On-line diagnosis method of vehicle body assembly quality based on part posture relationship discrimination

A technology of pose relationship and diagnosis method, applied in the fields of motor vehicles, transportation and packaging, can solve the problems of multiple deviation sources and difficult diagnosis of multiple deviation sources, and achieve the effect of reducing loss and improving the accuracy of diagnosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

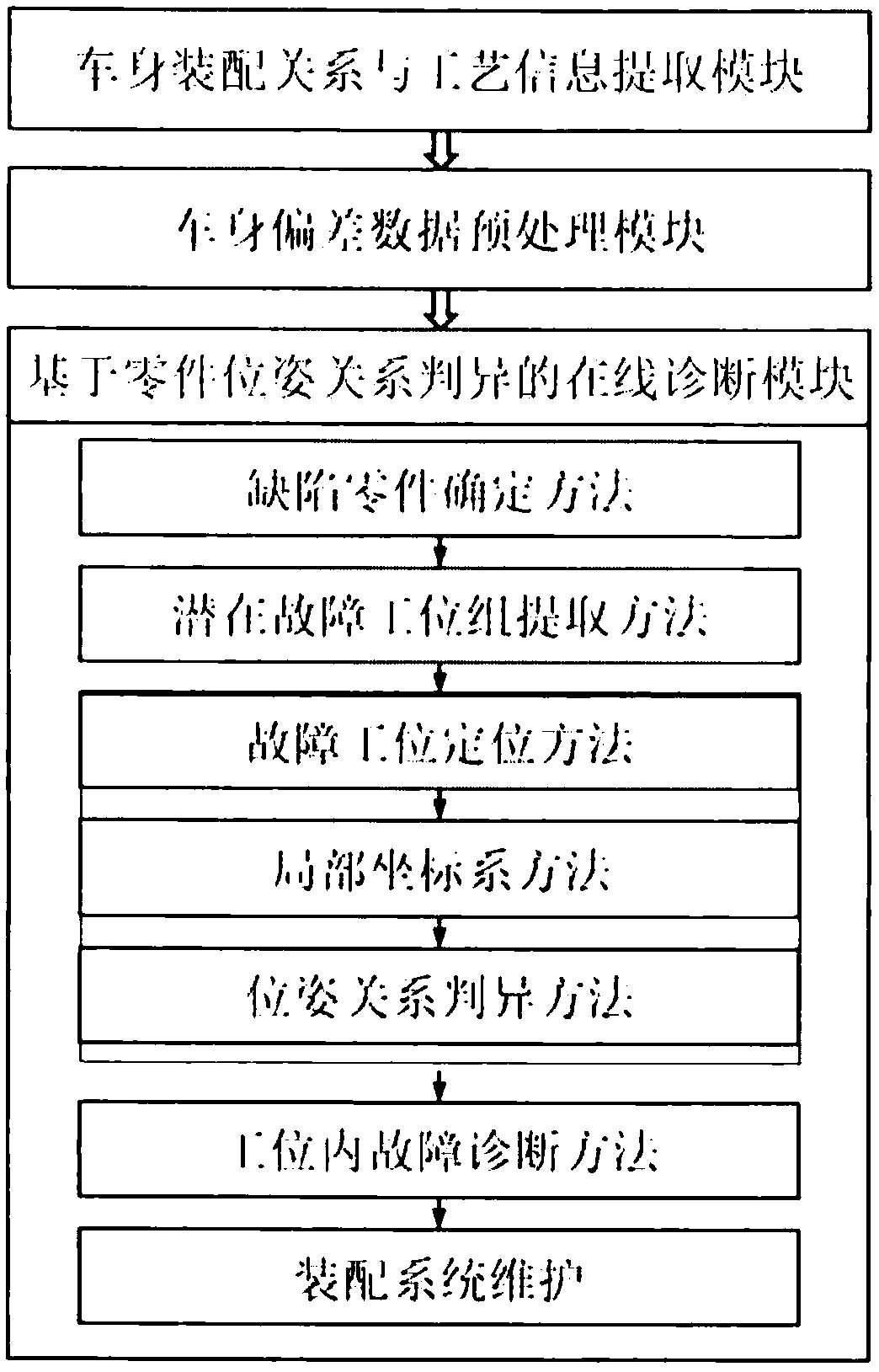

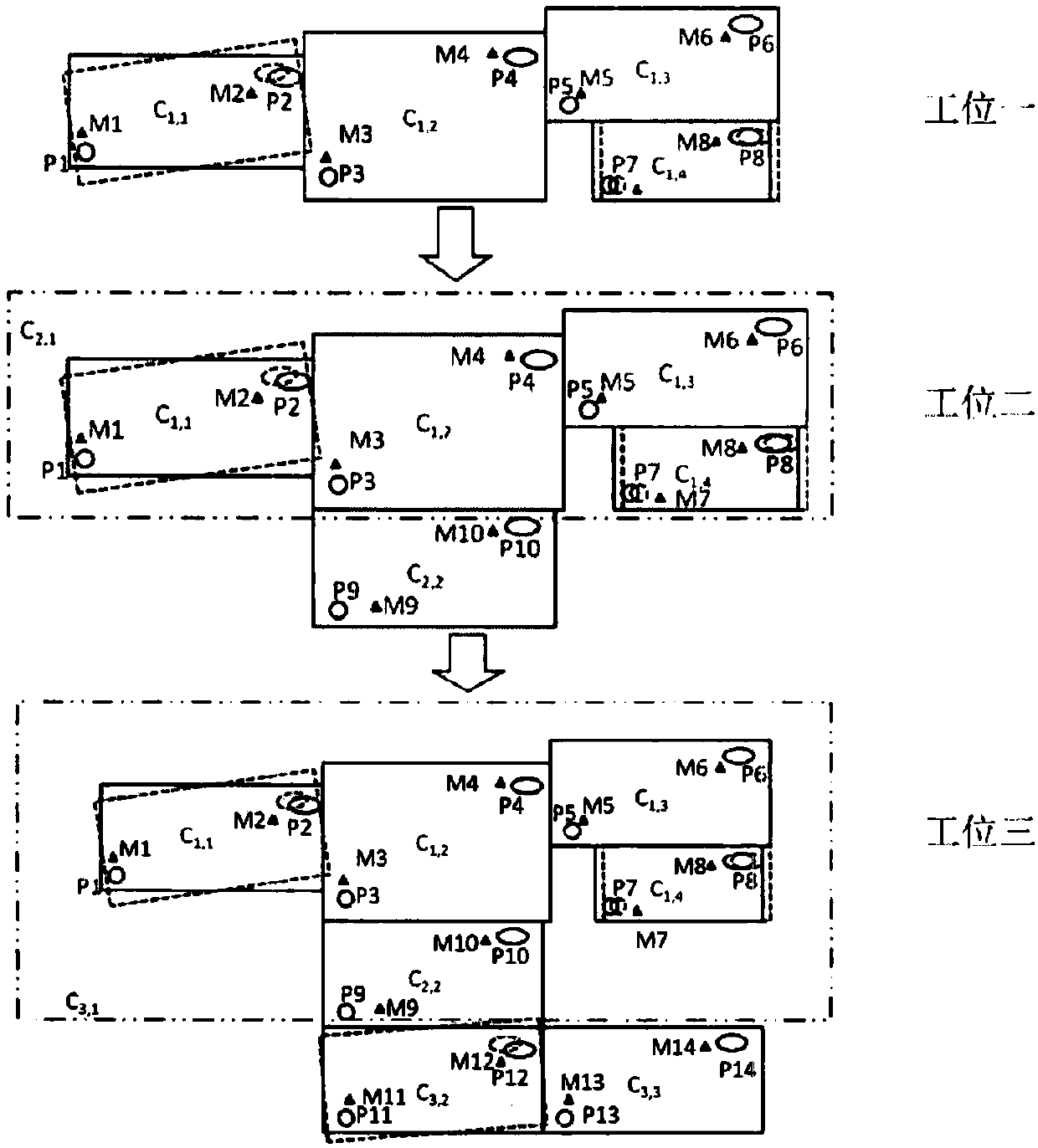

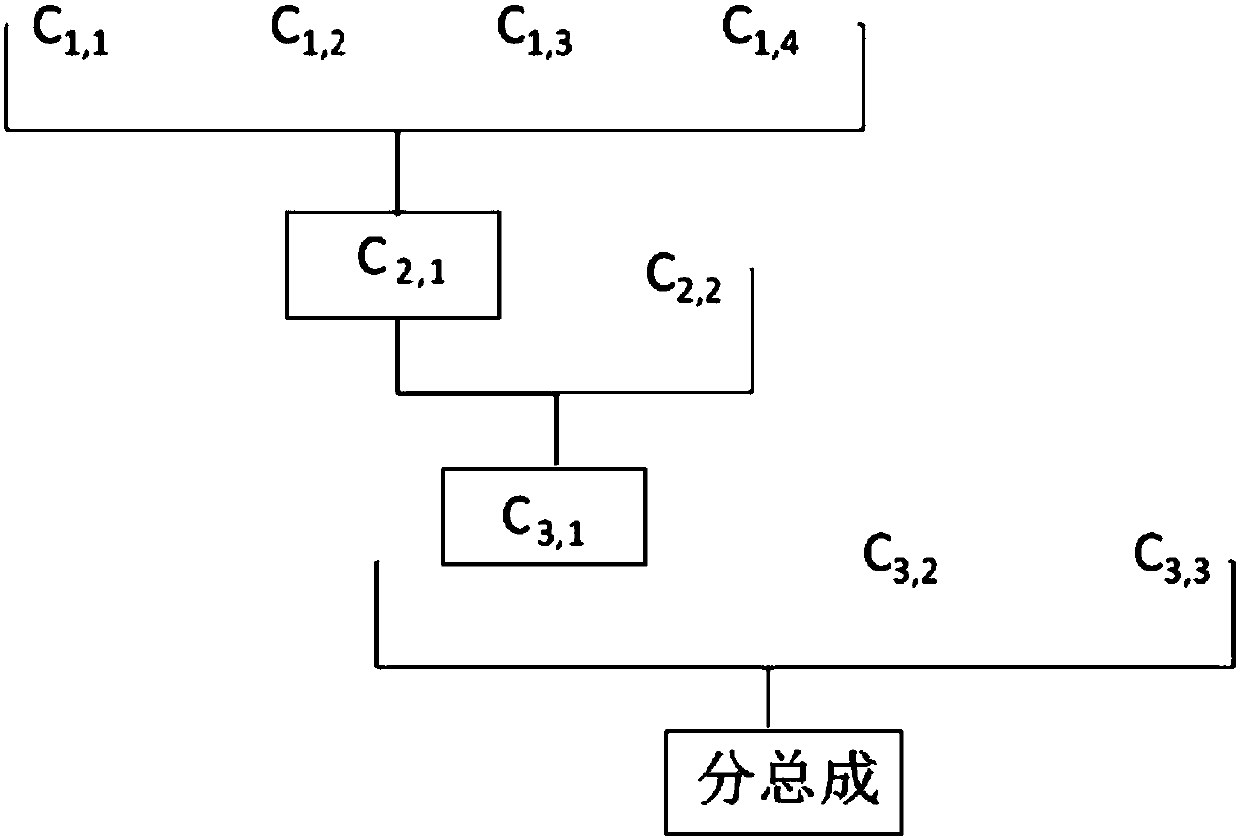

[0024] The car body assembly quality online diagnosis system includes a car body assembly relationship and process information extraction module, which is used to record the process information of the assembly process and realize the matching of all the stations designed for faulty parts; the body deviation data preprocessing module is used to measure the three-coordinate instrument The obtained car body end data is preprocessed, the fluctuating measuring points are extracted, and the measuring points are corresponding to the corresponding parts and the related stations; the online diagnosis module based on the position and posture of the parts is used to realize the fault station of the white body and the station. Diagnose and analyze the causes of failures and guide the formulation of maintenance strategies.

[0025] Such as figure 1 As shown, the specific steps of the method for on-line diagnosis of car body assembly quality based on the discrimination of the part pose relatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com