A load control method for a belt conveyor

A belt conveyor and load control technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of unsatisfactory results, low reliability and low precision, and achieve low cost, Improved security and high real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

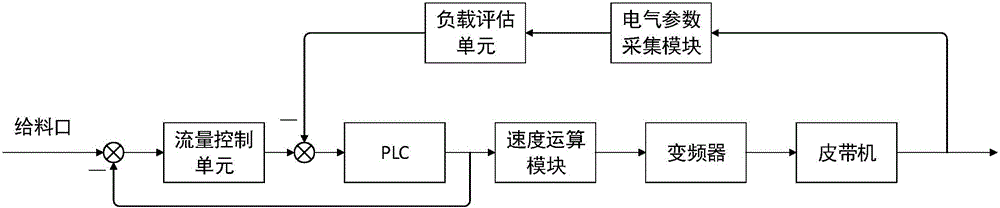

[0036] The system of the present invention is as figure 2 As shown, it includes PLC controller, speed calculation module, electrical parameter acquisition module, load evaluation module, A / D conversion module, and flow control unit. Such as Figure 4 As shown, the specific process is as follows:

[0037] 1. When the belt conveyor is working normally, use the multifunctional smart meter (ACR320E) in the electrical parameter acquisition module to collect the voltage and current of the three-phase motor, and measure the power factor, active power and reactive power, and then through the RS-485 interface Enables communication with the load evaluation unit.

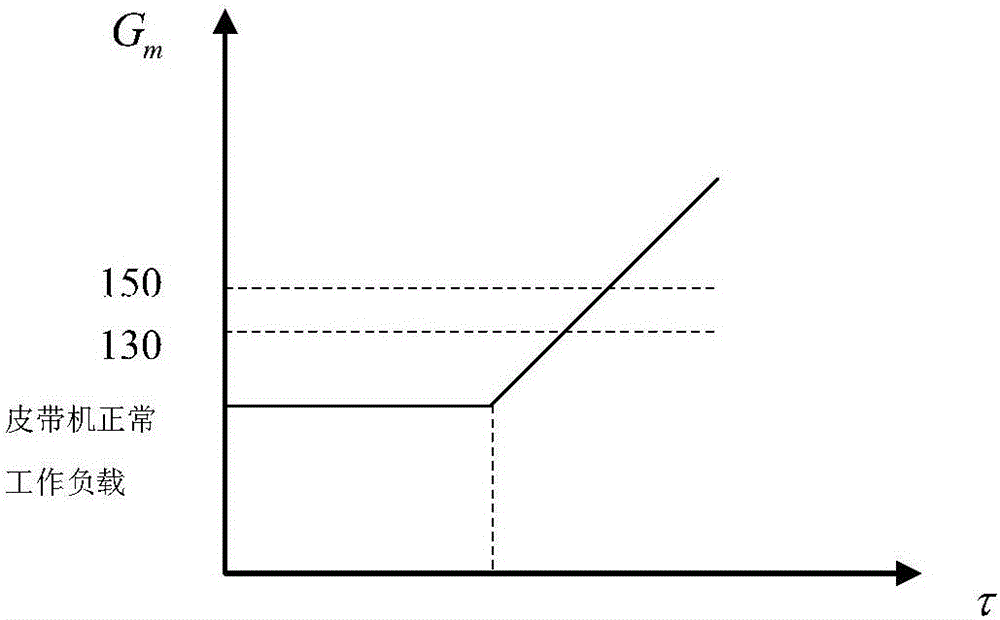

[0038] 2. The load evaluation unit first calculates the corresponding reactive power according to the rated voltage, rated current, and rated power on the motor nameplate, and uses the powerful function approximation ability of the RBF neural network algorithm to establish voltage, current, active power, and reactive power....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com