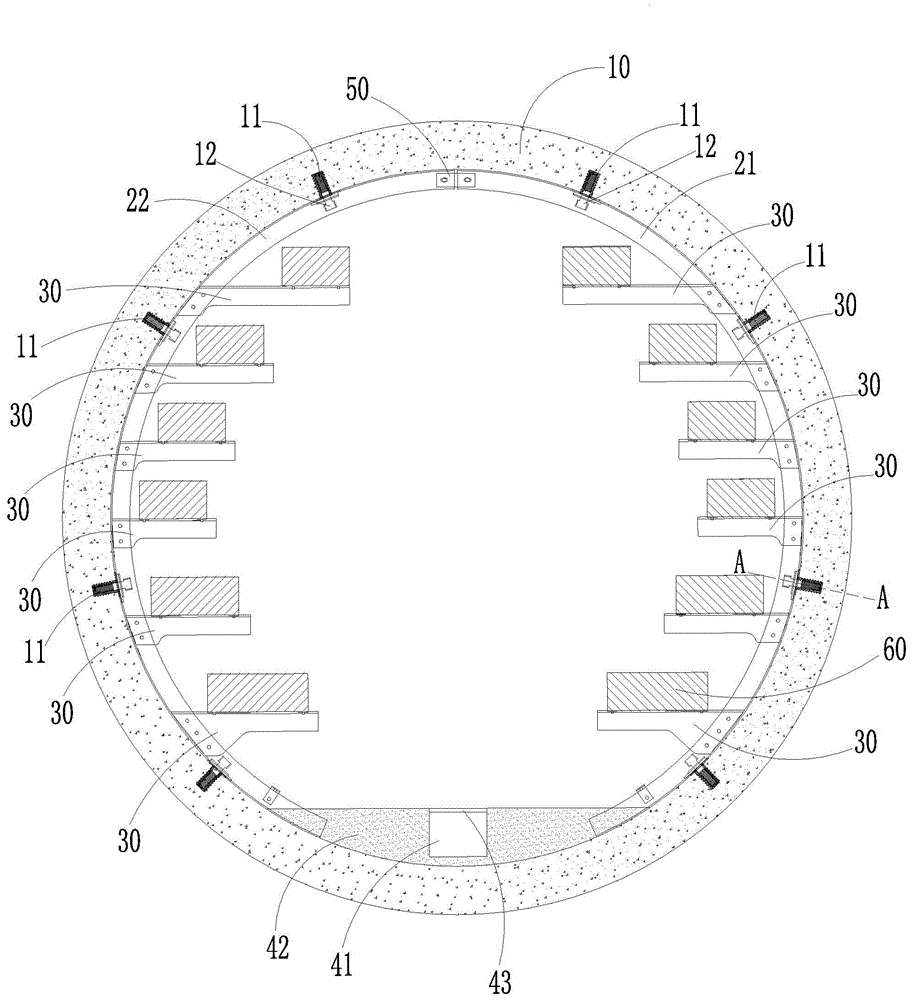

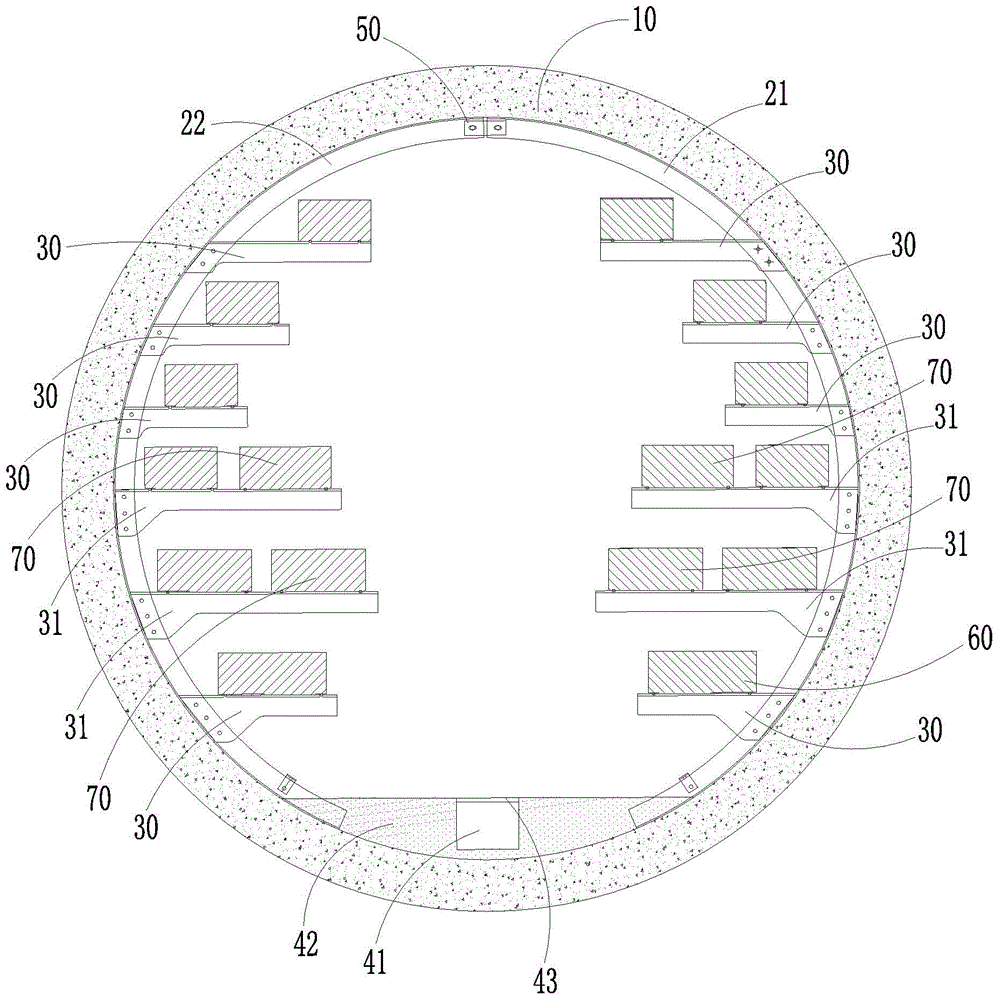

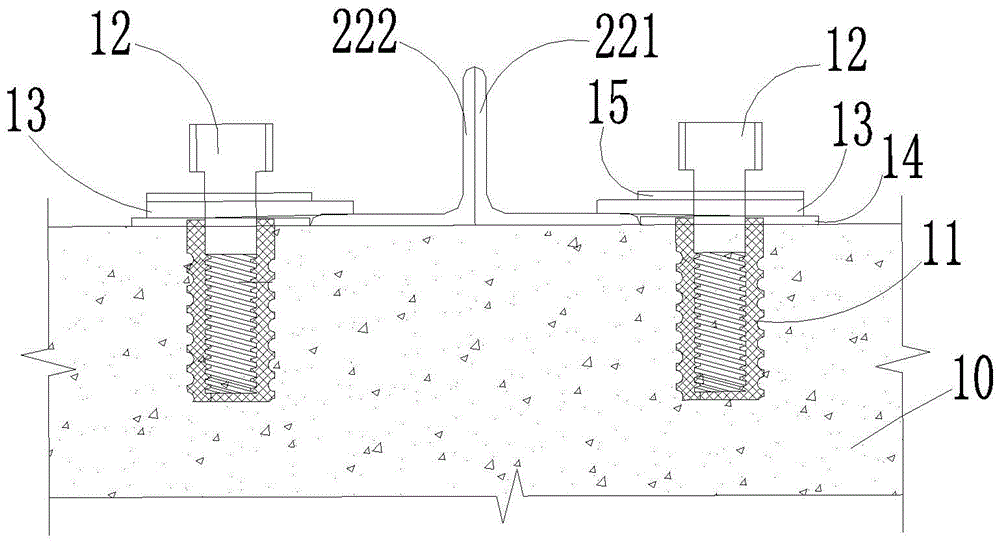

[0035] Such as figure 1 As shown, the municipal shield tunnel of the present invention includes a plurality of prefabricated pipes 10 connected in series, and an arched steel ring beam. The inner wall of the prefabricated pipe 10 is embedded with a plurality of installation holes 11 along the circumferential direction. The ring beam is closely attached to the inner wall of the prefabricated pipe 10, and the steel ring beam has an installation frame facing the axis of the tunnel, please refer to figure 2 , the circumferential direction of the installation frame is uniformly connected with a plurality of first brackets 30 and second brackets 31, the second brackets 31 are installed at the installation frame corresponding to the position of the waist of the tunnel, and the second bracket 31 is larger than the The first bracket 30 is long.

[0036] The municipal shield tunnel of the present invention p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com