Threaded-connection conical seal head

A threaded connection, conical head technology, applied in pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of difficult maintenance and non-removal of the head, to facilitate disassembly and maintenance, improve sealing performance and safety performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

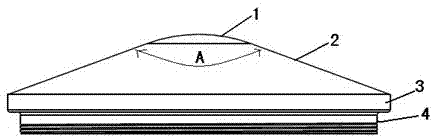

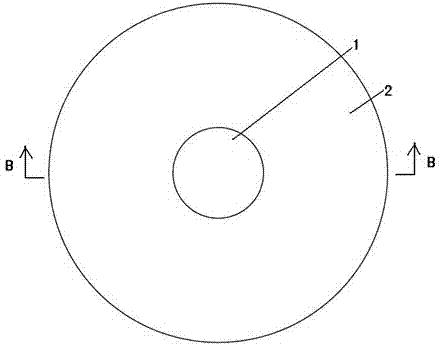

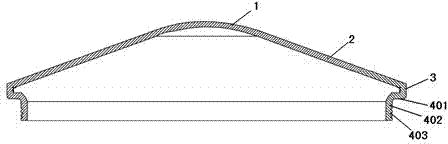

[0020] Referring to Figure 1, figure 2 , image 3 and Figure 4 As shown, the present invention is a threaded conical head, including a head body and a threaded connection device 4 arranged at the lower end of the head body;

[0021] In this embodiment, the head body includes a conical seal body 2, a head cover 1 and a cylindrical seal body 3, the upper end of the conical seal body 2 is connected to the head cover 1, and the lower end is connected to the cylindrical seal body 3;

[0022] In this embodiment, the threaded connection device 4 includes a first connecting body 401 and a second connecting body 402. One end of the first connecting body 401 is connected to the cylindrical seal body 3, the other end is connected to the second connecti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap