A torsional fatigue test method for arc springs in a dual-mass flywheel structure

A dual-mass flywheel and test method technology, applied in the field of arc spring torsional fatigue test device, can solve the problem of not being able to meet the detection requirements of arc spring, and achieve the effects of safe use, convenient operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

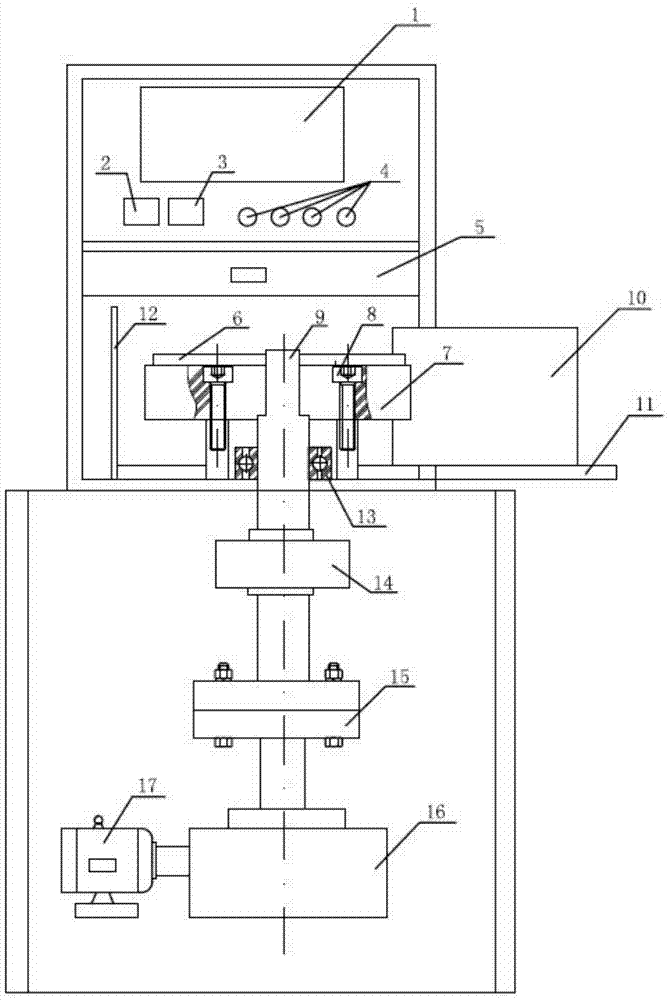

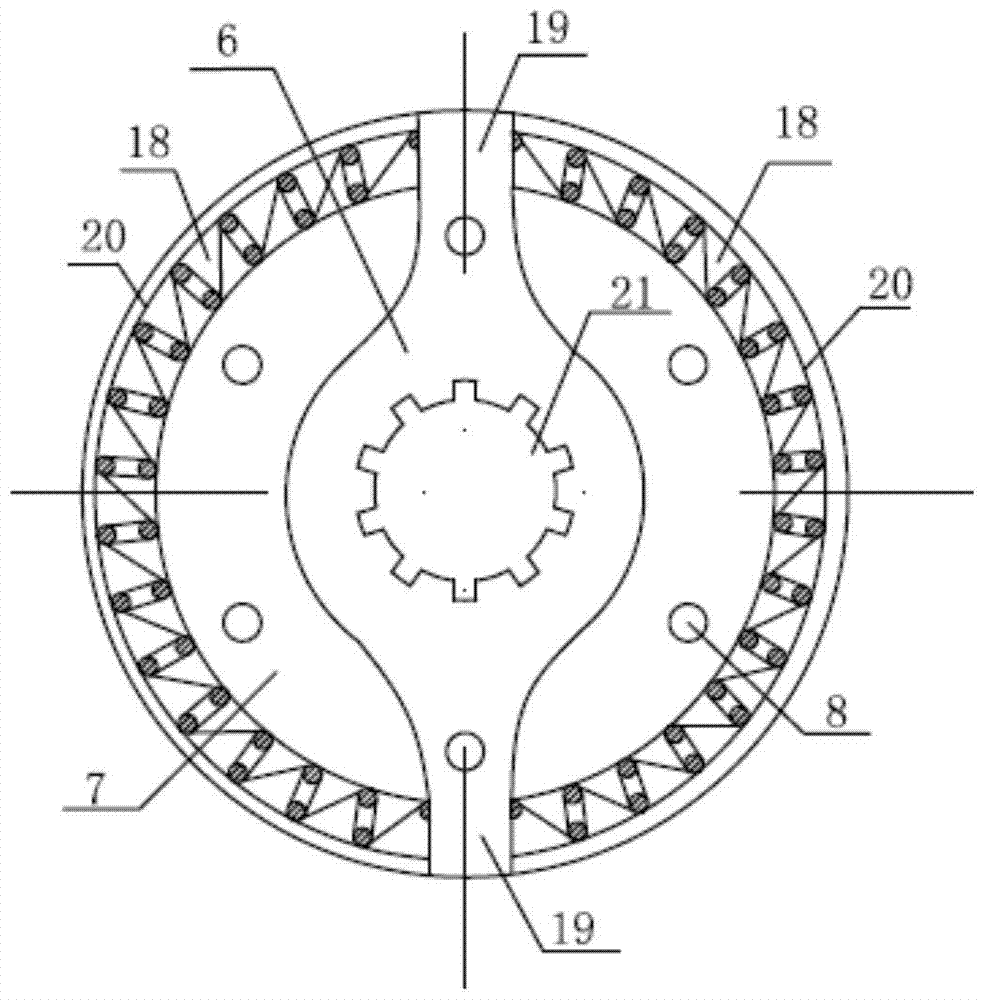

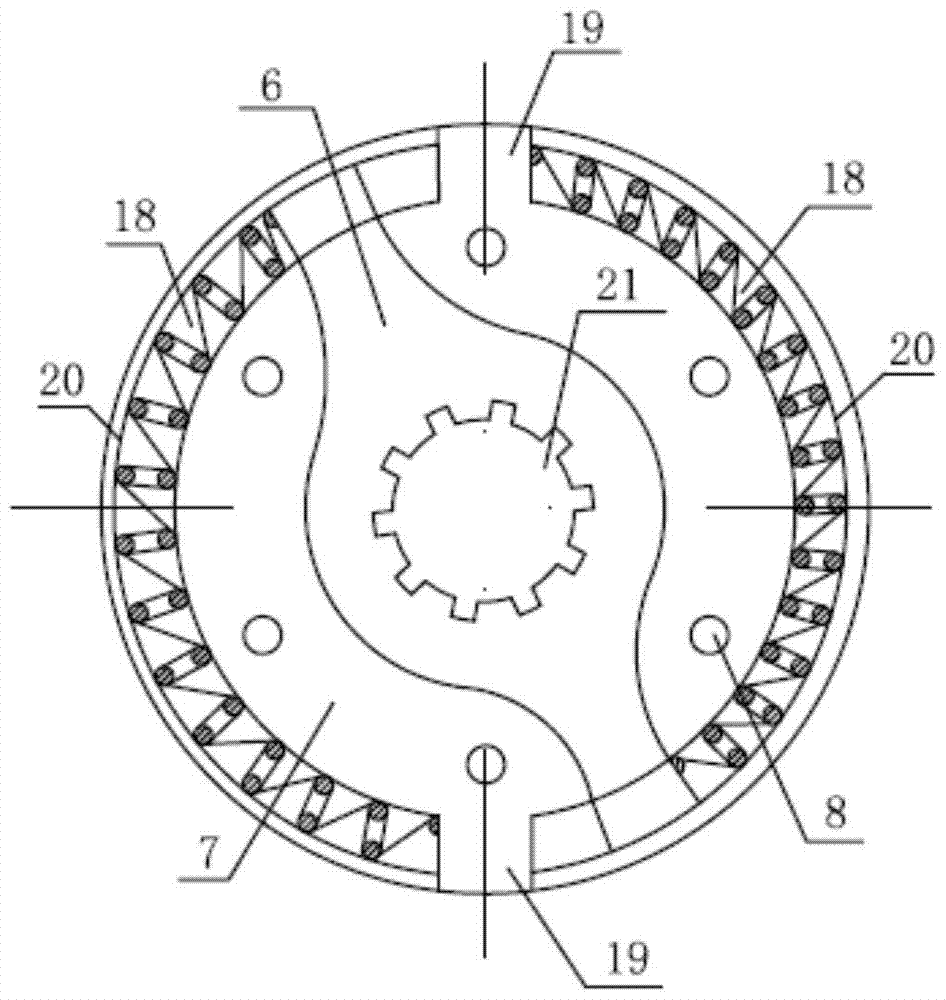

[0028] see figure 1 , Figure 2a and Figure 2b , in the present embodiment, set up and constitute the constant torque / fixed angle arc spring torsional fatigue test device in the following form: the arc spring detection mold 7 is set, and the arc slideway 20 that is opposite to the two openings constitutes a loop. The two ends of the arc-shaped slideway 20 are respectively provided with stoppers 19, the height of the top surface of the stoppers 19 and the arc-shaped slideway 20 is the same, and the arc-shaped spring 18 placed in the arc-shaped slideway 20 is in a non-compressed state Clamped between the stoppers 19 at both ends, and half of the height of the arc spring 18 is submerged in the arc slideway 20, and the other half is protruding from the top surface of the arc slideway; The arc spring detection mold 7 is fixed on the test bench by countersunk head screws 8; a rotatable torsion disk 6 is arranged at the center of the arc spring detection mold 7, and the torsion di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com