Circuit board detection device with roller compaction module with self-compaction function

A detection device and compression die technology, applied in measurement devices, material analysis through optical means, instruments, etc., can solve problems such as unclearness, affecting the accuracy of picture information, and existence of shadow areas, avoiding slippage and ensuring smoothness and the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

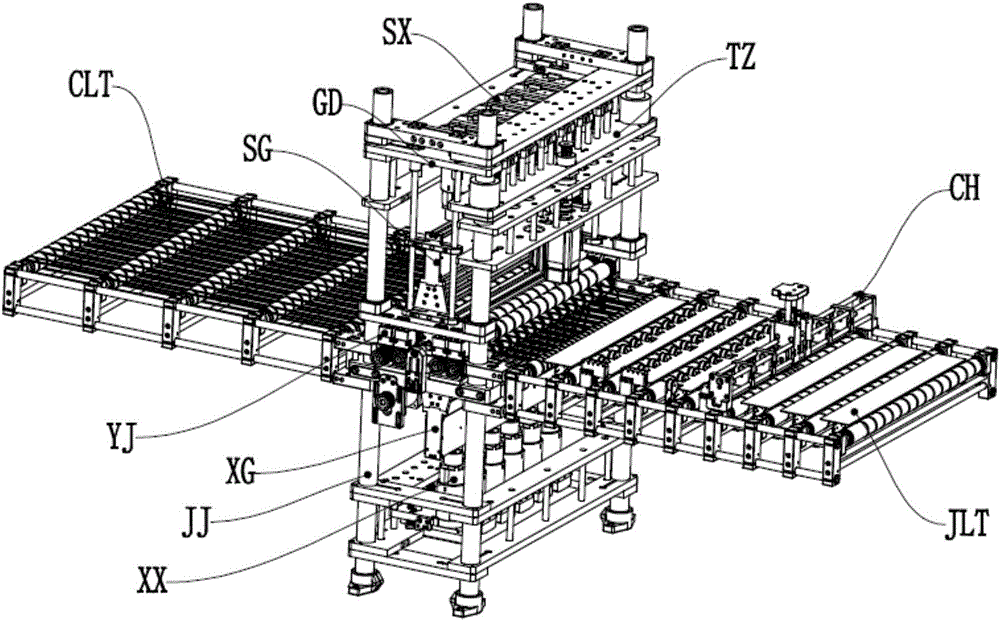

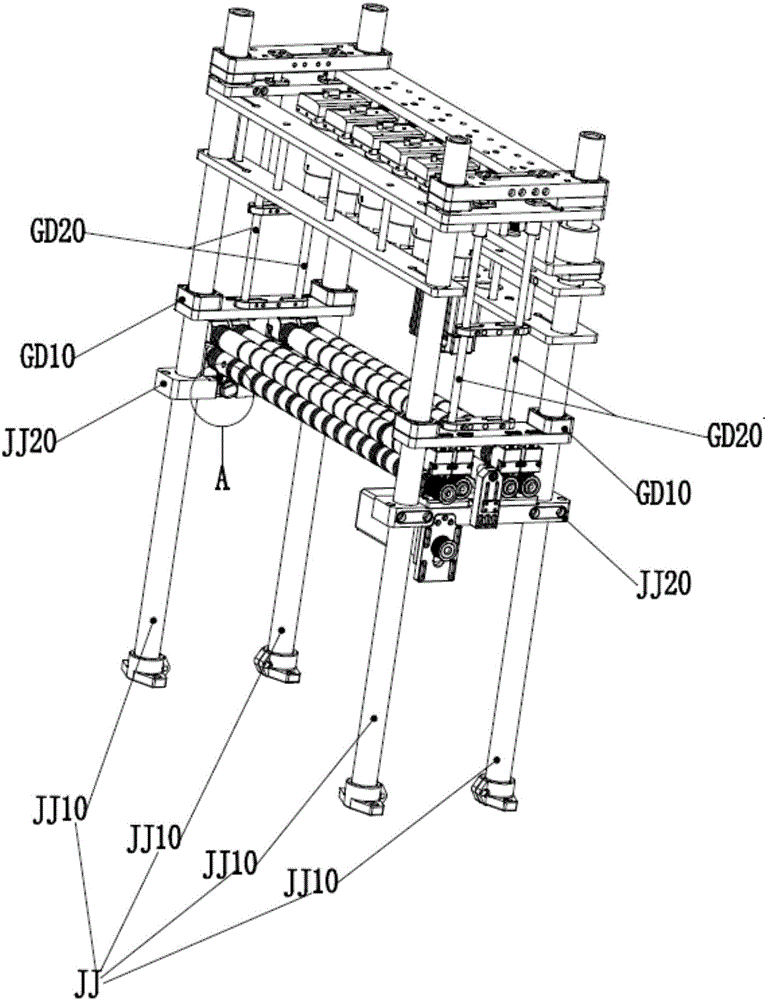

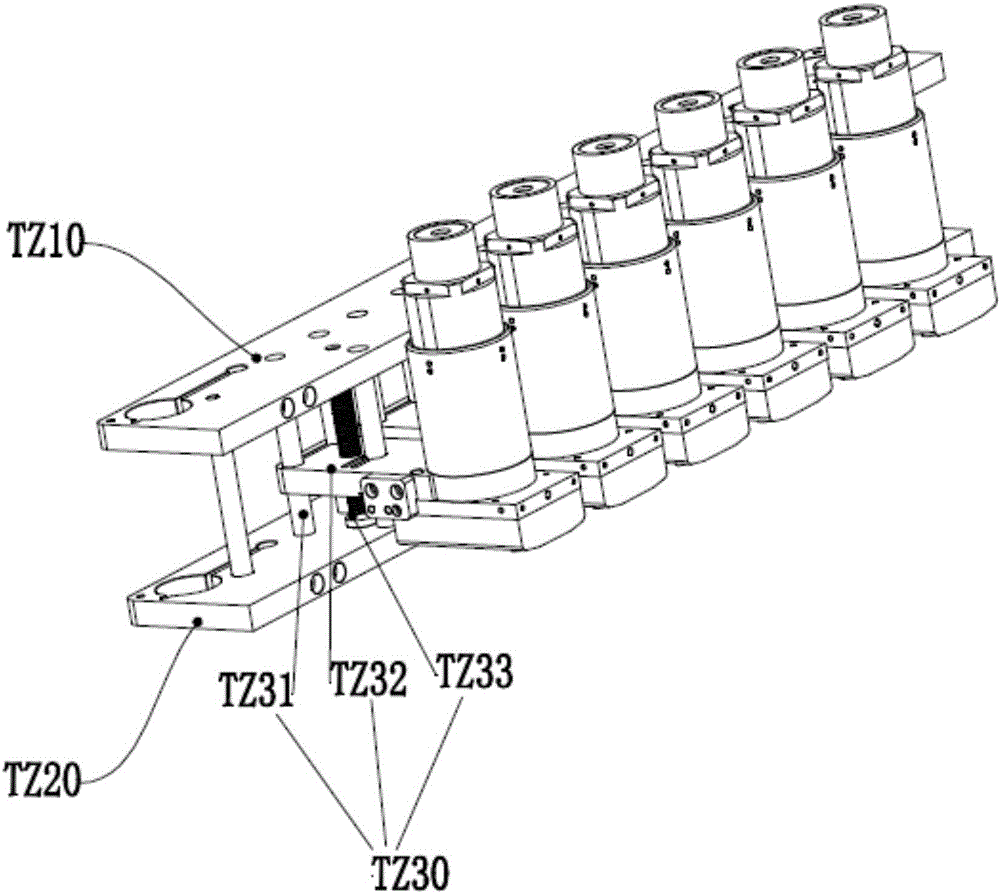

[0031] Such as Figure 1-11 As shown, a circuit board detection device with a roller pressing module having a self-pressing function, including a frame JJ, a camera module, a light source module and a roller pressing module YJ; the roller pressing module YJ A camera module and a light source module are arranged above and below the group; the frame JJ is a frame composed of no less than four columns JJ10, and the frame JJ is successively the lower camera module XX, the lower frame JJ from bottom to top. The light source module XG, the roller pressing module YJ, the upper light source module SG and the upper camera module SX; the lower light source module XG and the lower camera module XX are fixed on the frame JJ, so The lenses of the upper camera module SX and the lower camera module XX both face t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com