Multi-position car body assembly process-oriented online multiple-deviation source diagnosing system and method

An assembly process and diagnostic system technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as limited application, failure to obtain failure modes, confusion, etc., to achieve out-of-tolerance diagnosis and improve the utilization of diagnostic knowledge rate and diagnostic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

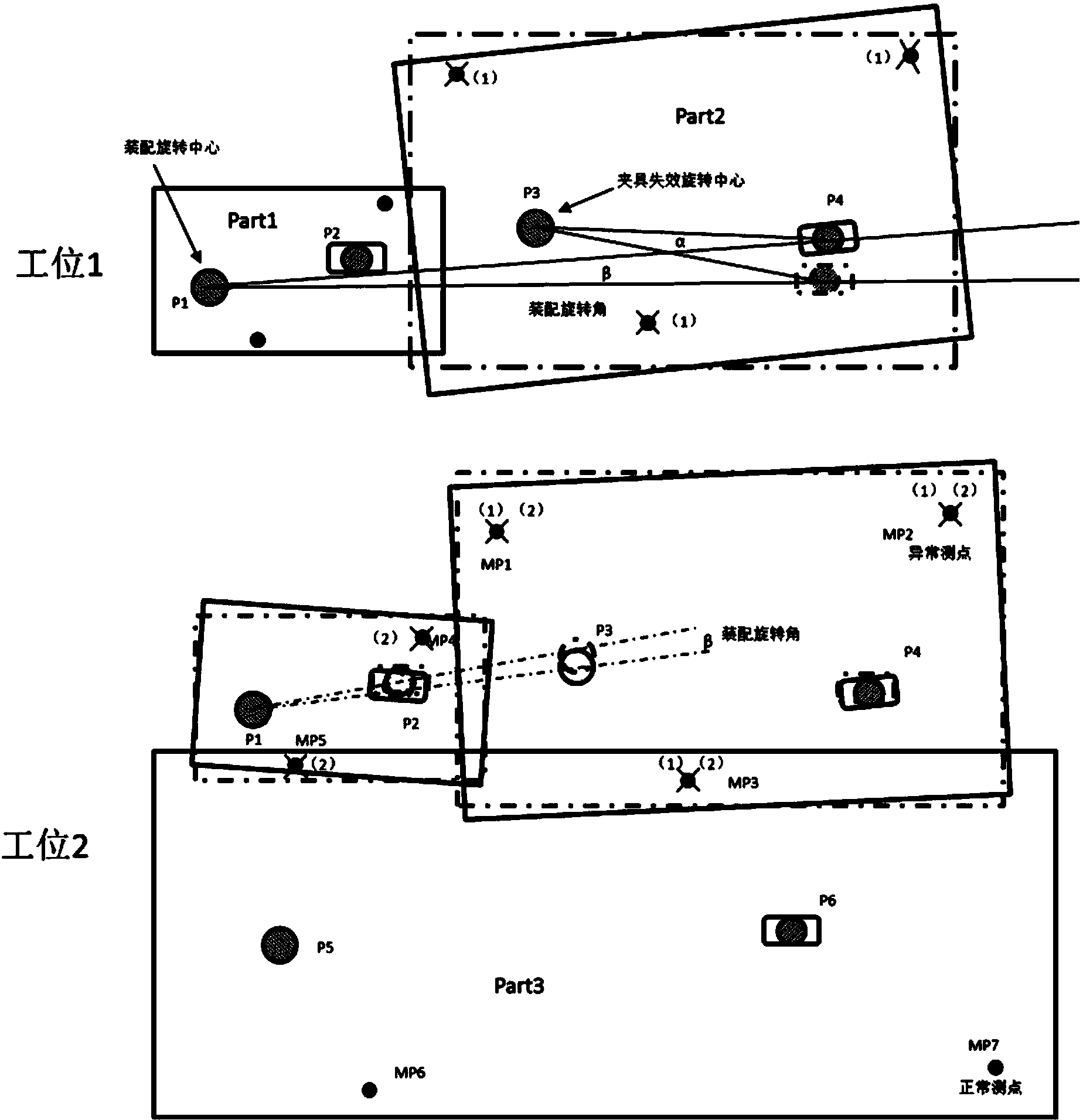

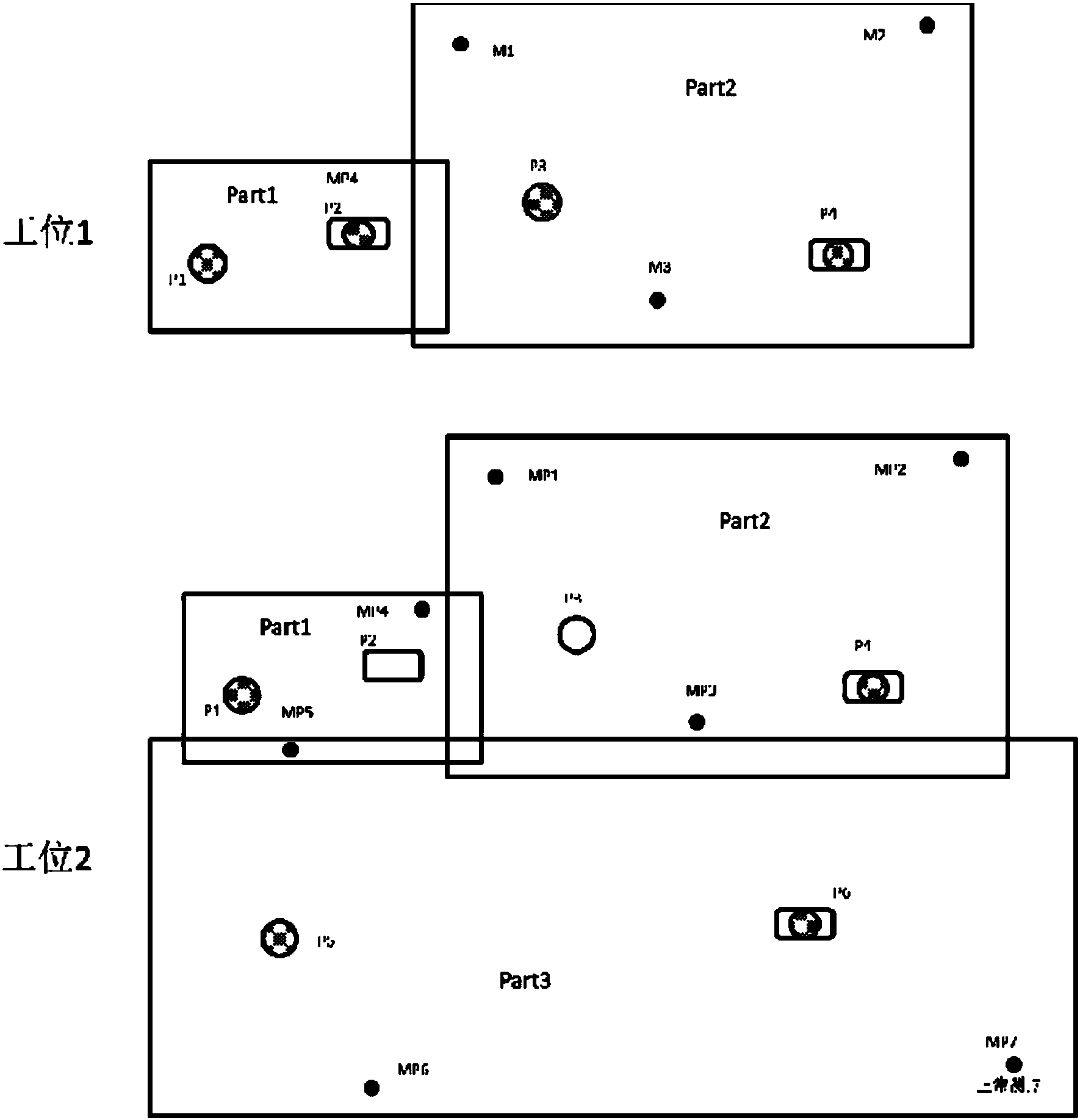

[0035] Such as Figure 6 As shown, the multi-deviation source online diagnosis system oriented to the multi-station assembly process of the car body of the present invention includes a fixture failure mode space calculation module, which is used to realize the calculation of the single-station potential fixture failure mode and the calculation of the multi-station fixture failure mode ; The multi-source heterogeneous data processing module is used to realize the projection and calculation of the detection data on the pattern space; the identification and diagnosis module of the deviation source under the multi-station is used for the online diagnosis of the deviation source under the multi-station.

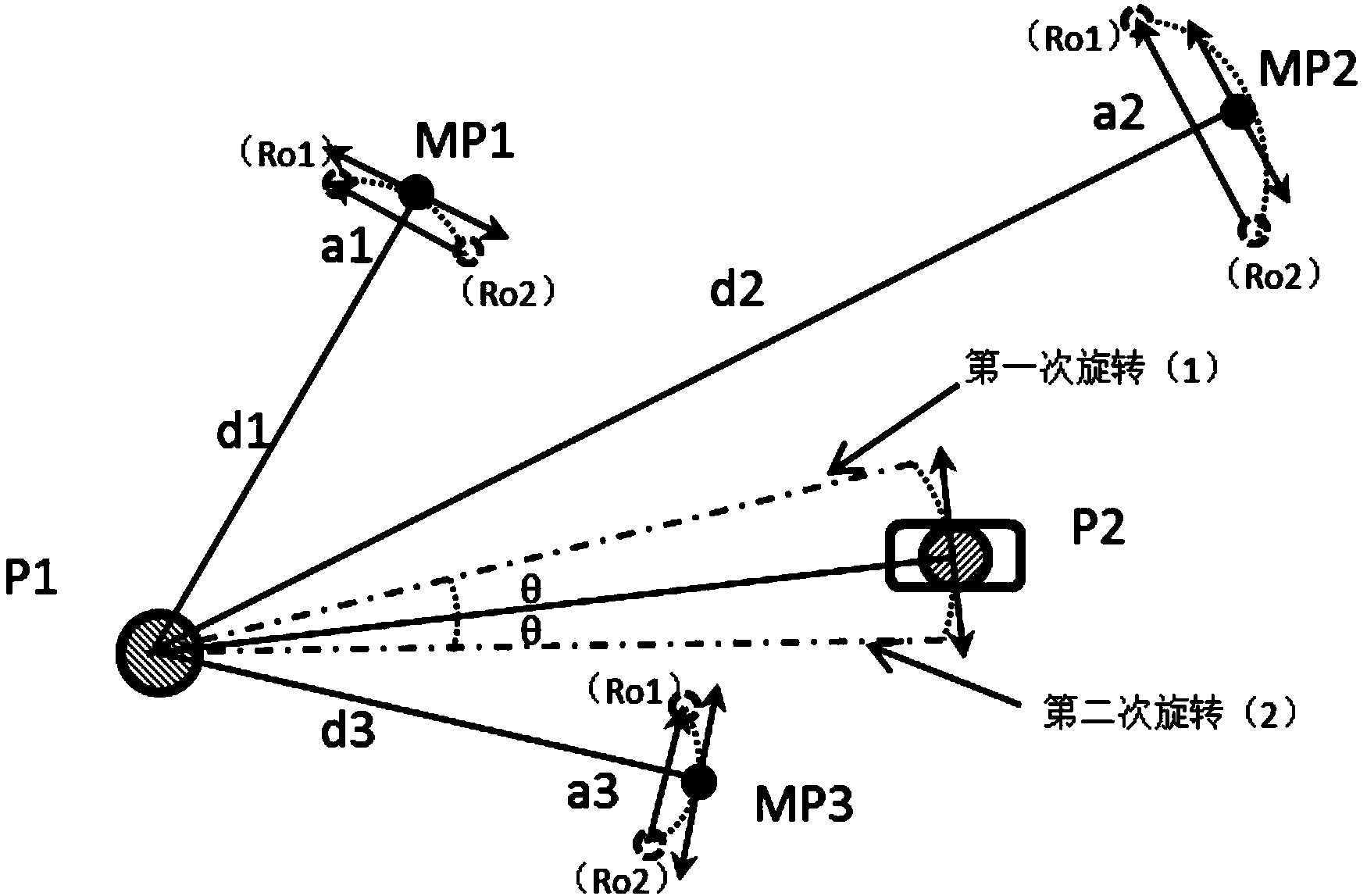

[0036] The method for on-line diagnosis of multi-deviation sources facing the multi-station assembly process of the vehicle body according to the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com