Driver Controller Test System and Its Test Method

A driver controller and test system technology, applied in electrical testing/monitoring, etc., can solve the problems of inability to detect multiple handles, incapable of continuous automatic movement, inability to switch loads, etc., to achieve convenient viewing and printing, accurate and reliable load access , good effect of human-machine interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

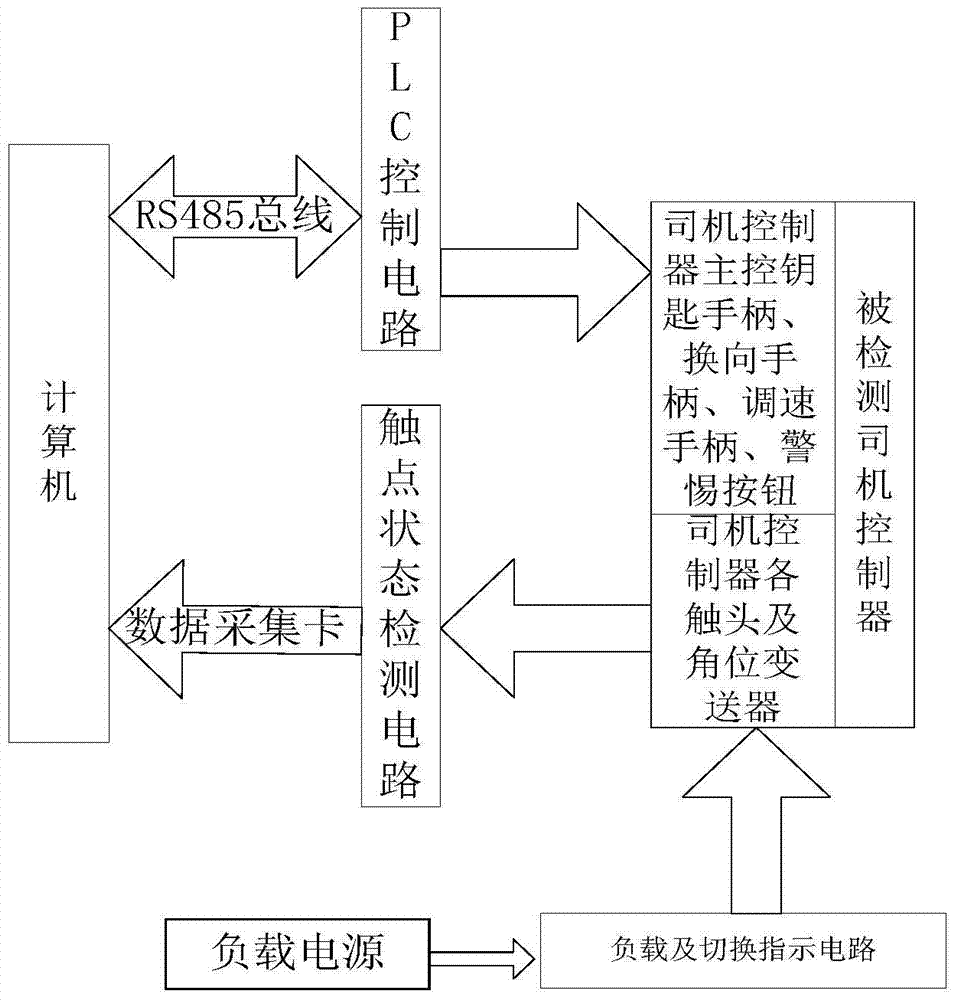

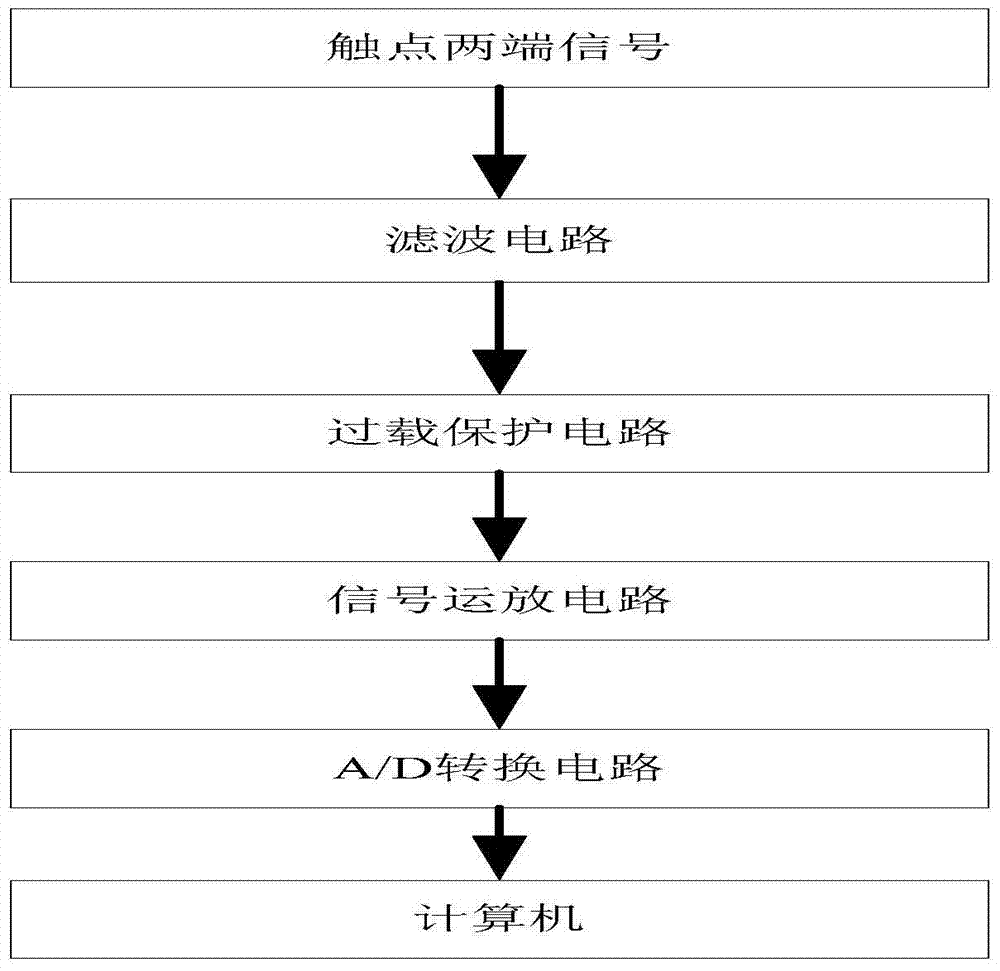

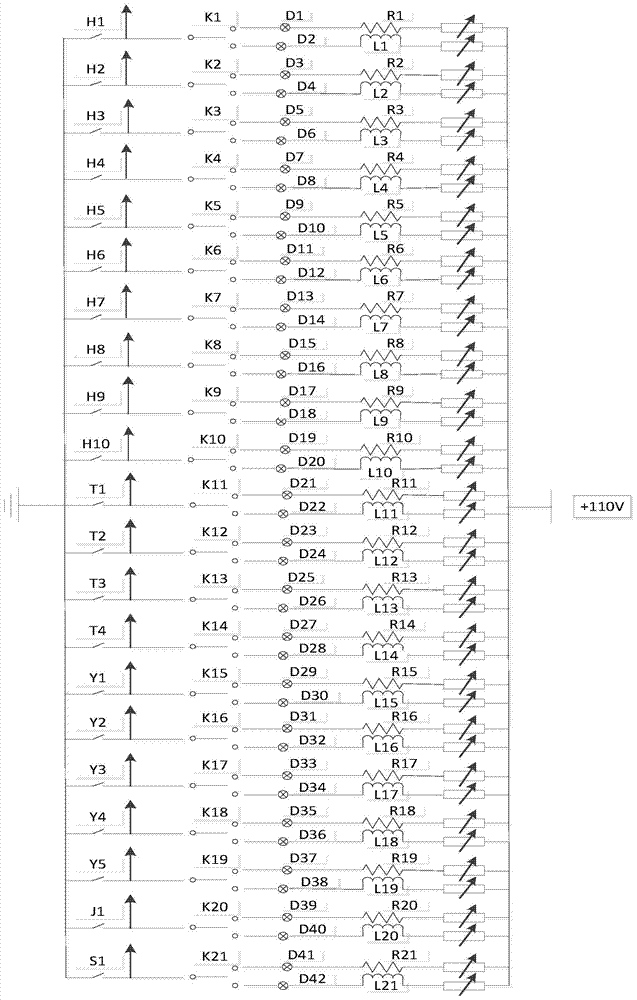

[0068] according to the above figure 1 , figure 2 , Figure 3(a), Figure 3(b), Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 The embodiment constitutes the driver controller test system used in this embodiment, adopts this system to test the contact contact performance and angle positioner current output performance test of the tested driver controller, and the tested driver controller includes 21 pairs of contacts and 1 Angle transmitter, the load is resistive load or inductive load, the operation steps are:

[0069] The first step is to double-click the "Test Program" icon to enter the login interface, enter the company name and operator name in the input box, and click the "Enter System" button to enter the system;

[0070] The second step is to enter the running main interface:

[0071] The operation mode of the main interface is: click the "Initialize" button, the interface will prompt whether it is in the initial position, and a paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com