A printed circuit board and an intelligent terminal

A printed circuit board and wire routing technology, which is applied in the field of electronic equipment, can solve the problems that smart terminals cannot meet the thinning requirements and large area, and achieve the effect of meeting the thinning requirements, reducing the number, and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

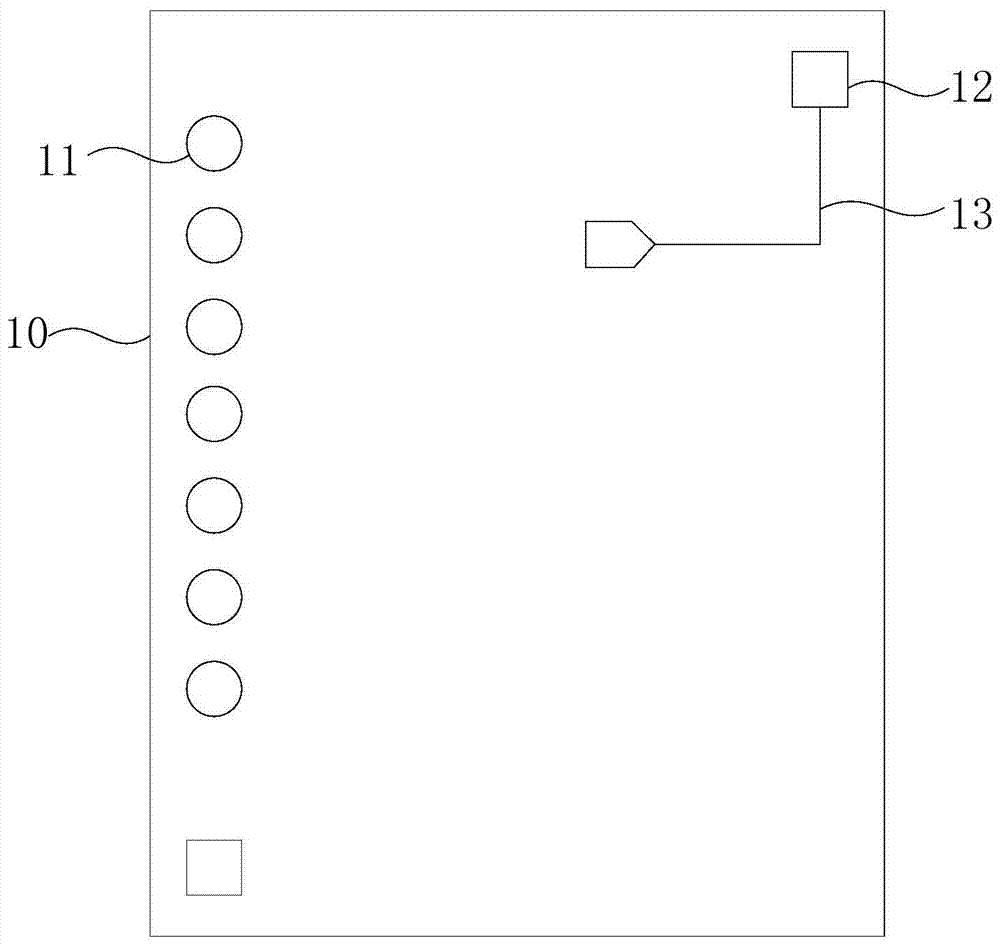

[0026] figure 1 is a schematic structural view of the printed circuit board provided in the first embodiment of the present invention. like figure 1 As shown, the printed circuit board includes an insulating substrate 10, on which a functional test line 13, a test point 11 and a cursor alignment point 12 are arranged, wherein at least one cursor alignment point 12 is compatible with the function The test trace 13 is electrically connected.

[0027] Wherein, each test point 11 in the printed circuit board is electrically connected to its corresponding functional test wiring 13, and the test point 11 is convenient for the test probe to conduct a functional test on the printed circuit board, such as the printed circuit board Check open circuit, short circuit and welding condition of all parts.

[0028] More than twenty test points may be included in the printed circuit board. For example, the printed circuit board of a smartphone can include the following test points11: 3 tes...

no. 2 example

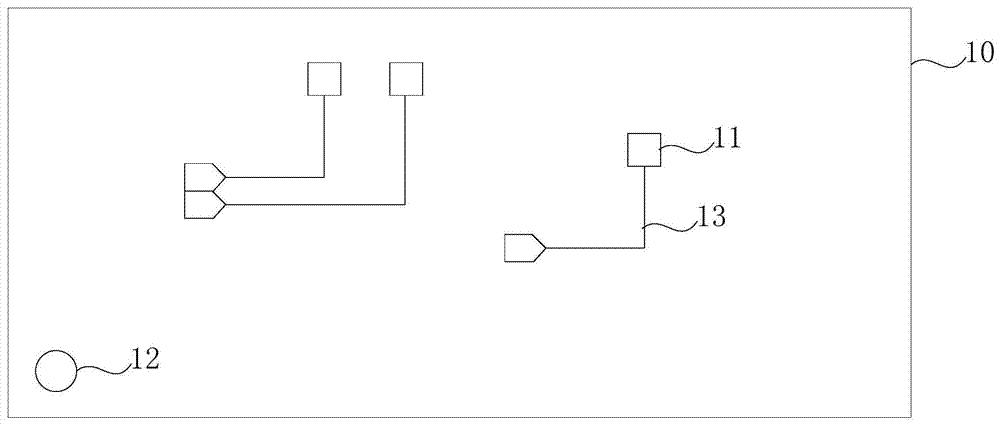

[0035] The printed circuit board provided in the second embodiment of the present invention includes an insulating substrate, and functional test wiring, test points, and cursor alignment points are arranged on the insulating substrate, wherein at least one cursor alignment point is aligned with the functional test Trace electrical connections.

[0036] Wherein, the printed circuit board may include a plurality of test points, and each test point is electrically connected to its corresponding functional test wiring, and the test points facilitate the conduction of the probes to realize the functional test of the printed circuit board.

[0037] Wherein, the front and back sides of the printed circuit board include two cursor alignment points respectively, that is, the printed circuit board includes four cursor alignment points in total, and the cursor alignment points provide a common possibility for all steps in the surface mount process. The measurement point ensures that the...

no. 3 example

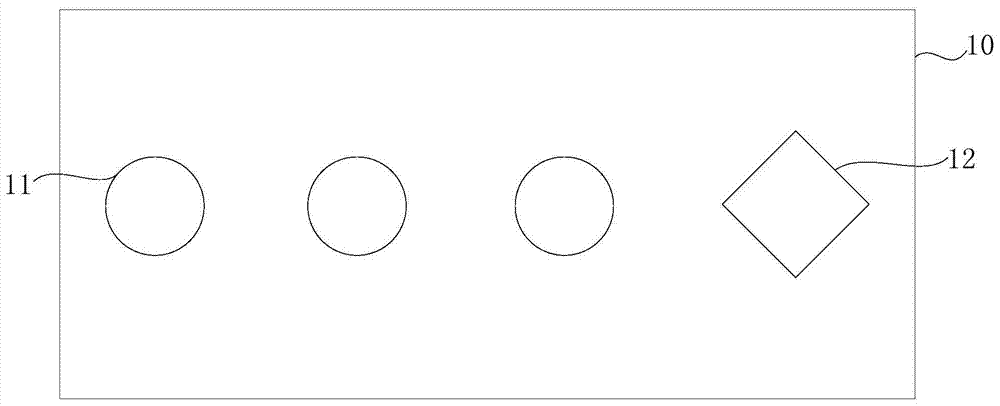

[0052] In the third embodiment of the present invention, the printed circuit board provided in the embodiment of the present invention is introduced by taking a printed circuit board including one cursor alignment point and capable of implementing three functional tests as an example. figure 2 is a structural schematic diagram of an existing printed circuit board, image 3 It is a schematic diagram of the circuit principle of the existing printed circuit board; Figure 4 is a schematic structural view of the printed circuit board provided in the third embodiment of the present invention, Figure 5 is a schematic diagram of the circuit principle of the printed circuit board provided in the third embodiment of the present invention.

[0053] combine figure 2 and image 3 As shown, in order to realize the three kinds of functional tests, three test points 11 need to be included in the existing printed circuit board, because the printed circuit board also includes a cursor al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com