Case for electronic devices

A technology for electronic equipment and shells, which is applied in the field of shells for electronic equipment, and can solve problems such as difficulty in obtaining appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

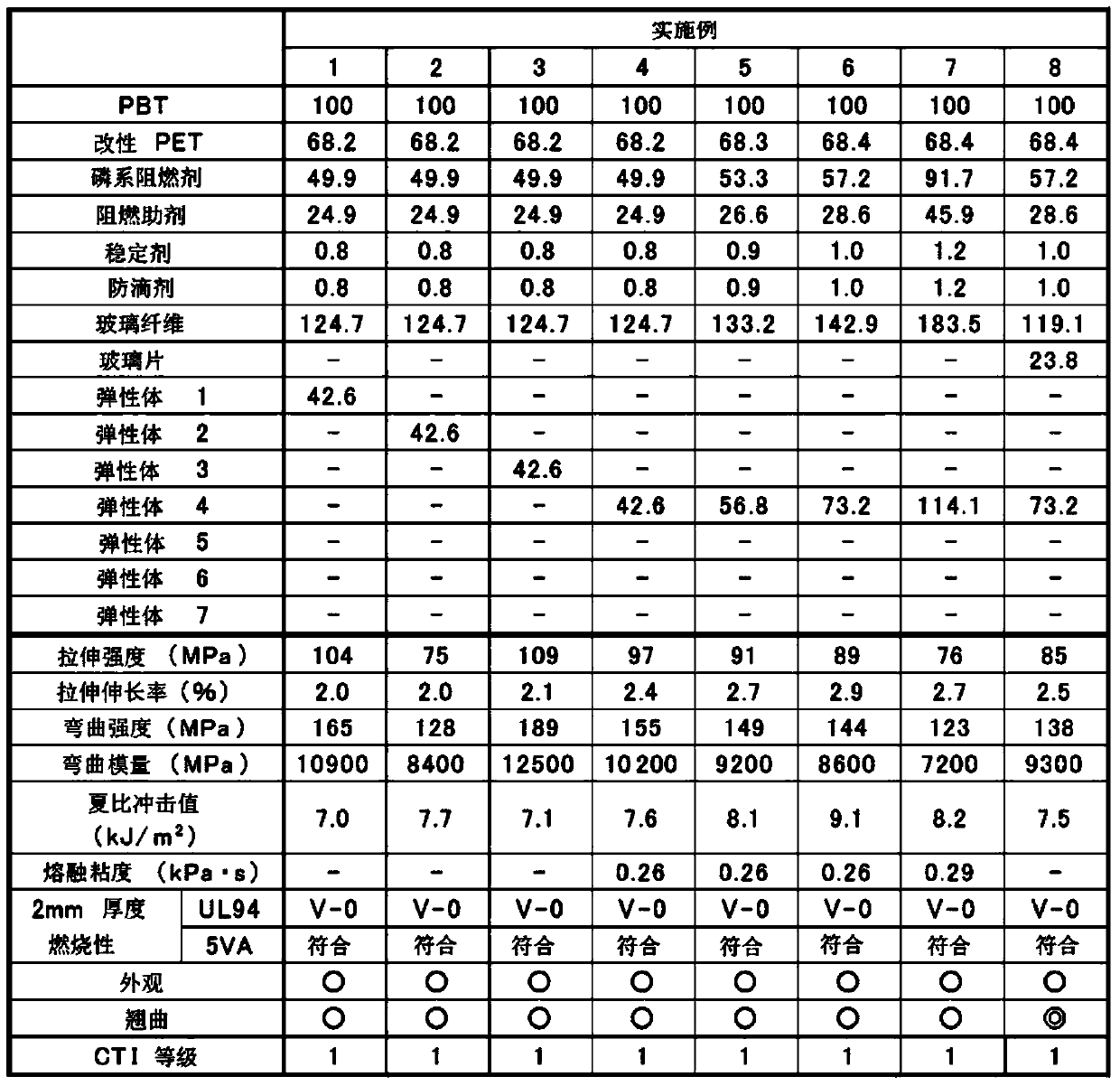

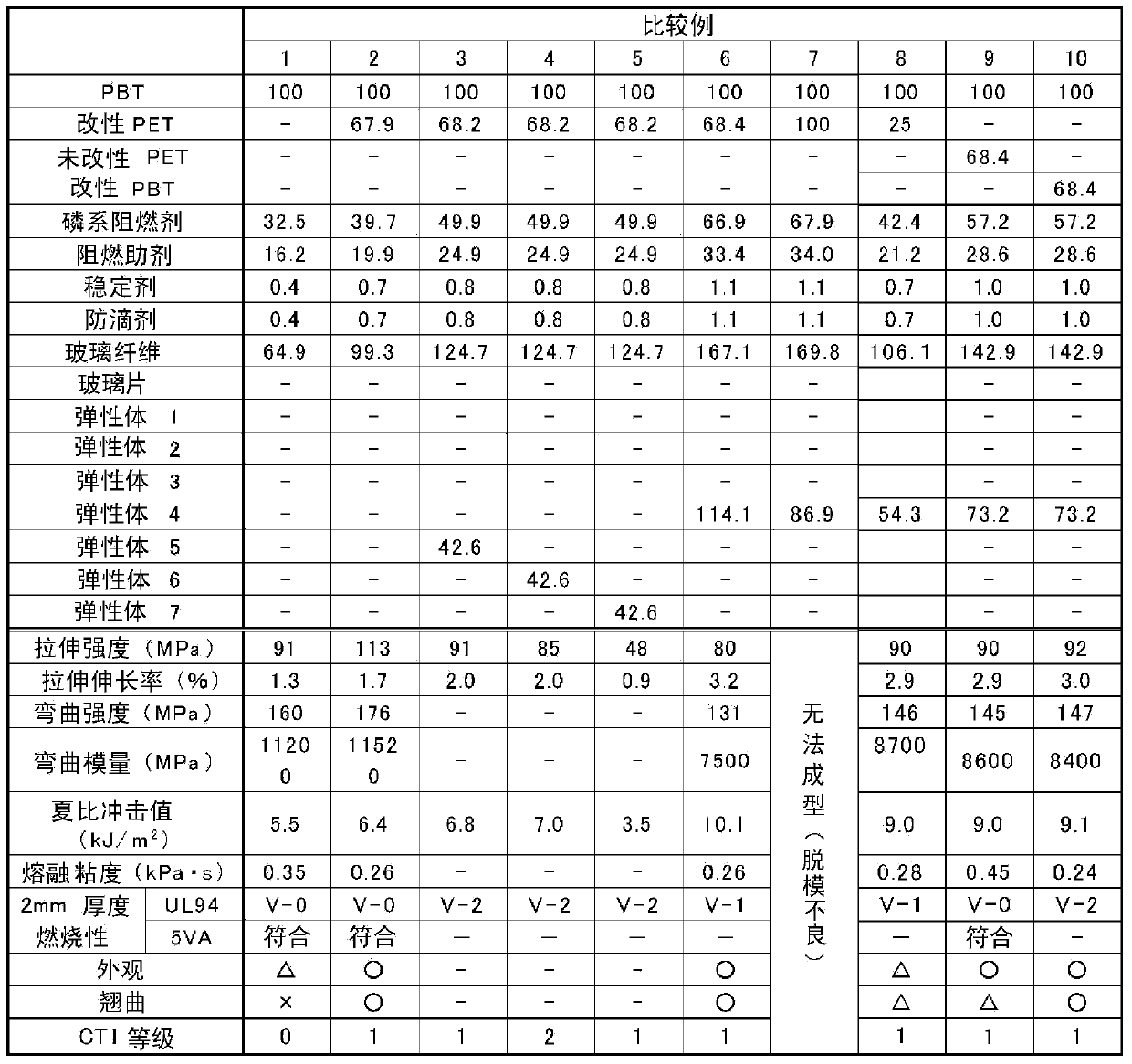

[0116] Hereinafter, examples are given and the present invention will be described in more detail, but the present invention is not limited by these examples.

[0117]

[0118] Details of each component used in Examples and Comparative Examples are as follows.

[0119] Polybutylene terephthalate (PBT); manufactured by WinTech Polymer.Co., Ltd., product name DURANEX (IV=0.8)

[0120] Modified polyethylene terephthalate (modified PET); manufactured using 12.5 mol% isophthalic acid-modified polyethylene terephthalate, TEIJIN FIBERS LIMITED

[0121] Polyethylene terephthalate (unmodified PET); manufactured by TEIJIN FIBERS LIMITED, product name TRF

[0122] Modified polybutylene terephthalate (modified PBT); Modified polybutylene terephthalate using 25 mol% isophthalic acid, manufactured by WinTech Polymer.Co.,Ltd.

[0123] Flame retardant; organic phosphate used, manufactured by Clariant (Japan) K.K., product name Exolit OP1240

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com