Flow rate measuring device for circulating liquid

A flow measurement device and a technology for circulating liquid, which are applied in the measurement field, can solve the problem of low measurement accuracy, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

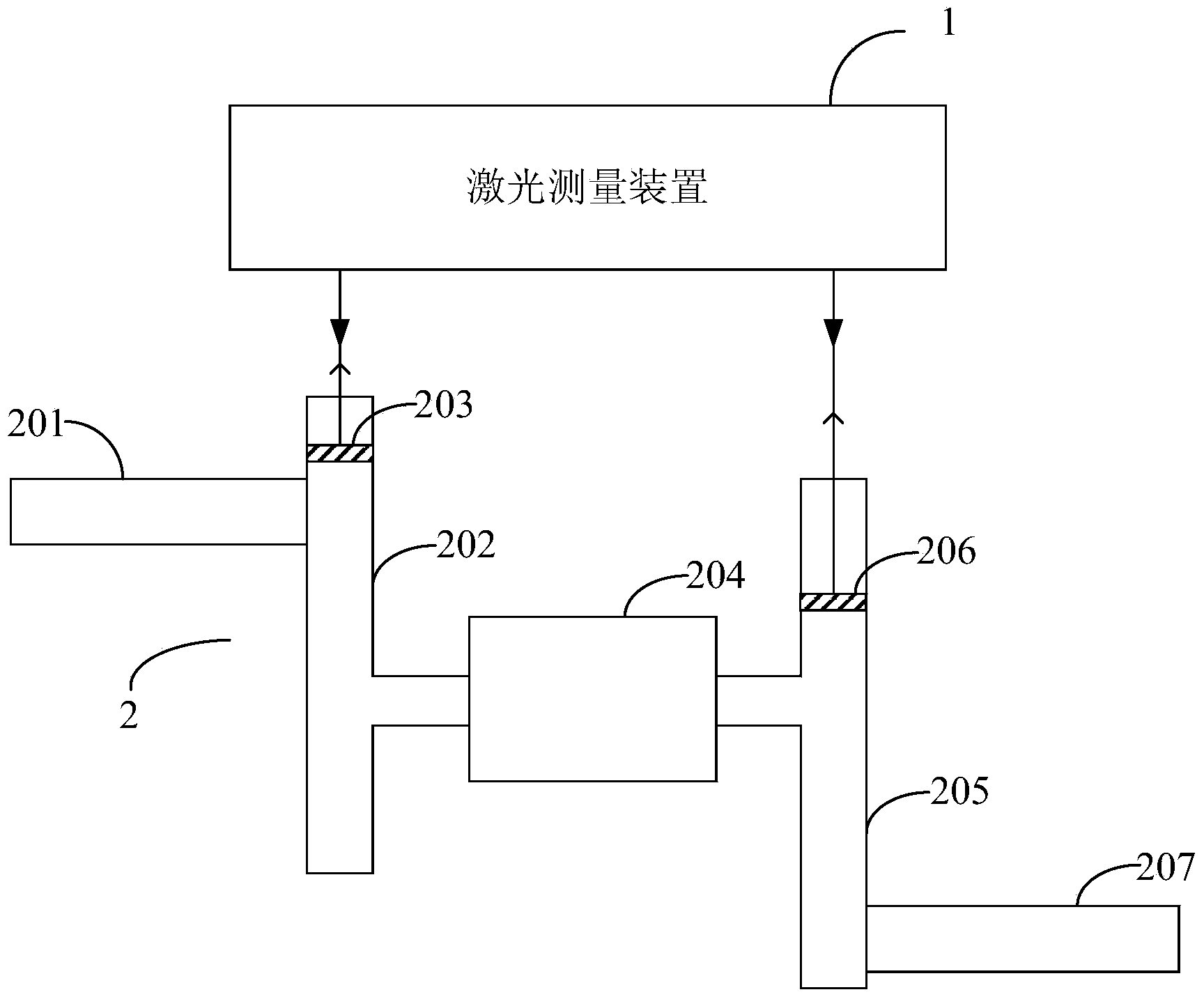

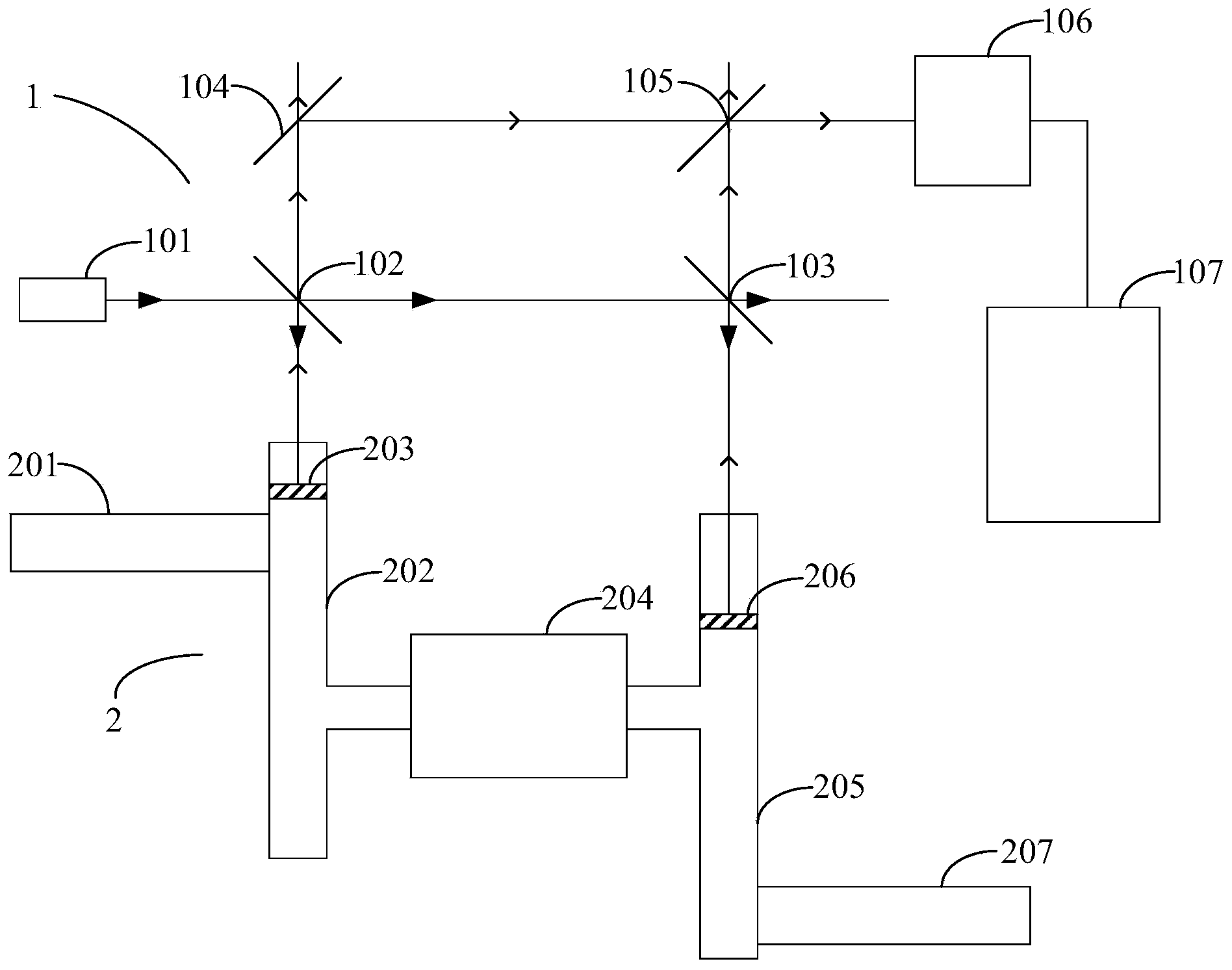

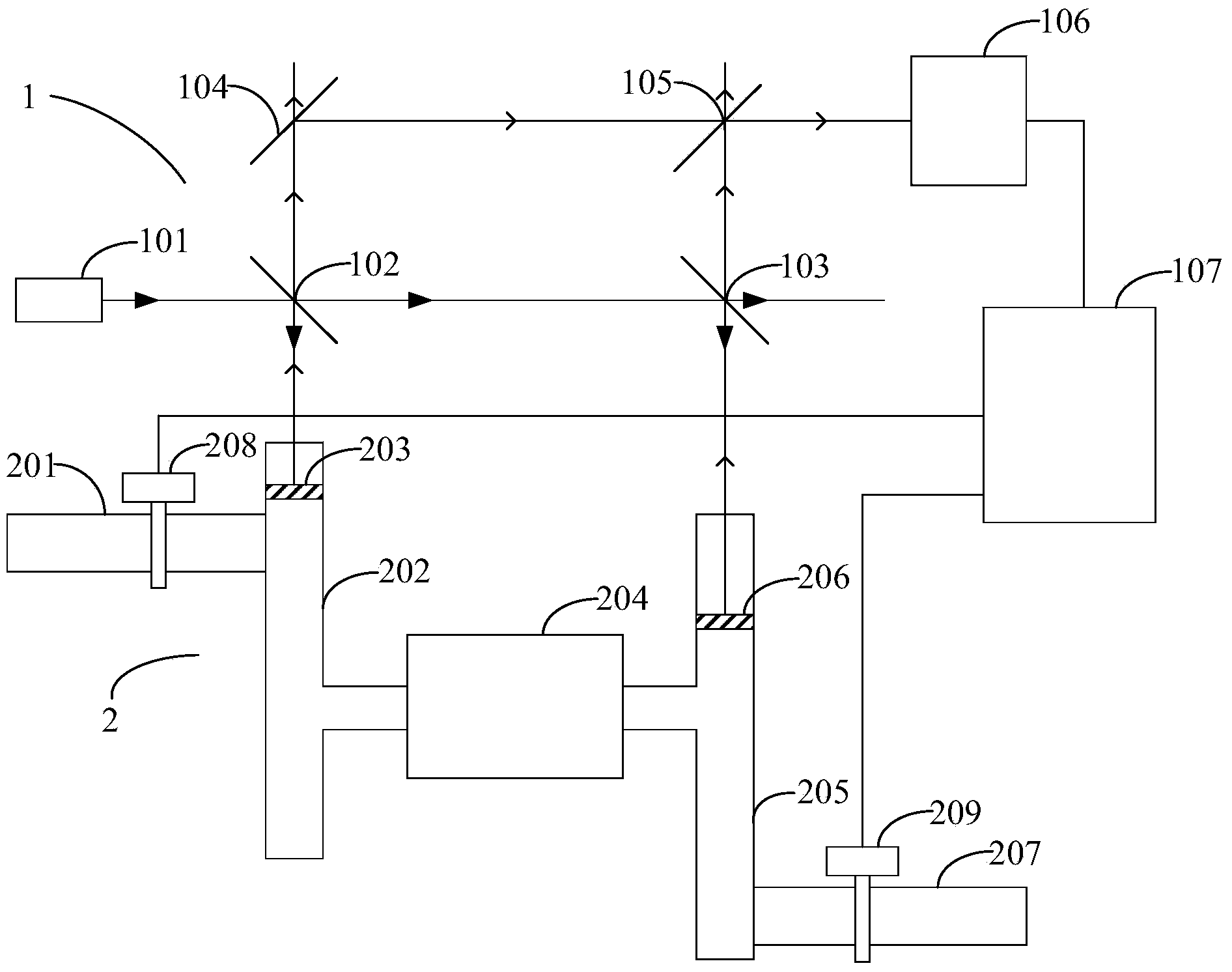

[0030] figure 1 It is a structural schematic diagram of Embodiment 1 of the circulating liquid flow measurement device of the present invention. Such as figure 1 As shown, the device of this embodiment may include: a laser measuring device 1, a load cooling device 2;

[0031] The load cooling device 1 includes: a liquid inlet pipe 201, a liquid inlet buffer 202, a liquid inlet reflective floating pad 203, a load 204, a liquid outlet buffer 205, a liquid outlet reflective floating pad 206, and a liquid outlet pipe 207; wherein,

[0032] The liquid inlet pipe 201 is connected with the liquid inlet buffer 202;

[0033] The liquid inlet buffer 202 is connected to the load 204 through the load liquid inlet;

[0034] The load 204 is connected to the liquid outlet buffer 205 through the load liquid outlet;

[0035] The liquid outlet buffer 205 is connected to the liquid outlet pipe 207;

[0036] The liquid-inlet reflective floating pad 203 is arranged in the liquid-inlet buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com