A kind of over-temperature protection method and device

An over-temperature protection, real-time temperature technology, applied in emergency protection circuit devices, emergency protection devices with automatic disconnection, circuit devices, etc., can solve the problems of over-temperature burning of IGBT modules and the inability of temperature sensors to reflect the temperature at the wafer in real time. , to avoid the effect of over-temperature burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

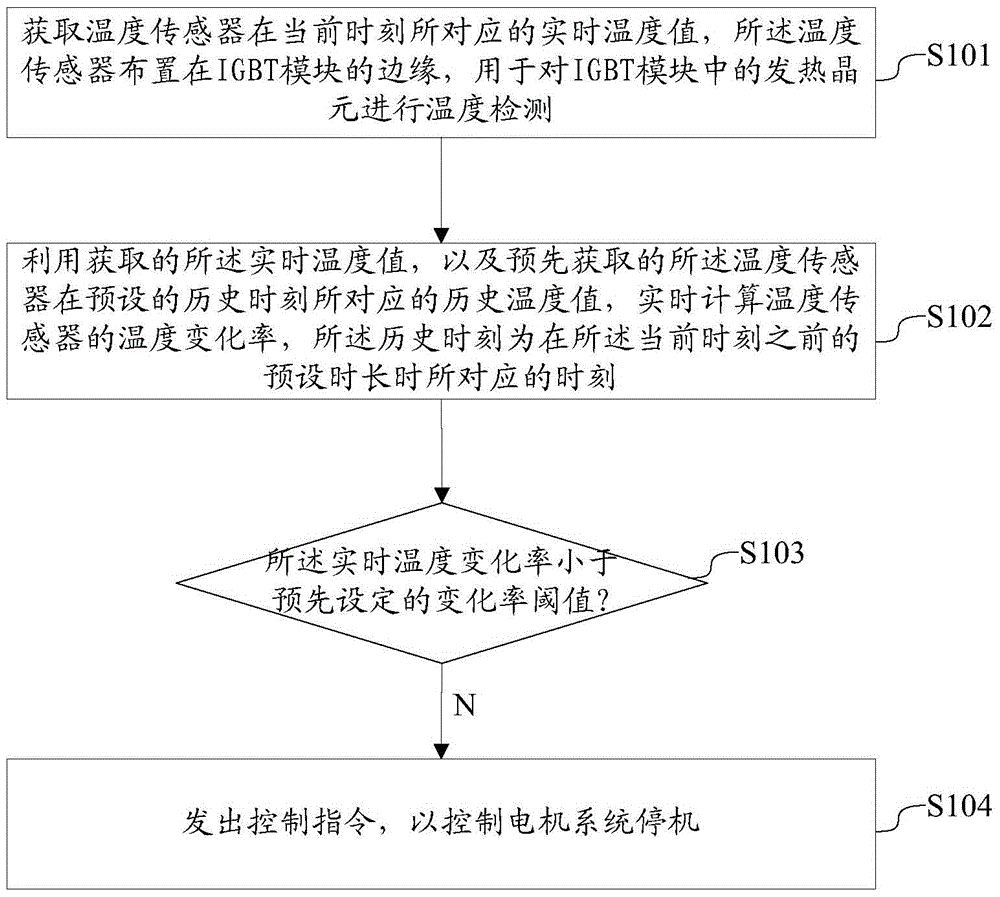

[0035] This embodiment 1 discloses an over-temperature protection method, which is used for over-temperature protection of the IGBT module when the cooling system is abnormal, refer to figure 1 , the method may include the following steps:

[0036] S101: Obtain a real-time temperature value corresponding to a temperature sensor at the current moment, the temperature sensor is arranged on the edge of the IGBT module, and is used to detect the temperature of the heating element in the IGBT module.

[0037] The applicant has found through research that when the temperature of the IGBT crystal element rises rapidly due to an abnormal cooling system, although the real-time temperature of the temperature sensor is much lower than the crystal element temperature of the IGBT at the same time, the temperature of the sensor will change with the crystal element temperature. The synchronous rapid rise is much greater than the temperature change rate of the sensor when the cooling system i...

Embodiment 2

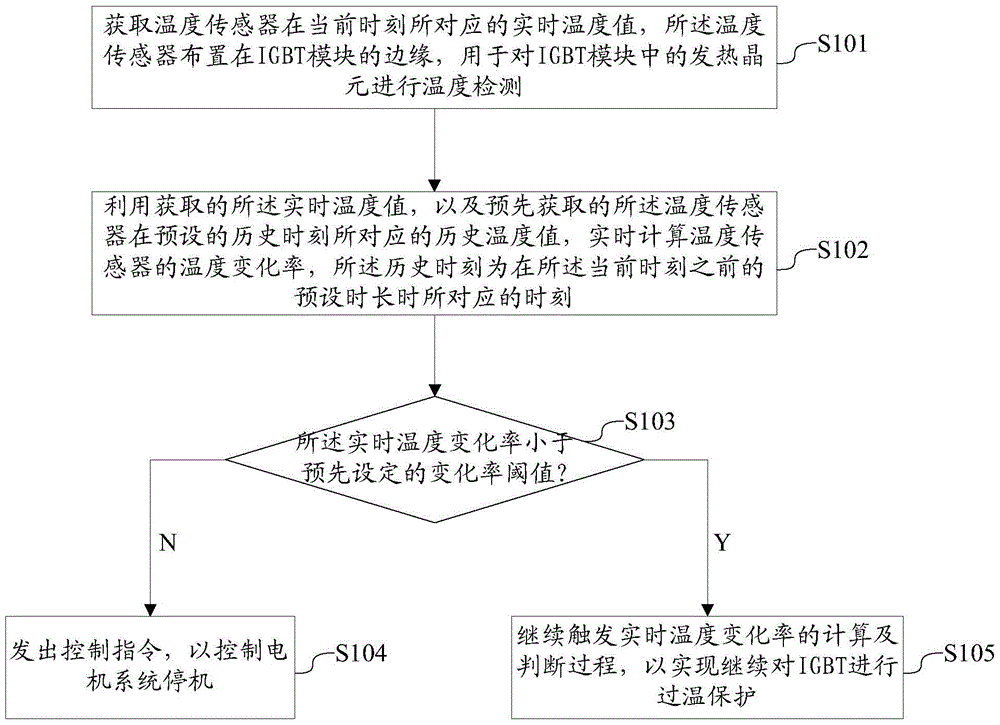

[0060] In the second embodiment, refer to image 3 , the over-temperature protection method also includes the following steps:

[0061] S105: If the judgment result is yes, continue to trigger the calculation and judgment process of the real-time temperature change rate, so as to continue to perform over-temperature protection on the IGBT.

[0062] That is, in this embodiment, if k正 +k 异 ) / 2, it means that the temperature change of the temperature sensor and the heating element in the IGBT is relatively stable, so the heat dissipation of the IGBT is normal, and the cooling system has no abnormality. In this case, the motor is not triggered to stop, and the temperature change of the temperature sensor continues The rate is detected to realize the real-time over-temperature protection of the IGBT module.

Embodiment 3

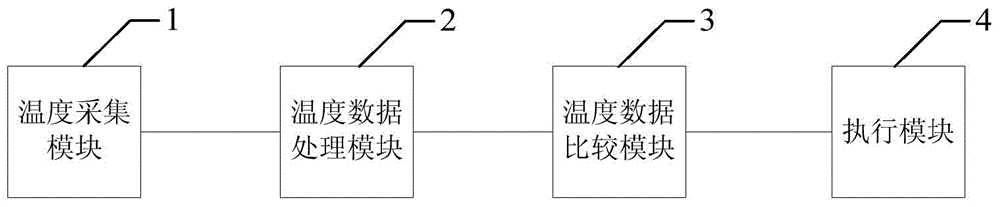

[0064] Embodiment 3 discloses an over-temperature protection device, which corresponds to the over-temperature protection method disclosed in Embodiment 1 and Example 2.

[0065] First, corresponding to Embodiment 1, refer to Figure 4 , the device includes an acquisition module 100 , a calculation module 200 , a judgment module 300 and a first protection module 400 .

[0066] The obtaining module 100 is used to obtain the real-time temperature value corresponding to the temperature sensor at the current moment, and the temperature sensor is arranged on the edge of the IGBT module, and is used to detect the temperature of the heating element in the IGBT module.

[0067] The calculation module 200 is configured to calculate the real-time temperature change rate of the temperature sensor by using the acquired real-time temperature value and the pre-acquired historical temperature value corresponding to the temperature sensor at a preset historical moment, and the historical mome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com