Truss type intelligent drilling equipment

A kind of drilling equipment and truss-type technology, which is applied in the field of truss-type intelligent drilling equipment, can solve problems such as inability to effectively complete the drilling process, part binding, and easy slippage, so as to avoid slippage, increase fixity, and shorten spacing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

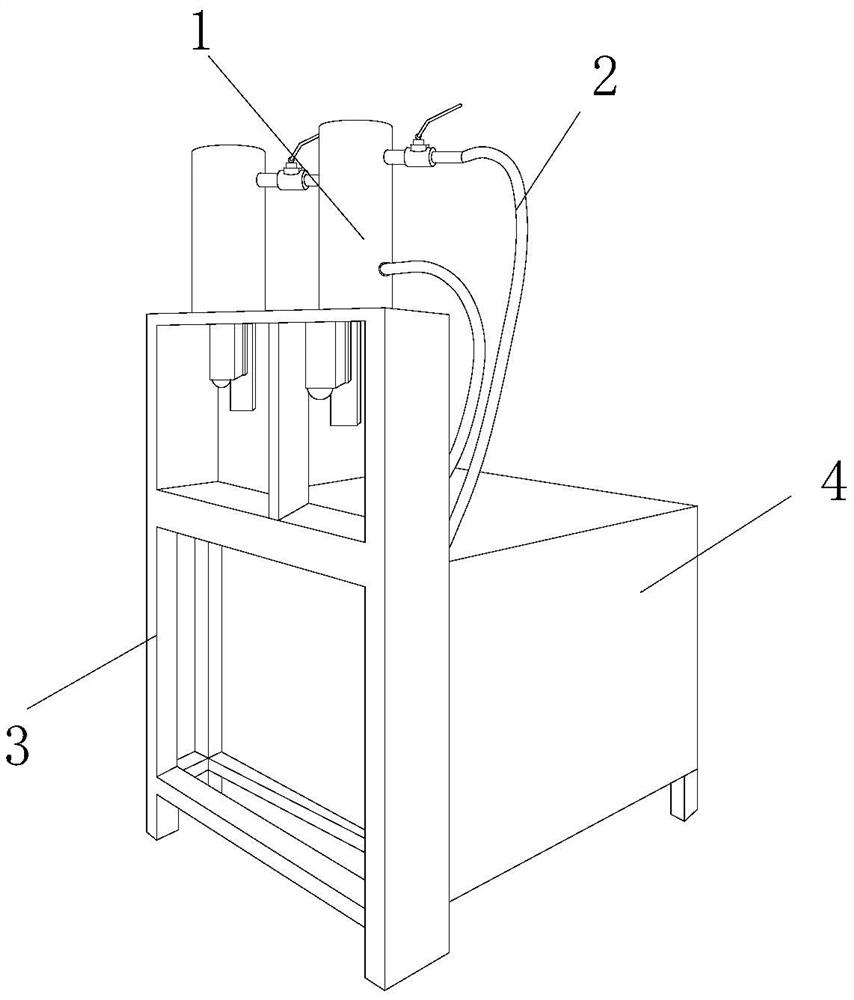

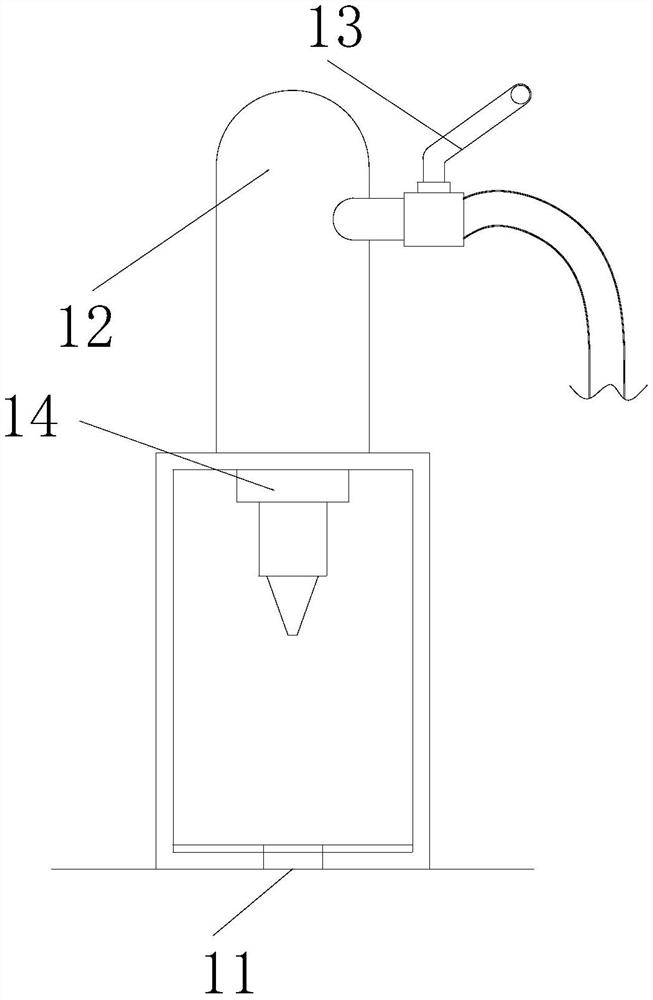

[0029] as attached figure 1 to attach Image 6 Shown:

[0030] The invention provides a truss-type intelligent drilling equipment, the structure of which includes a drilling mechanism 1, a hydraulic pipe 2, a bracket 3, and an equipment cabin 4. The drilling mechanism 1 is embedded and installed directly above the bracket 3. The hydraulic pressure The pipe 2 is nested and connected to the outer end surface of the equipment compartment 4, and the bracket 3 is fixed on the outer end surface of the equipment compartment 4 by welding, and the equipment compartment 4 is located under the right side of the drilling mechanism 1; the drilling mechanism 1 includes Place platform 11, lifting pipe 12, handle 13, and drilling tool 14. The placing platform 11 is embedded and installed directly below the drilling tool 14. The right end surface of the lifting pipe 12 is nested and connected to the hydraulic pipe 2. The handle 13 is inlaid on the upper right side of the drilling tool 14, an...

Embodiment 2

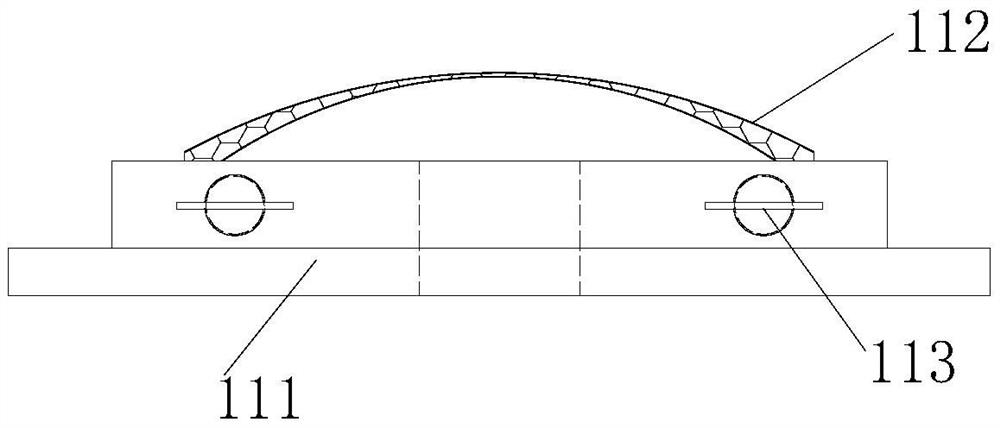

[0038] as attached Figure 7 To attach Figure 9 Shown:

[0039] Wherein, the adsorption mechanism 113 includes a ball 131, an inlay groove 132, a threaded rotating rod 133, and a knob 134. The ball 131 is movably mounted on the inner end surface of the inlaid groove 132, and the inlaid groove 132 is fixedly mounted on the threaded rotating rod. The lower end surface of the rod 133, the threaded rotating rod 133 is inlaid directly above the knob 134, the knob 134 is located directly below the inlay groove 132, and the balls 131 are arranged in two rows up and down with a distance between them, which can The rolling effect formed by the balls 131 reduces the surface friction between the embedding groove 132 and the end surface of the embedding plate 111 .

[0040] Wherein, the threaded rotating rod 133 includes a magnetic attraction mechanism 331, a rotating shaft 332, a screw blade 333, and a rotating rod 334. The magnetic attraction mechanism 331 is embedded and engaged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com